Intralogistics in the automotive sector

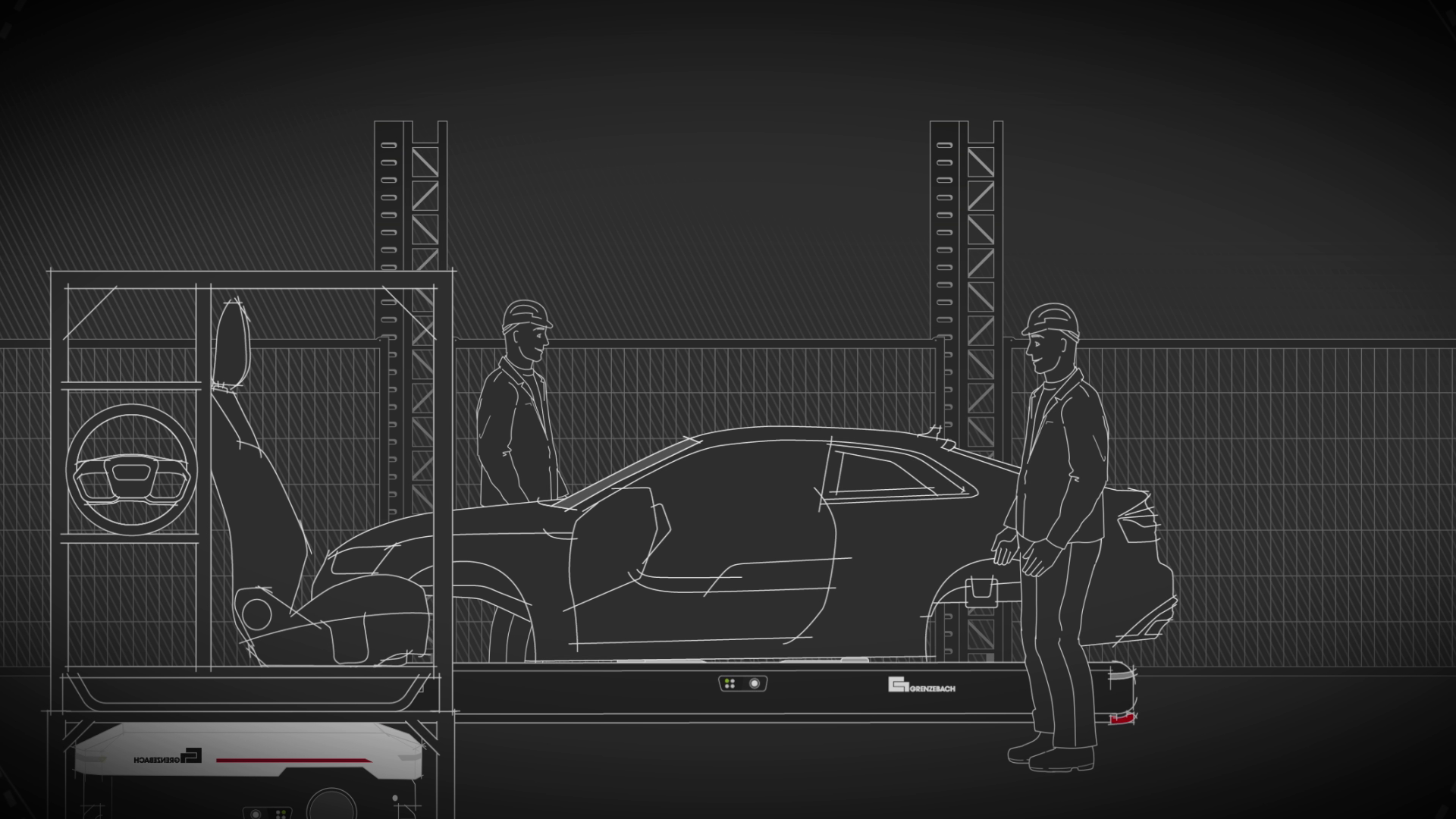

For the automotive industry, Grenzebach offers several intralogistics solutions that enable optimized production logistics. Our automated guided vehicles (AGVs) ensure reliable, flexible, and efficient production. Regardless of whether it is just-in-sequence provision of components or commissioning of individual components: Grenzebach's intralogistics solutions move the automotive industry forward. For the automotive industry, Grenzebach offers several intralogistics solutions that enable optimized production logistics. Our automated guided vehicles (AGVs) ensure reliable, flexible, and efficient production. Regardless of whether it is just-in-sequence provision of components or commissioning of individual components: Grenzebach's intralogistics solutions move the automotive industry forward.

Grenzebach’s solutions for the automotive industry include, among others:

Automated guided vehicles (AGVs) for optimal transport routes and maximum availability

Software for reliable coordination of vehicle movements

Load carriers for easy and flexible accessibility

Peripherals such as loading and transfer stations

When no two car orders are the same

SUCCESS STORY

At a well-known German premium car manufacturer, a Grenzebach solution for automated goods transport increases the reliability of just-in-sequence production.

SUCCESS STORY

NEWS & PRESSE

In 2020, the Porsche facility in Leipzig received the Logistics Award of the German Association of the Automotive Industry (VDA). A Grenzebach solution for Automated Goods Transport is part of this logistics concept.

Solution portfolio:

Use your potential and contact us now:

Your contact person: Tom O'Donnell

You would like to find out more about how your company can benefit from driverless transport systems in intralogistics?