Our service for the wood industry

We live service. Around the clock. Around the world.

From years of experience in personal contact with more than 400 customers in veneer production worldwide we know that maximum availability and performance of the plant are in focus. We have made that our mission so that you can concentrate fully on your core business. With our customized services and uncomplicated service solutions for the woodworking industry we are a service partner you can rely on 100 %, throughout the entire lifecycle of a plant. We can offer you integrated service concepts because our specialists are experts in their field and stand out for their profound product-related know-how. We commission your plant on schedule, and we keep our service promise after that, during the entire utilization phase. In addition to worldwide spare parts supplies and upgrades we ensure equipment performance and sustainability of your plant.

Grenzebach's service modules for the wood industry.

A one-stop solution.

Original Parts

Ensure top performance,

value due to durability,

cut downtime:

- Excellent quality

- A one-stop shop

- Consistent production

- High levels of availability

- Quick lead times for spare parts

- Professional customer support

- Long service lives

- Supplied worldwide

Excellent Services

Optimize technology availability,

keep output constantly high

and make usage sustainable:

- 24/7 hotline

- Remote support online

- Health checks

- Preventative maintenance

- Training for customers

- On-site service

- Flexible service agreements

- Extended warranty

Rolling Upgrades

Keeping plant performance at a permanent level,

raise plant productivity and

extend lifecycle:

- Process optimization

- Plant overhaul during production

- Modifications to hardware and software

- Engineering consulting

- Disassembly and reassembly of machinery and parts if company relocates

- Customized, automated retrofits

- Energy saved due to new technologies and machine applications

- Plant audit and reassessment of the safety concept

- Upgrading safety components to the state of the art

Future Services

Use Grenzebach’s SERICY

digitalization platform and benefit

from smart, robust processes:

- Predictive maintenance

- Collaboration app

- Clear reporting

- Detailed statistics

- Advanced analyses

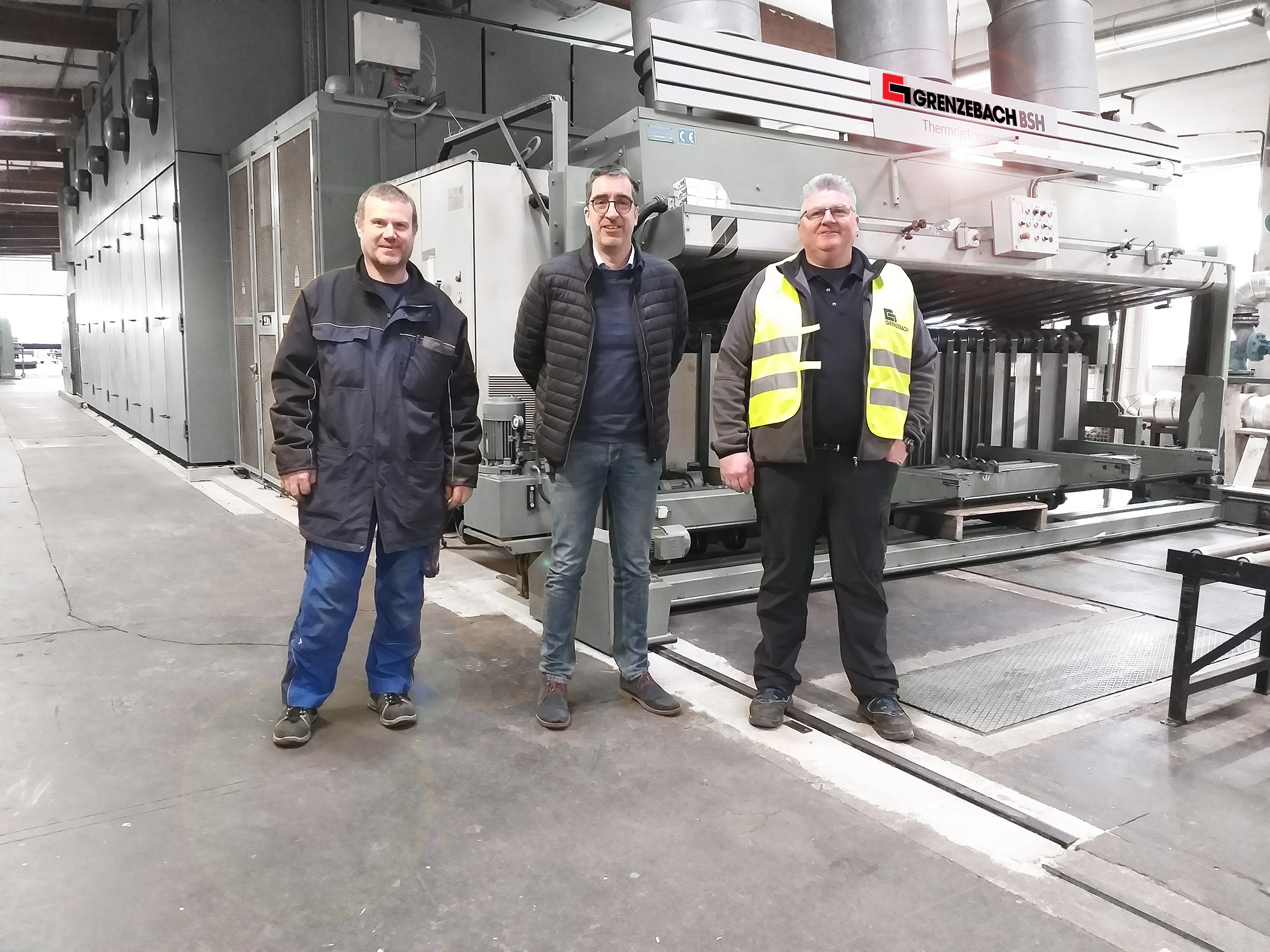

Service highlight

What customers say about our service

“For many years, we have been working together with the Grenzebach service team in a spirit of trust.

In case of malfunctions or modernizations, the Grenzebach service technicians are on site at short notice. For fast troubleshooting, the Grenzebach service professionals identify and analyze the causes and repair the plant with us.

Through continuous modernization, we can be sure that the efficiency and safety of our plants are constantly improved by keeping systems and software up to date. This minimizes high repair costs or operational interruptions in advance.”

Fritz Kohl GmbH & Co. KG

Furnierwerk

97753 Karlstadt

“With Grenzebach as our partner, we are always comprehensively and foresightedly advised. Already during the project phase in 1997, our capacity requirements were realized in confined space. Today, foresighted plant upgrades protect our production from unplanned downtimes.”

AS Latvijas Finieris

Customer since 1997

Your contact persons

Nothing beats personal and direct contact. Our wood specialists will be happy to answer your questions on all service topics.