Automated Guided Vehicles for Optimized Intralogistics Processes

Discover the Advantages of Autonomous Transport Systems Now

Maximize the efficiency of your company by using intralogistics solutions by Grenzebach. An optimized material flow noticeably increases your productivity: We offer solutions that move you forward, make your working environment sustainably safer and processes more efficient!

Table of Contents:

Our Vision

Intralogistics solutions from a single source with reliable service: Trust our years of experience in automation solutions and rely on the quality of German made products and engineering.

years of expertise

installed system environments

automated guided vehicles in operation worldwide

locations in Germany, USA, Romania, and China

FAQ

Why Are Intralogistics Processes Being Automated?

Advantages

Efficiency:

Workflows and material flows are optimized by using AGVs for intralogistics processes.

Autarky:

AGVs by Grenzebach support your skilled workers and ensure flexible operations 24/7.

Occupational Health and Safety

Ergonomic processes reduce the strain on your employees.

Flexibility:

Automated systems are easily scalable and can adjust to fluctuations in production demands.

Safety:

AGVs can take over operations in hazardous environments and protect your employees from safety risks.

Reliability:

AGVs work reliably and ensure that goods are in the right place at the right time.

“At Grenzebach, we believe that automating logistics processes with automated guided vehicles offers the best balance between flexibility and efficiency in many use cases. Our solutions take a holistic approach and include hardware, software and service - all from a single source.”

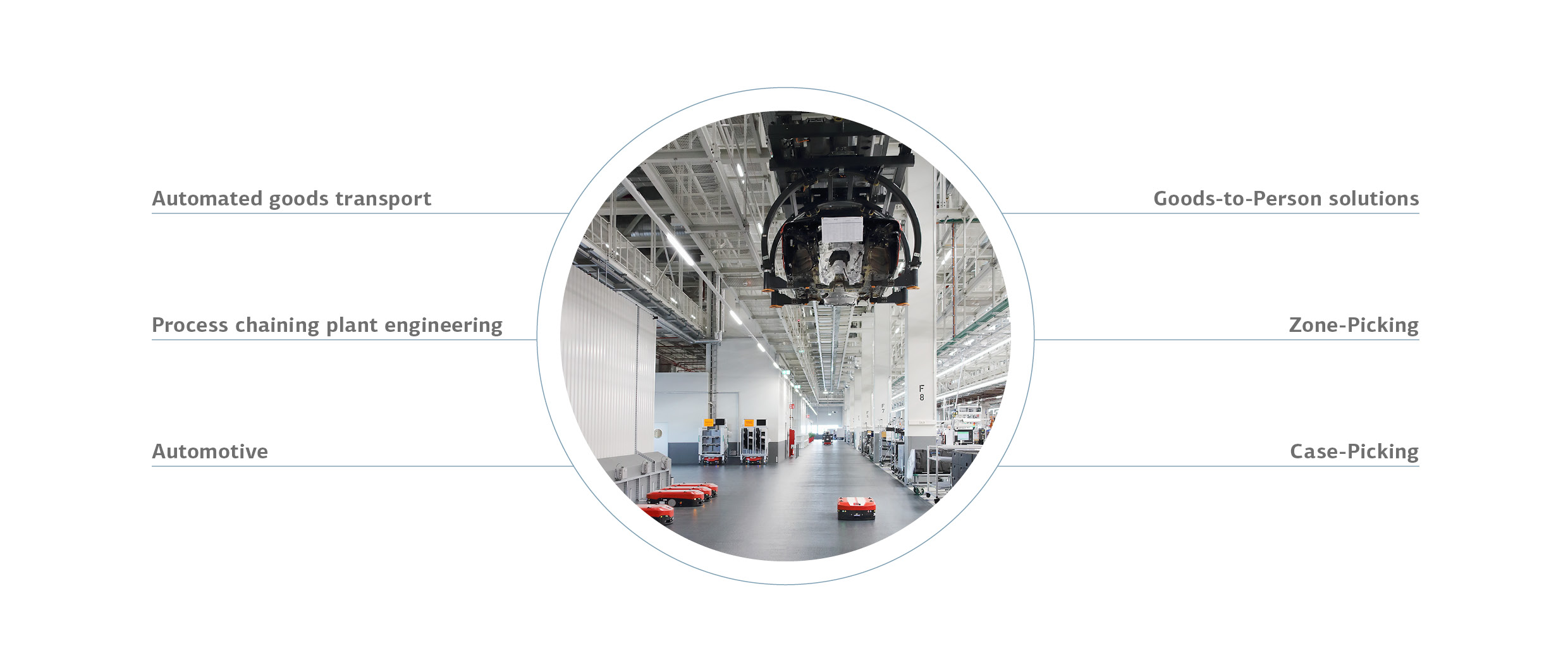

Use Cases for Intralogistics Solutions by Grenzebach

We offer solutions that are tailored to your exact requirements. Learn more about our solution profile for the following areas:

Goods-to-Person

Automated processes in commissioning increase your company's efficiency: Automated guided vehicles from Grenzebach independently transport goods and products from one place to another.

Automated processes in commissioning increase your company's efficiency: Automated guided vehicles from Grenzebach independently transport goods and products from one place to another.

Grenzebach Service Round the Clock

We are here for you - anytime, anywhere. As your partner and companion for intralogistics solutions, we consistently think ahead for your solutions and offer you excellent and reliable service throughout the entire life cycle of your systems.

Downloads & Links

More information

We Support You in the Automation of Your Processes

Your Contact Person: Michael Blood

You would like to learn more about how your business can benefit from automated guided vehicles in intralogistics?