Grenzebach: future-oriented automation specialist

Thinking ahead markets and products

Do you want to enhance the efficiency and productivity of your processes? You came to the right place because the world of industrial automation is Grenzebach’s home.

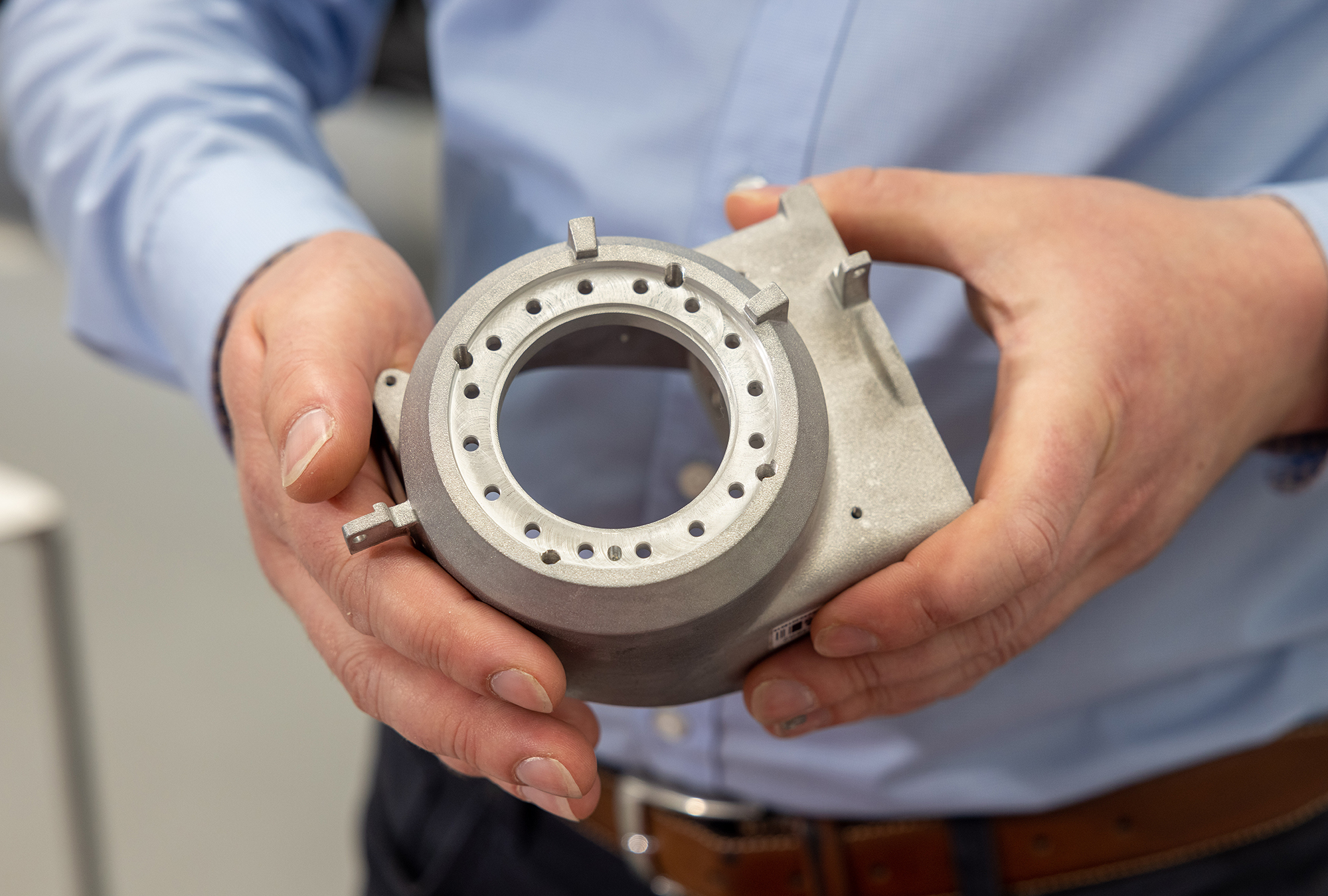

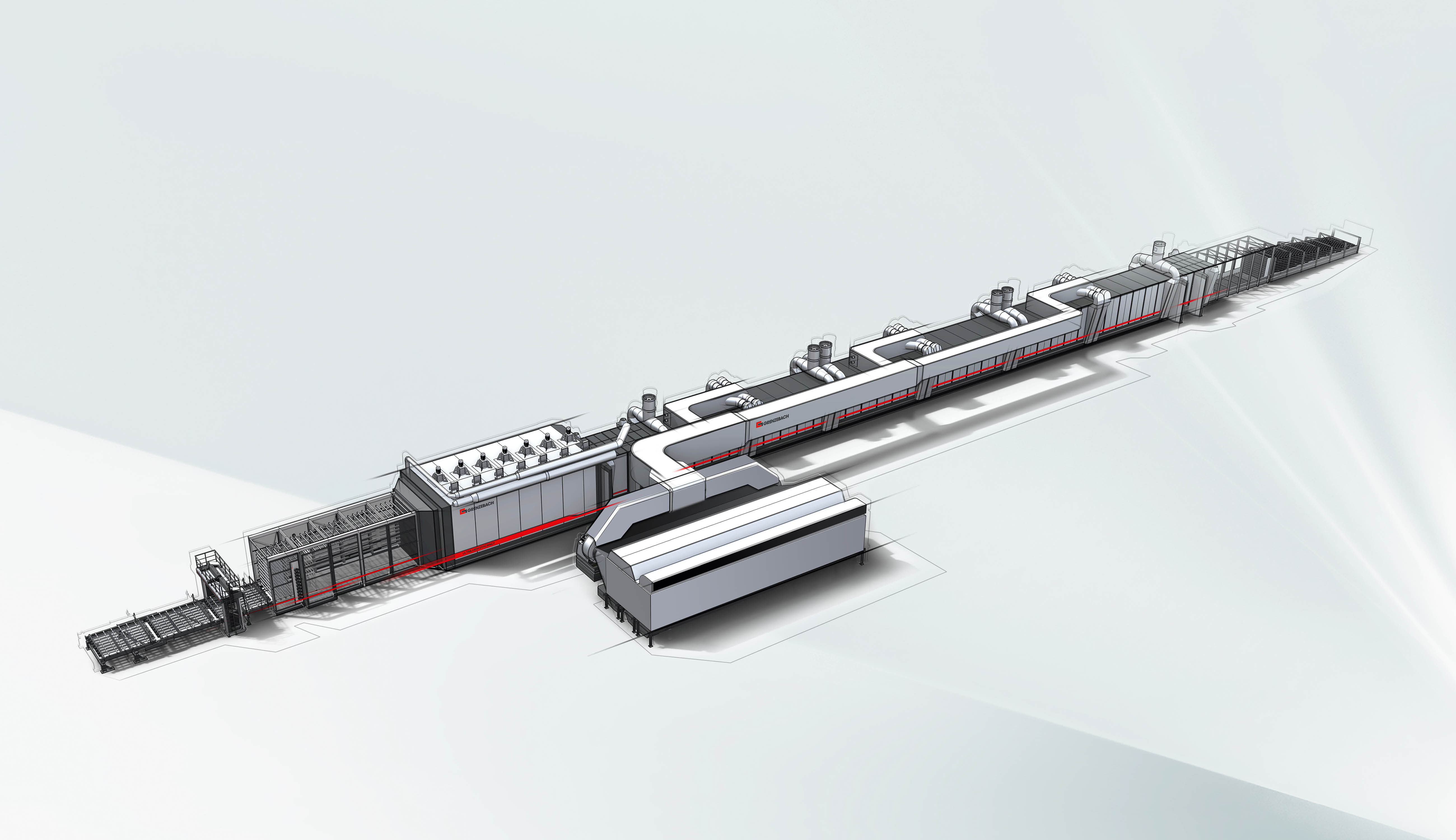

We provide solutions for the global glass, building materials and intralogistics markets. In addition – together with you – Grenzebach develops new application areas, such as recycling processes,friction stir welding, the automation of industrial additive manufacturing,digital networking, sustainable energy generation or solutions for processing bulk solids and powders.

installed plants in 55 countries stand for quality and reliability.

employees who do their utmost every day to ensure your success.

years of experience are the foundation on which we build our innovations for tomorrow’s markets.

Well positioned for your goals: the Grenzebach Group

COMPREHENSIVE SERVICE FROM A SINGLE SOURCE

Success usually requires more than just one competence. That’s why Grenzebach bundles complementary know-how, including entrepreneurial skills. With the Grenzebach Group, the interconnected know-how of leading technology experts is available to you whenever you need it.

- CNUD EFCO and Grenzebach joined their competencies in glass production to provide customers with the essential components of the glass manufacturing process from a single source.

- inos Automationssoftware GmbH specializes in image processing and laser technologies for demanding applications in various industries.

- Millennium Control Systems is Grenzebach’s partner for sophisticated control and software solutions for a wide range of industries, especially for American market requirements.

With a global business unit structure and worldwide locations, we are always strategically close to you. Central contact persons provide that you can make optimal use of the Grenzebach Group’s synergy effects.

Worldwide contact

Grenzebach Group worldwide

By loading the map, you agree to Google's statement of privacy protection.

Here you can find out more what this means for the protection of your personal data.

Contact us any time

We’re happy to help you!

Collaboration means dialogue. We support you no matter where you are in the world. Contact us. Send us your inquiries. We're looking forward to hearing your ideas.