Component handling fast and safe

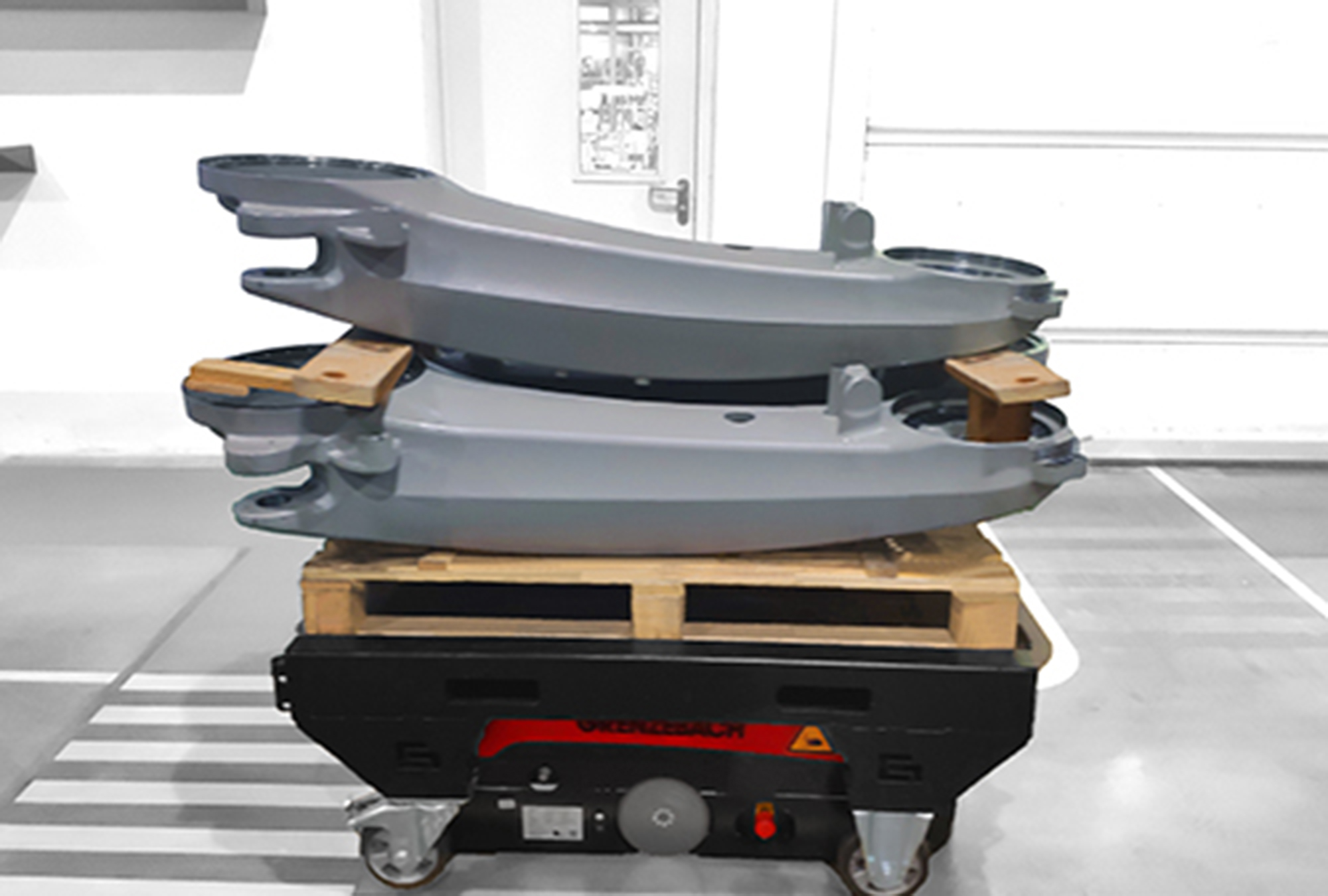

Casting parts moving through the Grenzebach workshops in Jiashan near Shanghai: L1200S, Automated Guided Vehicles (AGV) that are manufactured in-house, transport components from the machines directly to the measuring station in the quality assurance lab and the goods leaving inspection before packaging. The assistance of employees and long transport routes with heavy casting parts are no longer required. “With the automated transport we are able to work even more efficiently in the casting part sector. Together with the new logistics execution system we present our ideal solution for a Smart Factory”, says Alfred Schlosser, CEO from Grenzebach Jiashan. In the workshop, the two L1200S transport work pieces between a total of 7 AGV stations with 29 parking locations. The Grenzebach fleet manager ensures an optimized continuous material flow.

Goods carriers as manual carts

The L1200S move casting parts with 20 goods carriers developed and built by Grenzebach: These can be automatically moved with an Automated Guided Vehicle, at the same time they can be used as manual carts. “The manual carts keep everything moving even when one of the L1200S needs servicing. This option is available to customers who will use the newly conceived goods carriers”, says Alfred Schlosser.

Highest personal security

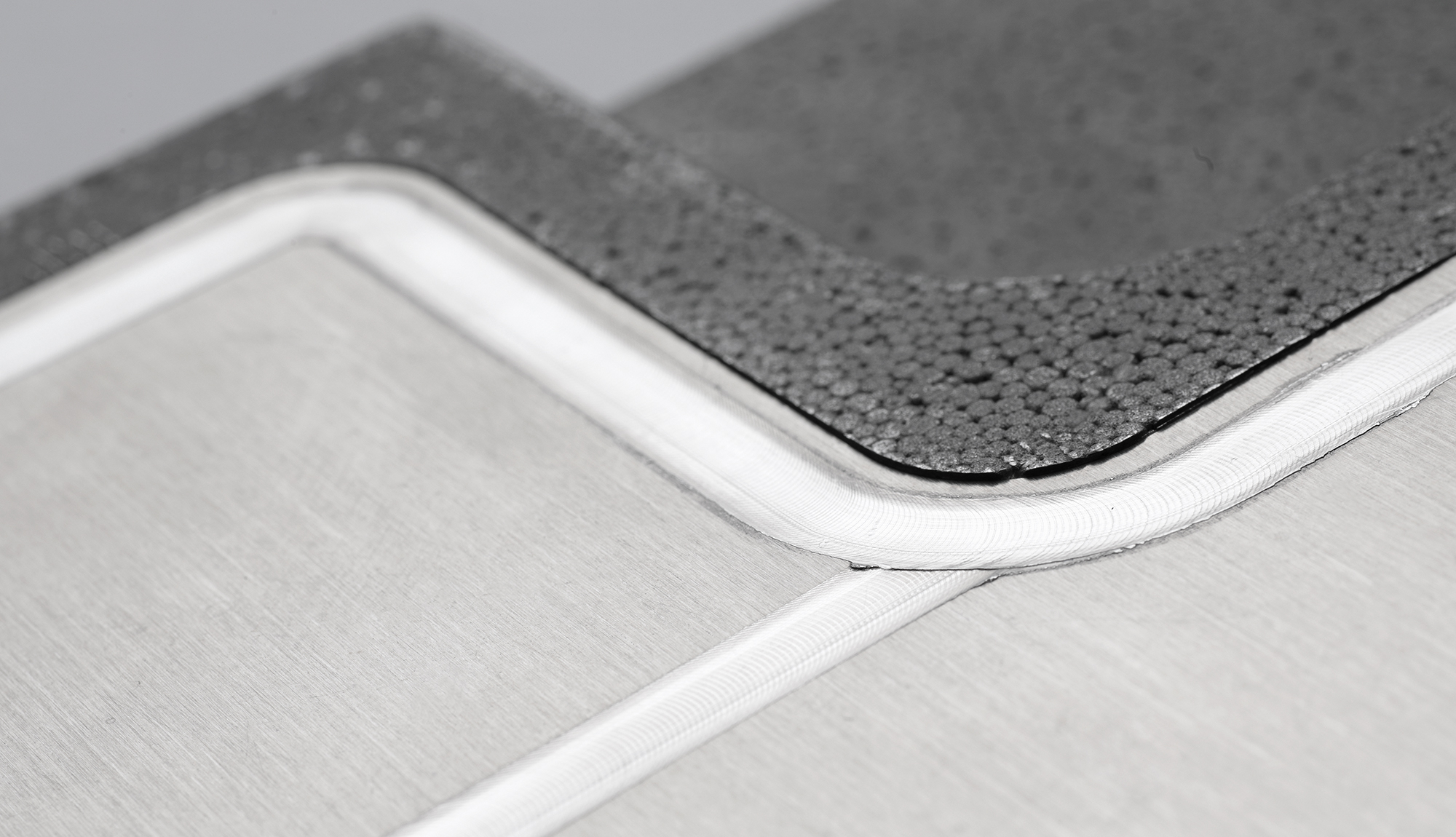

Like the colleagues in the Bavarian Hamlar, employees in the Chinese Jiashan take full advantage of the benefits of the L1200S: With tablets at the stations, the AGVs can be navigated and with the large screen display current locations are always visible. With an integrated staff safety sensor technology and free shape navigation, the L1200S can be used flexibly and protective areas are not necessary. New energy is supplied to the AGVs in an uncomplicated manner with contactless inductive charging on special mats.

Casting components on their way from the mechanical processing to the quality assurance: The workshop gates automatically open for the L1200S and close again after their passage. The AGVs are integrated into the fire detection system - and will immediately release the access roads in the case of a fire.

Up to 1.2 tons in length or cross direction

Priority for flexibility: Occasionally the L1200S transport heavy work pieces. The vehicles can transport loads of up to 1.2 tons in length- or crosswise direction. They can rotate on the spot and travel with speeds of up to one meter per second.

Free travel to the Future

The next step is already being planned for. At the end of this year, the AGVs in Jiashan shall also carry out the overall transport of waste chips from the CNC center, at least twenty tons of various metallic granulates per month, day in and day out.