Discover the automation potential of your 3D printing equipment now.

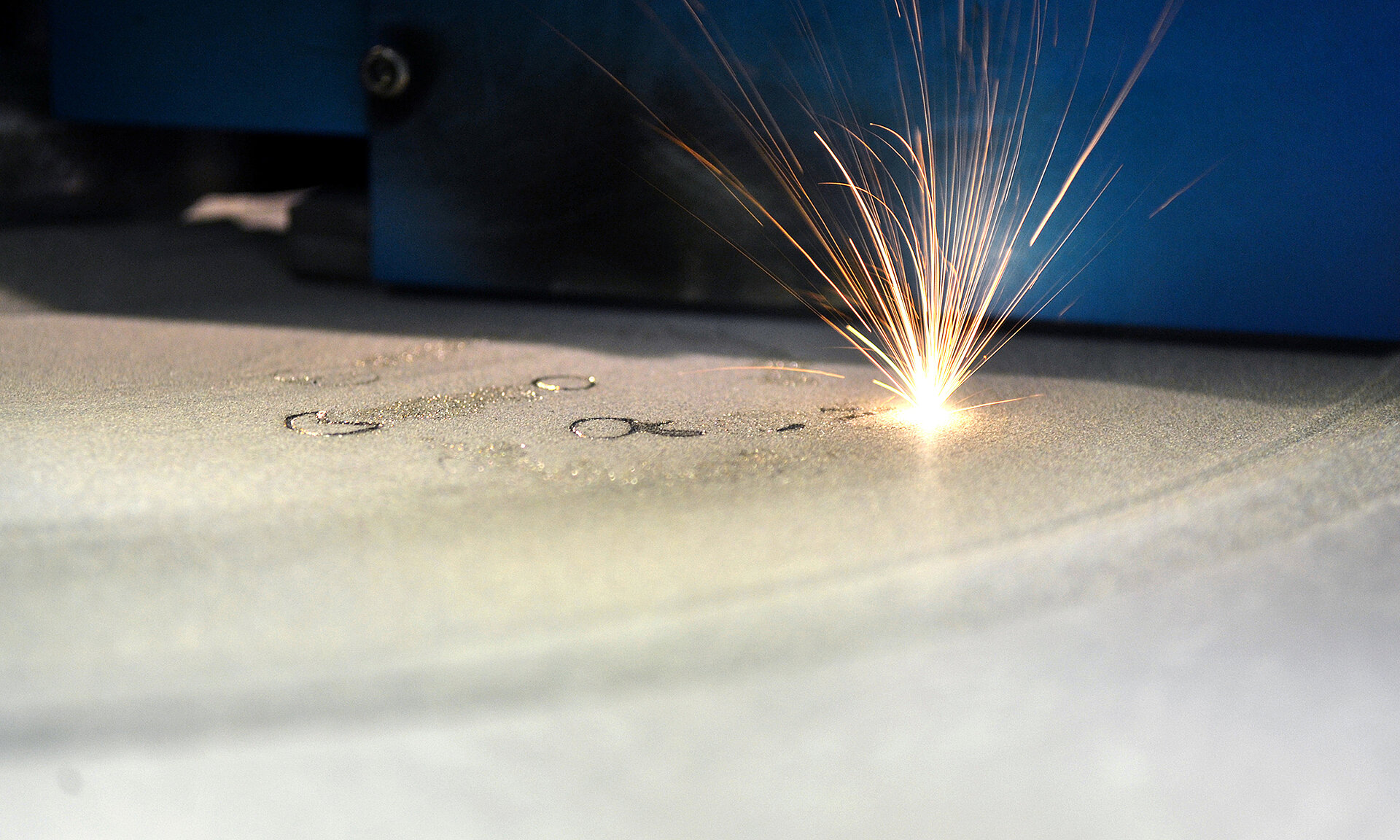

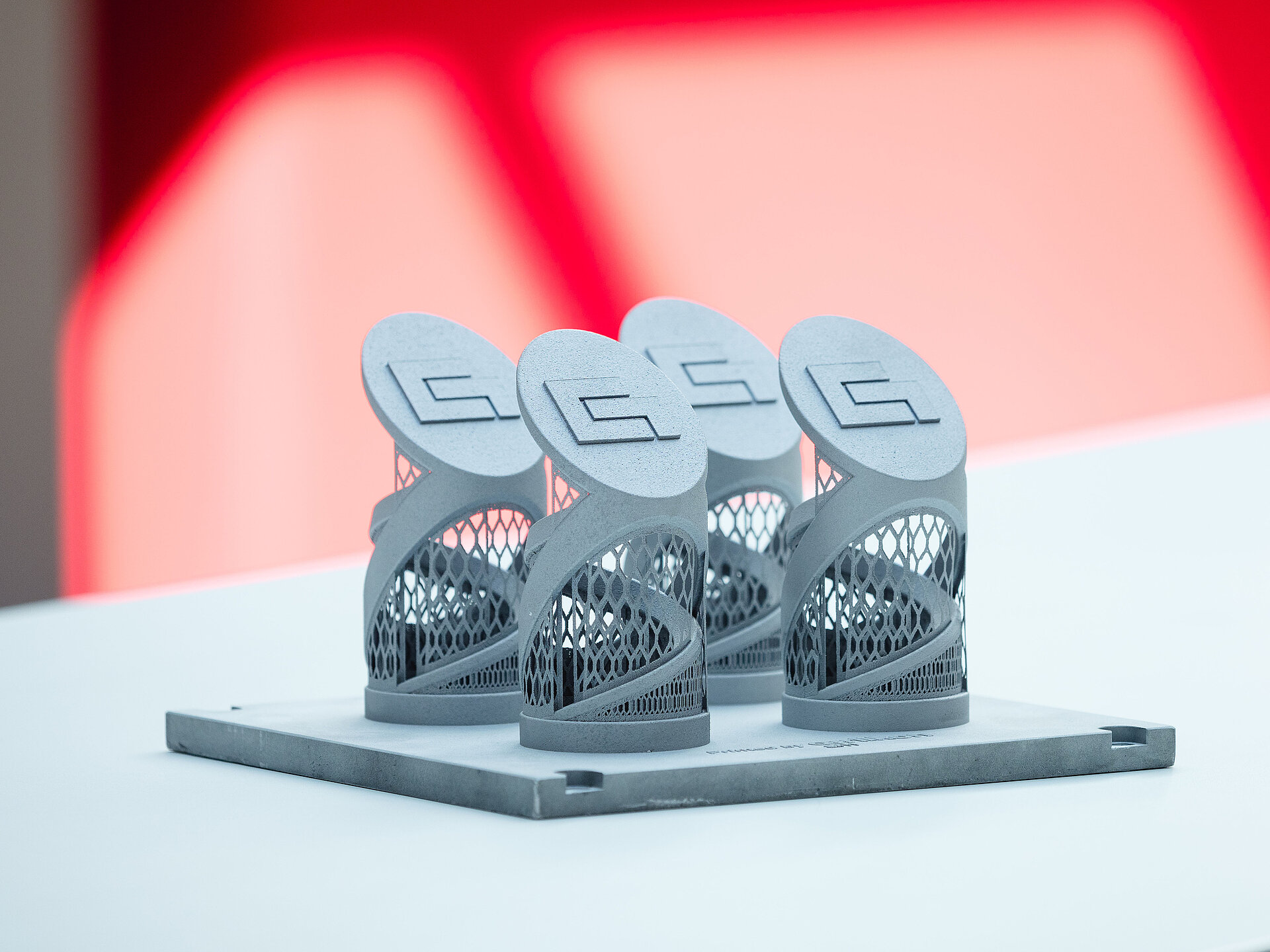

Embark on serial production with additive manufacturing: with innovative solutions by Grenzebach, you can optimize your workflow for metal or polymer components by efficiently utilizing your 3D printing equipment. Simultaneously, you are establishing a working environment with the highest safety standards.

“For manufacturers and users of 3D printing equipment, we network the various working steps in additive manufacturing processes. By automating the processes, we achieve an optimal production flow and thus efficient utilization of the equipment. In addition, our solutions make working environments safer.”

Customized automation solutions

We develop automation solutions that are precisely tailored to your needs by analyzing your requirements and developing a customized concept for automating your additive manufacturing. In doing so, we integrate existing machines into the optimized manufacturing process.

Our services for you:

- Consulting and needs analysis

- Simulation and software development

- Project management and training

- Installation and commissioning worldwide

- Flexible worldwide service and support

About Grenzebach

Organizing complex processes intelligently and thinking ahead in automation are two of our strengths. Rely on our more than 60 years of experience in the automation of industrial processes in various industries.

Read more about our company.