Fabrication, Assembly, Testing & Build-to-Print = Contract Manufacturing

Rethinking processes for assembly and parts production

There are many reasons to make use of our contract manufacturing. First and foremost, of course, it is a matter of economic efficiency. Shorter and shorter delivery times, lack of internal production capacities and rising personnel costs can be further reasons to consider outsourcing production.

This is the point at which you can hand over the responsibility for your product to us. From engineering to series production of parts or assemblies, we are an experienced partner. Whether pure manufacturing or new development including product management.

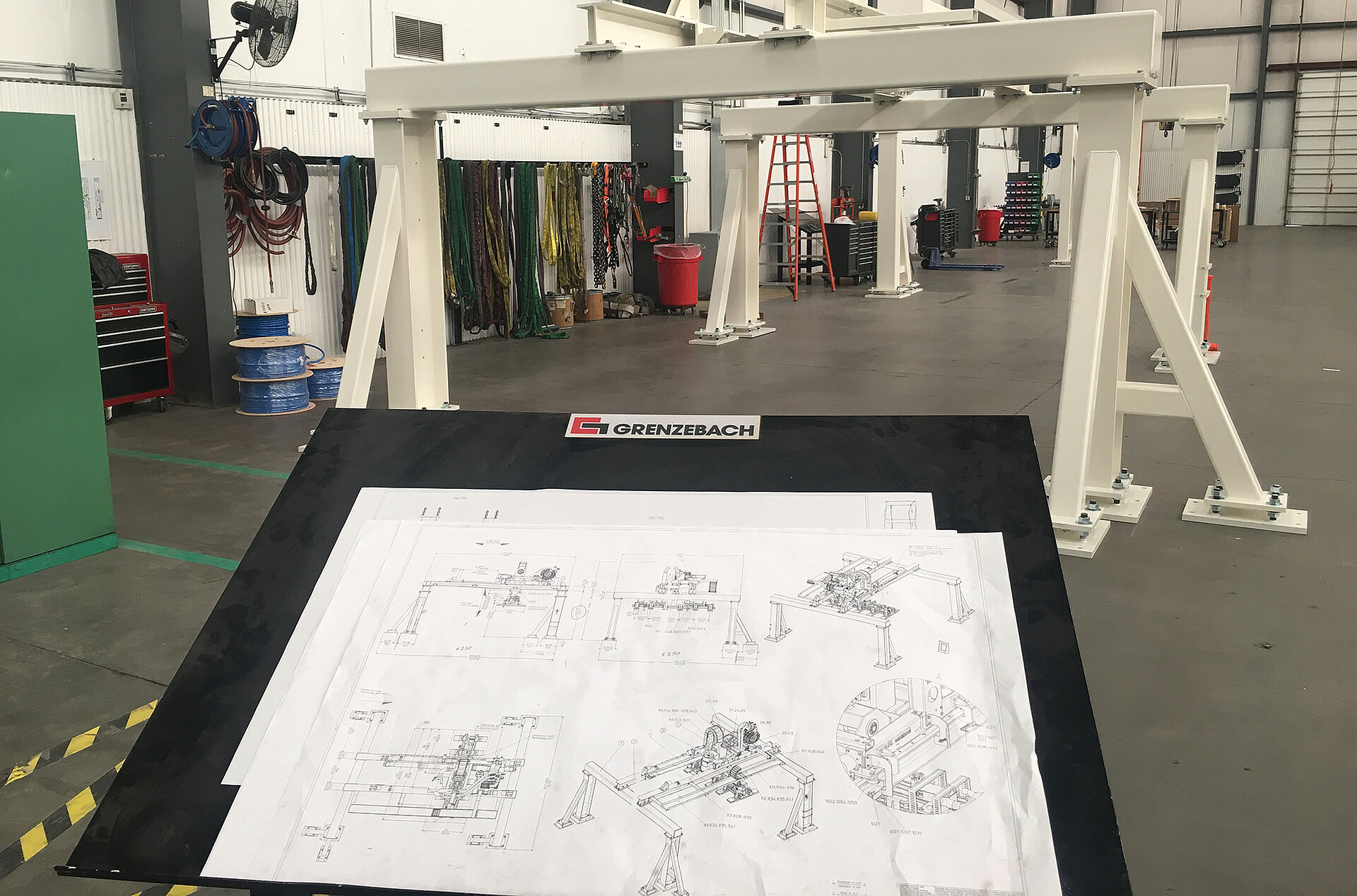

Whether a single part or a full system Grenzebach understands the value each project has to our clients. At Grenzebach we treat every build-to-print solution as if it was our own design. Helping our partners by not only manufacturing the design they provide, but by also offering solutions to make it better when applicable.

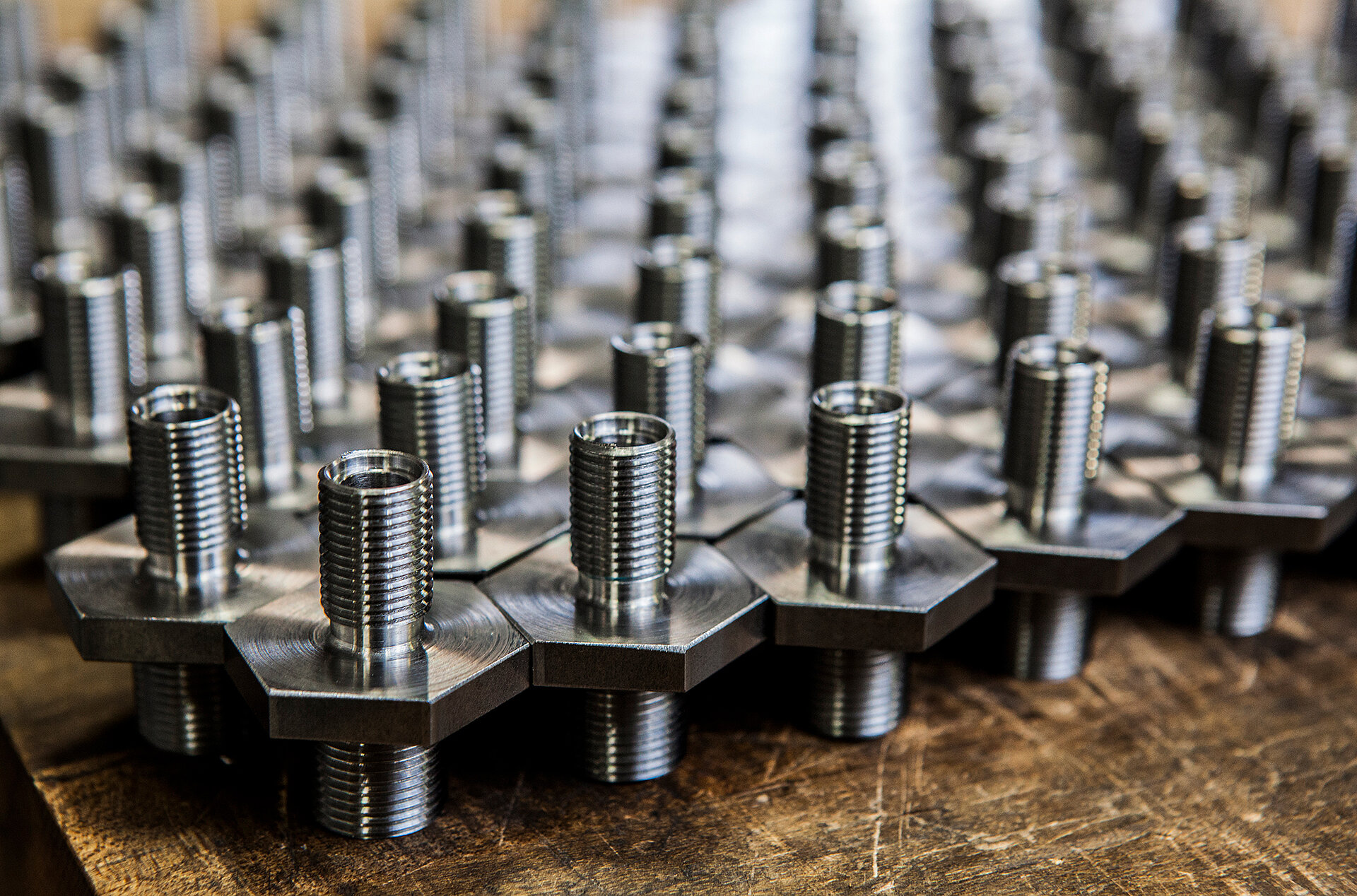

There are many reasons why you can reliably outsource the production of complete components or entire machines to Grenzebach. For decades, we have stood for outstanding quality of assemblies, components and machines in contract manufacturing. We manufacture with the highest precision so that you can use or further process them perfectly.

Even if you are at the very beginning of a series, we are at your disposal with our sound knowledge and many years of expertise.

At the Newnan (USA) site, Grenzebach has been offering the latest production technology since 1988 with currently over 90 employees and more than 120,000 ft. sqr. of production space. Thus Grenzebach is successfully active as a certified system supplier for the industry.

The demanding customers from various industries have the highest requirements regarding quality and performance.