This website uses services for operation, statistical analysis, display and sharing of content from social networks and interest-based advertising. These services make the website usable, improve your browsing experience, enable interactions with networks and show relevant advertising messages. Activate the desired services in the respective categories to accept them. More information

By clicking on "Submit" or "Select all and submit", you agree that your data will be processed by the corresponding services.

The activated services do not affect your browser configuration. Depending on the browser configuration, cookies from these services are deleted when the browser is closed or must be deleted manually if they are not to be valid beyond the specified time period.

By activating the respective services, you consent to us providing you with information and offers on social media, search engines, or display networks, potentially across devices. You can withdraw this consent at any time, free of charge and without formal requirements. Only the transmission costs according to basic rates apply (e.g., phone, fax, email, postage).

您的联系方式

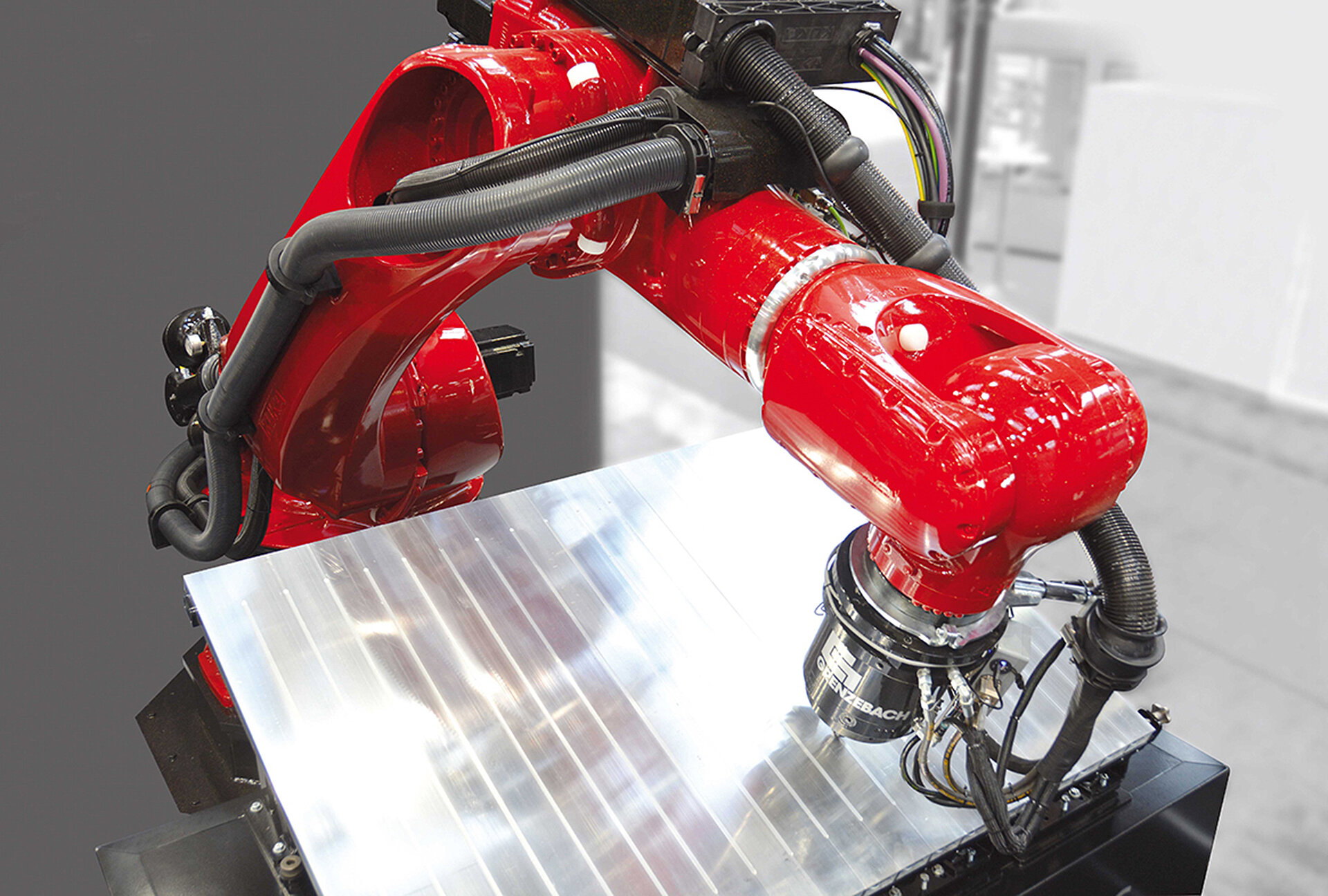

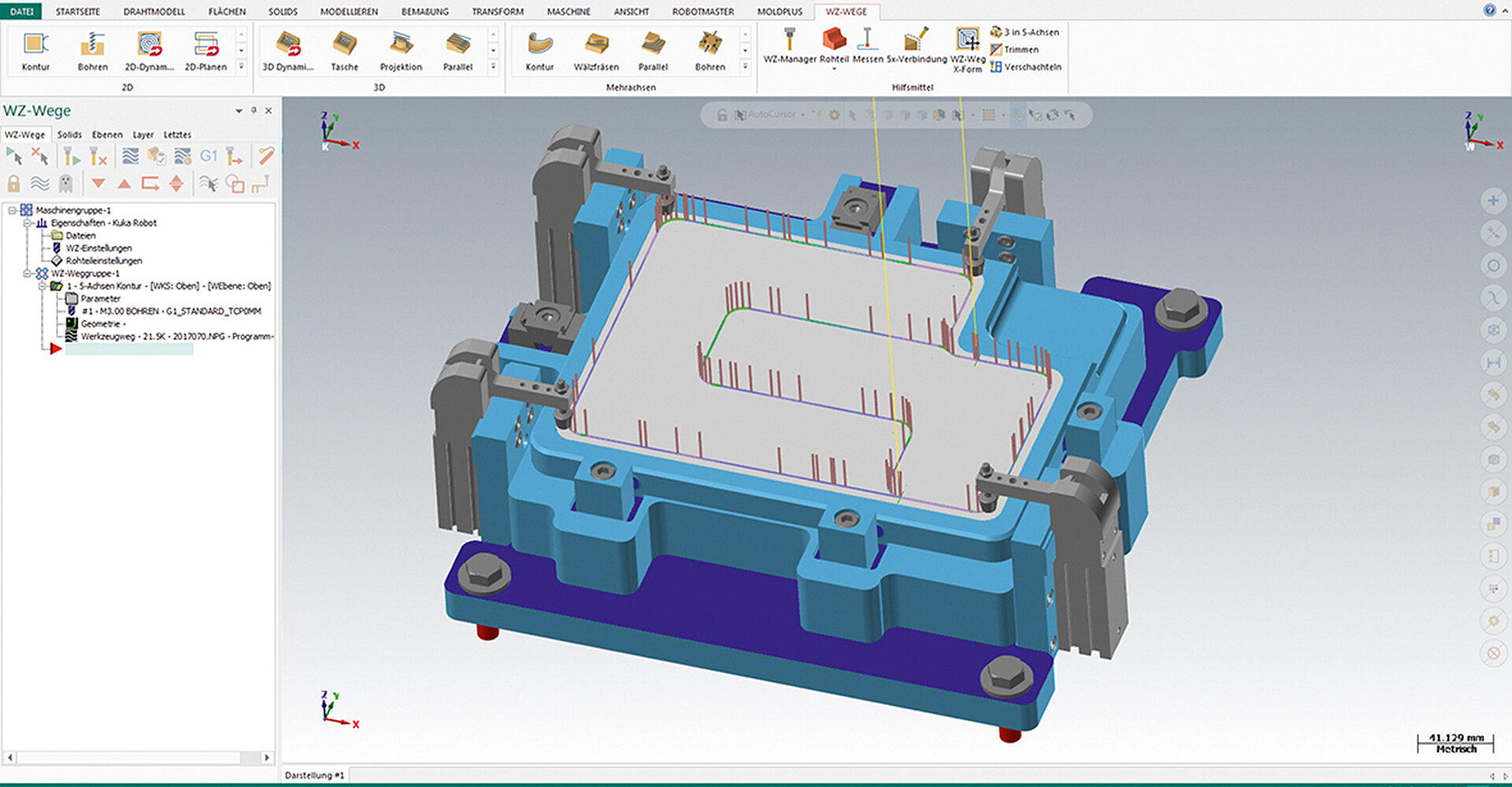

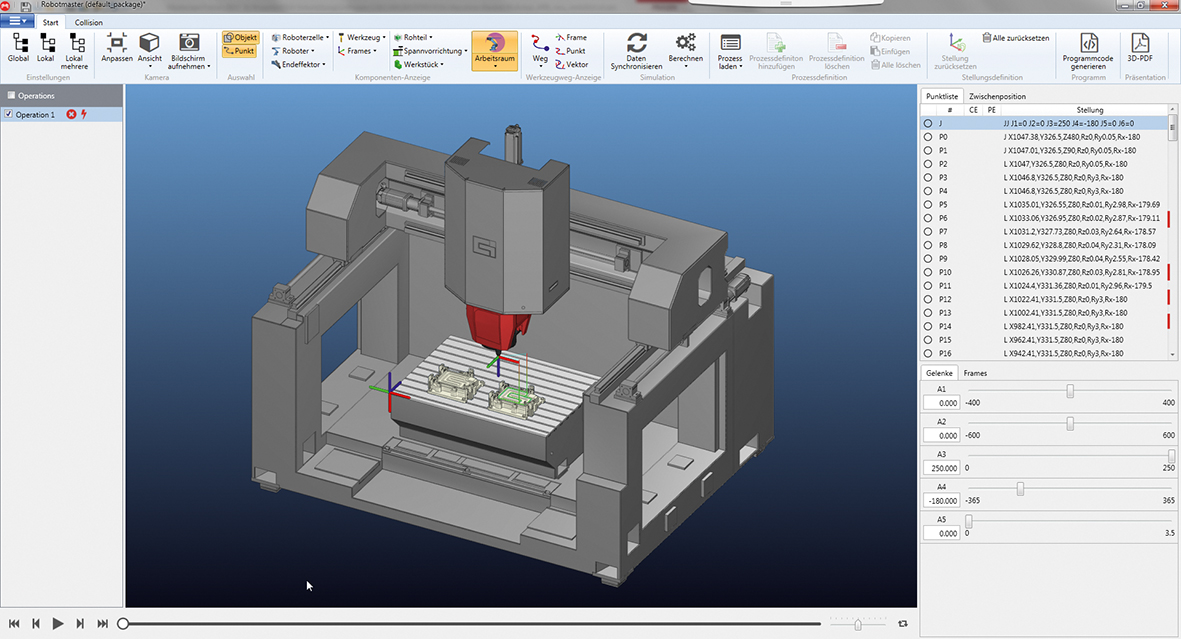

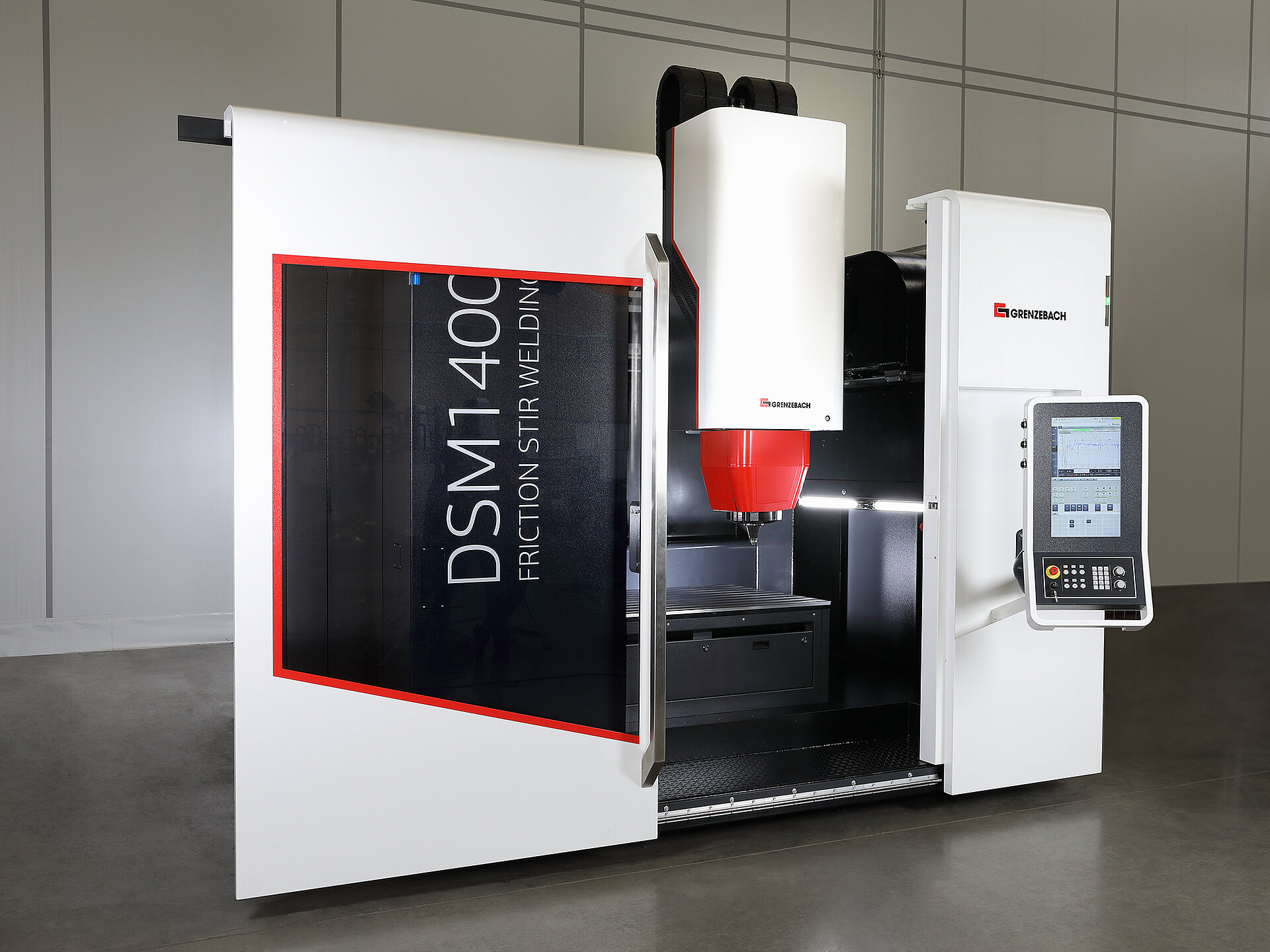

Grenzebach