Grenzebach: Future-Oriented Automation Specialist

Thinking Ahead Markets and Products

Do you want to enhance the efficiency and productivity of your processes? You came to the right place because the world of industrial automation is Grenzebach’s home.

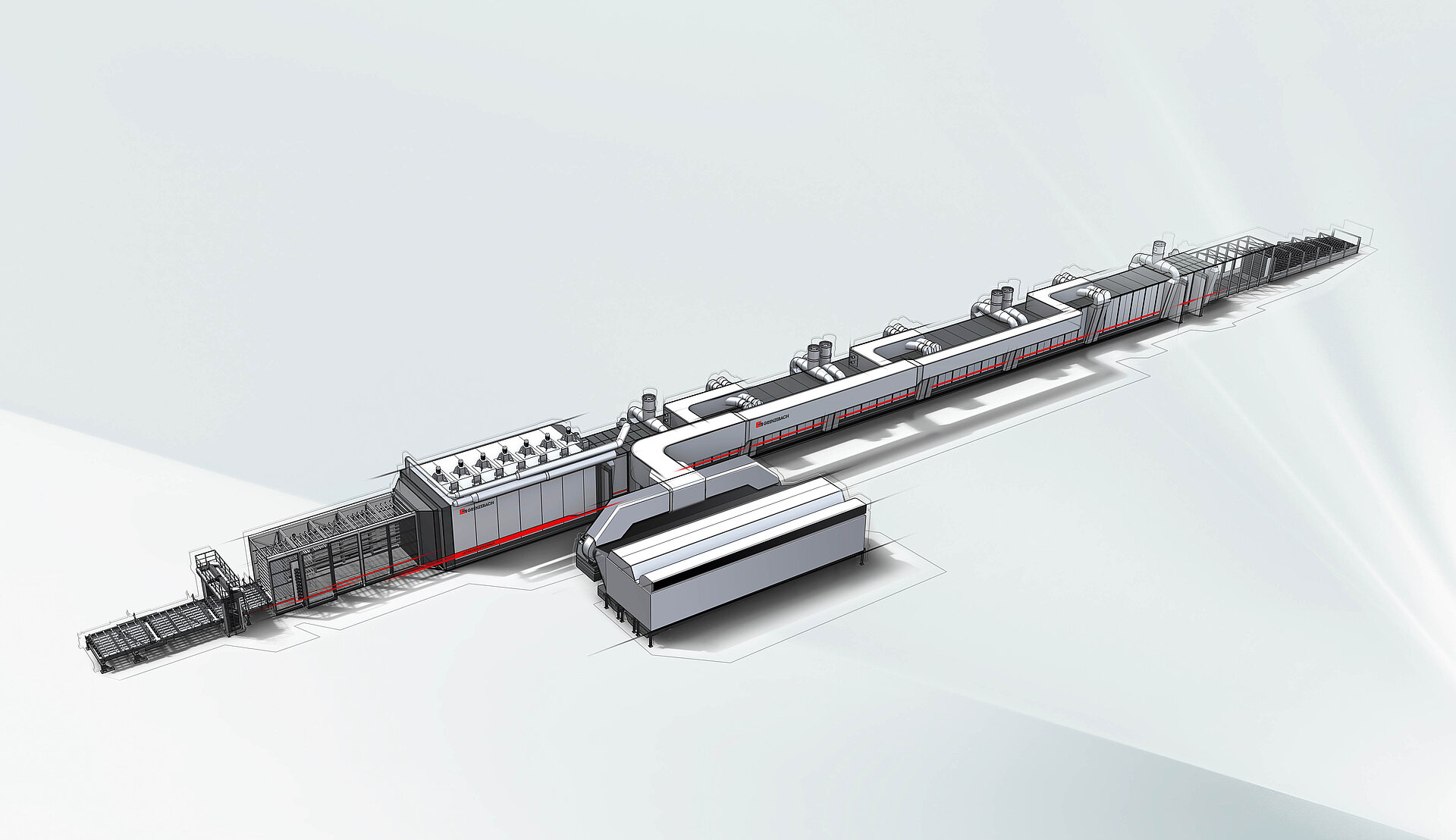

We provide industrial automation solutions for global glass and building materials markets. Furthermore, Grenzebach is active in other business areas, including casting, intralogistics, various recycling processes, friction stir welding, the automation of industrial additive manufacturing, digital networking, power & energy, and solutions for processing bulk solids and powders

employees do their utmost every day to ensure your success.

years of experience are the foundation on which we build our innovations for tomorrow’s markets.

manufacturing and development sites—complemented by a global sales and service network.

What Our Customers Say

Worldwide Contact

Grenzebach Group worldwide

By loading the map, you agree to Google's statement of privacy protection.

Here you can find out more what this means for the protection of your personal data.

Contact us any time

We're Happy to Help You!

Collaboration means dialogue. We support you no matter where you are in the world. Contact us. Send us your inquiries. We're looking forward to hearing your ideas.