When it must be tight: Friction Stir Welding!

Tightness, Tightness, Tightness: This characteristic is essential when it comes to the design of components, such as heat exchangers, battery trays or cooling units. Long term resistant, solid, media and pressure-tight connections between workpieces are a must. When it must be tight, friction stir welding becomes the method of choice. Process reliable manufacturing of an adequate tightness is one of the most critical features and can be accomplished with the friction stir welding procedure. This modern joining technology, due to the procedure-inherent high degree of automation, is easily integrated into industrial series production.

Aluminum is gaining ground

During the friction stir welding, a solid phase welding procedure, no melt, pores or hot cracks occur, which often can cause leakages in conventional fusion welding. This effect is increased with aluminum cast material, which has become a standard for many designs and components of liquid cooled systems in industries, such as automotive, power transmission/power electronics, battery manufacturing, rail vehicle construction, aerospace technology and consumer electronics. Especially in the case of material-locking joining of aluminum and aluminum alloys, such as metal sheet and cast material, the friction stir welding procedures show their benefits and achieve high-quality joints with excellent surface quality; time consuming rework, such as deburring welding seams become obsolete.

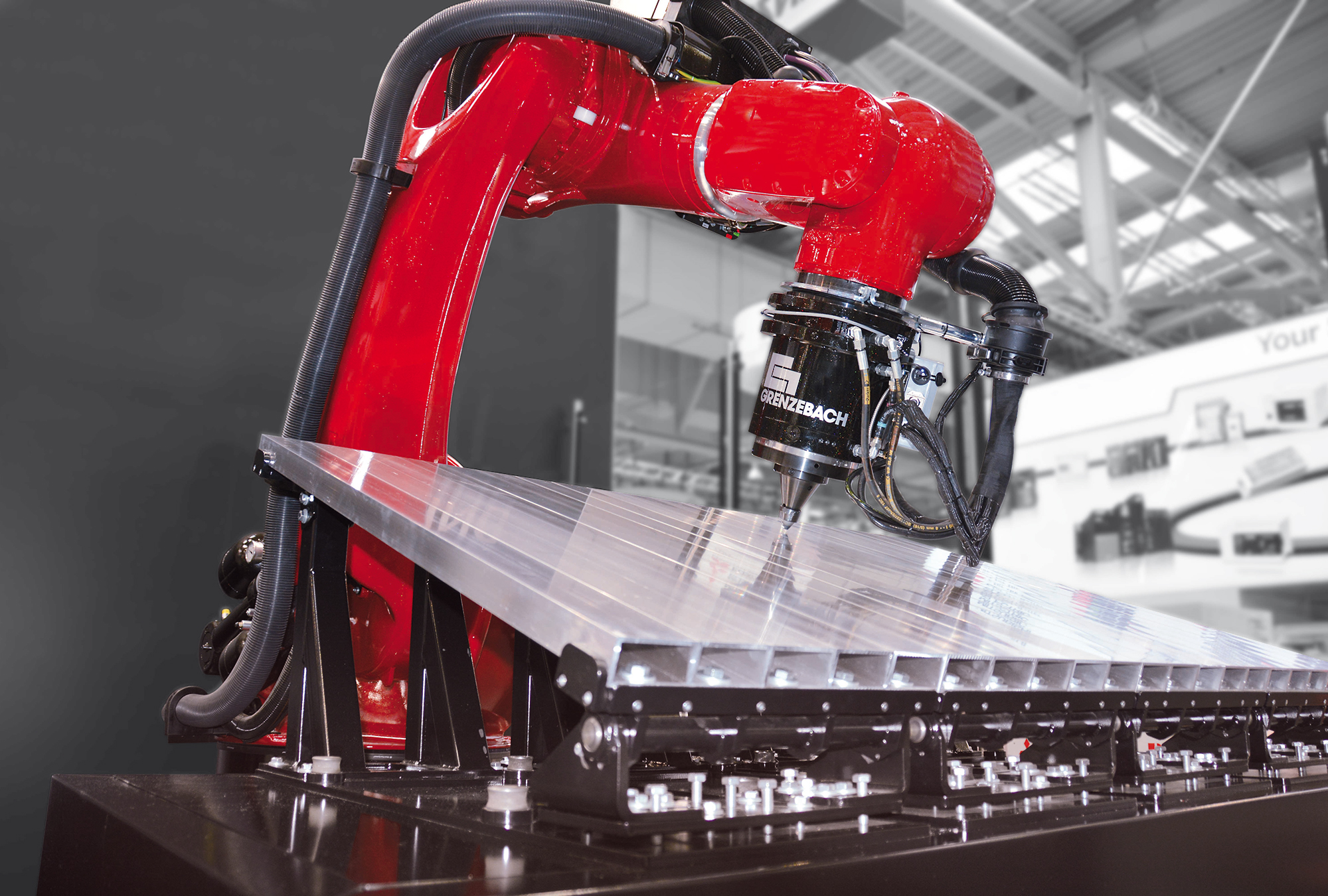

Friction Stir Welding - stirred, not melted

During the friction stir welding procedure a rotating, wear-resistant friction pin creates heat next to the joint. The material is plastically deformed and stirred along the joint by the friction pin without reaching the melting point of the material. The plasticized material is condensed above the tool shoulder and a solid, media and pressure-tight connection is created between the workpieces.

Compared to conventional fusion welding procedures, such as arc welding, friction stir welding does not require welding wire, protective gas or complex venting systems. Also, this welding technique does not generate any discernible vibrations, noise, emissions or optical radiation.

Finish with brilliance

Welding is often the very last step in the process chain. If any leakages occur along the way, the entire product is lost. For those who invest in FSW technology, also invest into a safe termination of the process chain. Effortless process termination and tightness, which can be achieved easily and with high reproducibility; this makes equipment investment in the FSW sector so promising.

With a comprehensive approach to industrial serial production

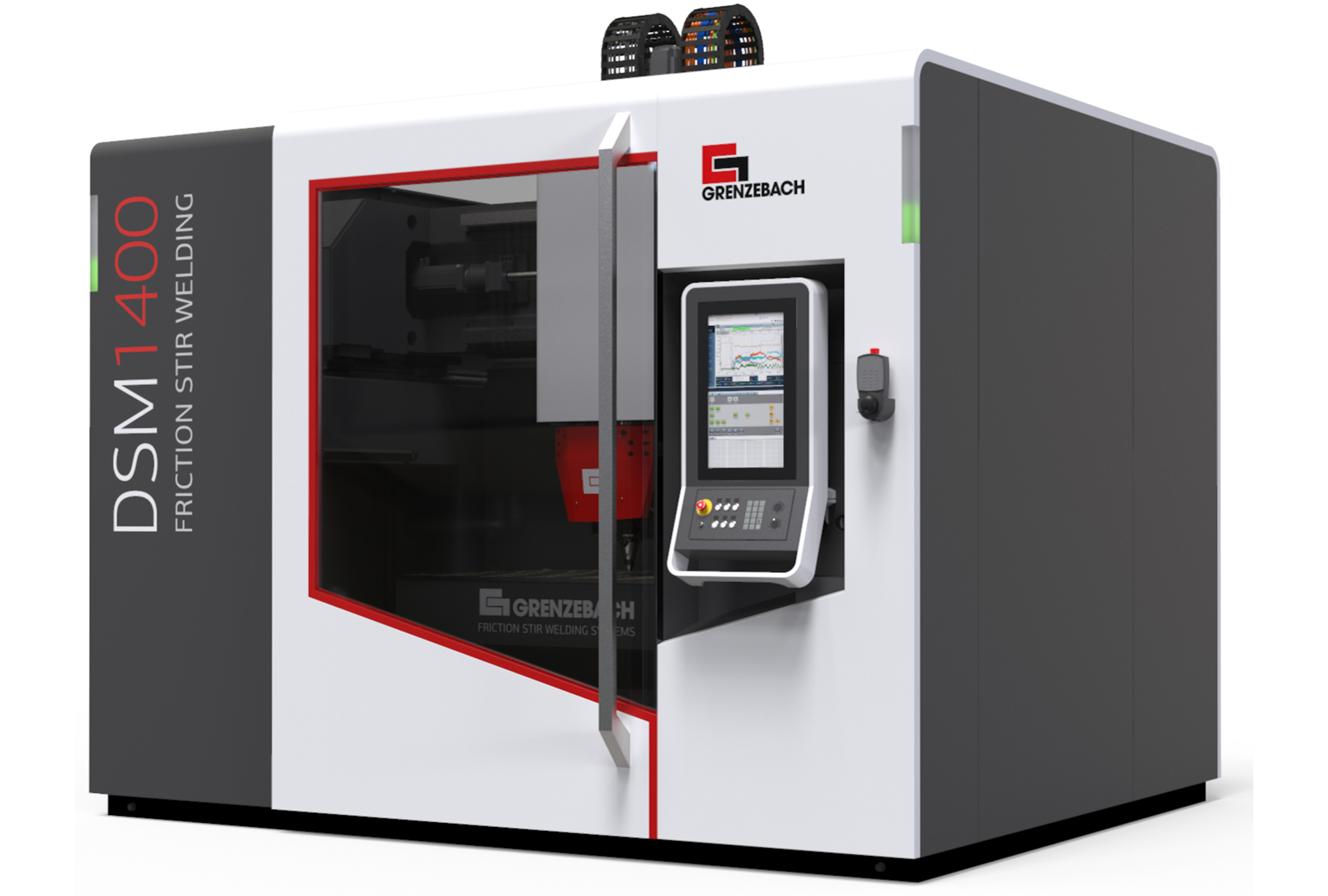

Higher production volumes in many industry sectors can be met by ever shorter cycle times of FSW technology. Besides that, all secondary processing times shall be reduced to a minimum in order to save useful cycle time. For this purpose, re-positioning of components as well as loading and unloading of machinery is done fully automatically. The new FSW machinery generation DSM1400 & DSM2400 by Grenzebach was showcased for the first time at the "Schweißen & Schneiden 2017" in Düsseldorf. It has a modular design and can be extended for various component supply systems. Thanks to the two mobile prestressing units, the second unit can be loaded and unloaded concurrently to the welding operation. The machinery can keep executing welding jobs; idle running is reduced to a minimum.

As system integrator and provider of friction stir welding with many years of experience, Grenzebach supplies FSW overall process solutions for industrial series production. The comprehensive approach from Grenzebach includes, besides the welding equipment and delivery of welding units, the process development for the respective customer application as well as provisioning of adapted friction stir tools.

Grenzebach is a world-wide leader specializing in the automation of industrial production lines. By providing services encompassing the entire life cycle of a project, Grenzebach’s tailor-made automation solutions have a positive impact globally in glass and building material manufacturing as well as intralogistics. Many years of experience, continuous development, and sustainable support services are what makes Grenzebach one of the most preferred partners world-wide. 3000 installed lines in 55 countries prove that the Grenzebach name stands for quality and reliability. Amazingly, 90 percent of Grenzebach’s products are for export which reflects that the medium sized family-owned company from Hamlar is a global player in the industrial automation.