Autonomous Load Carriers (ALCD) in Intralogistics

Sensors in the vehicle detect the contours and actual position of the goods carrier. The goods carriers are part of the logistics process and are managed by the Warehouse Control System and Fleet Manager. The Fleet Manager is our software solution used in intralogistics to control and optimize the material flow in factories and warehouses.

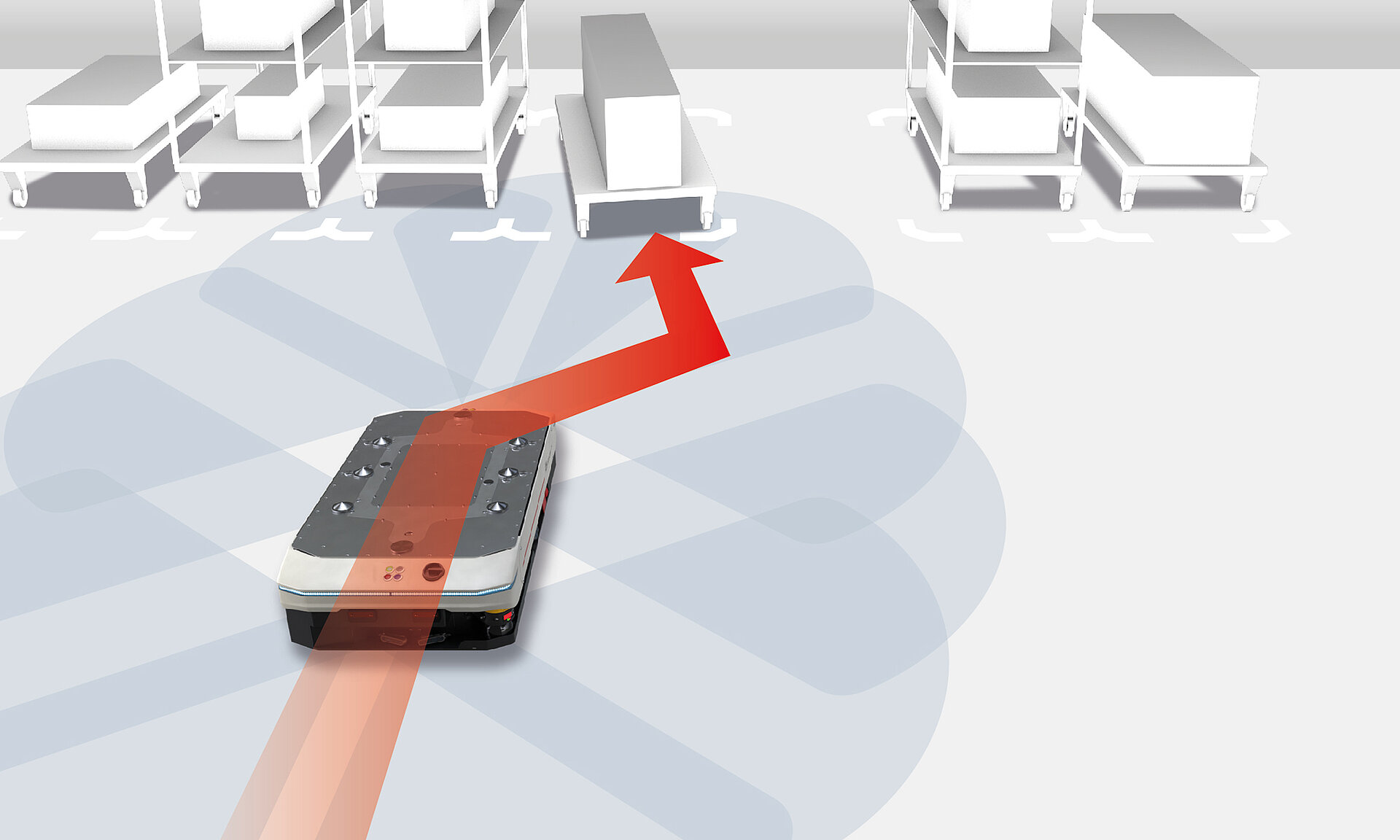

Without autonomous load carrier detection (ALCD), the load carriers must be stored in the exact positions configured in the layout, whereas with ALCD the load carriers can be easily moved from the configured position without adjusting the position in the layout. An intelligent algorithm, which is started when entering a storage location, detects the actual position of the goods carriers and adjusts the travel path of the AGV.

The use of autonomous goods carrier detection can improve the efficiency and accuracy of warehouse and logistics processes. This leads to a reduction in labor costs and to the elimination of mechanical station installations, higher productivity, and faster processing time. If you decide to use Grenzebach's ALCD technology, you have the option to flexibly design the unloading and loading station locations.