Driving the horizontal and vertical energy transition in Europe and the world

In many countries, the focus of politics, business, and society is on the rapid and vigorous expansion of renewable energies. The goals for renewable energy are ambitious and the global political situation is also speeding up the process of becoming independent of fossil fuels. The sun has a special role in the energy mix, being the most powerful energy source of all. Photovoltaics generate electricity; solar thermal heat.

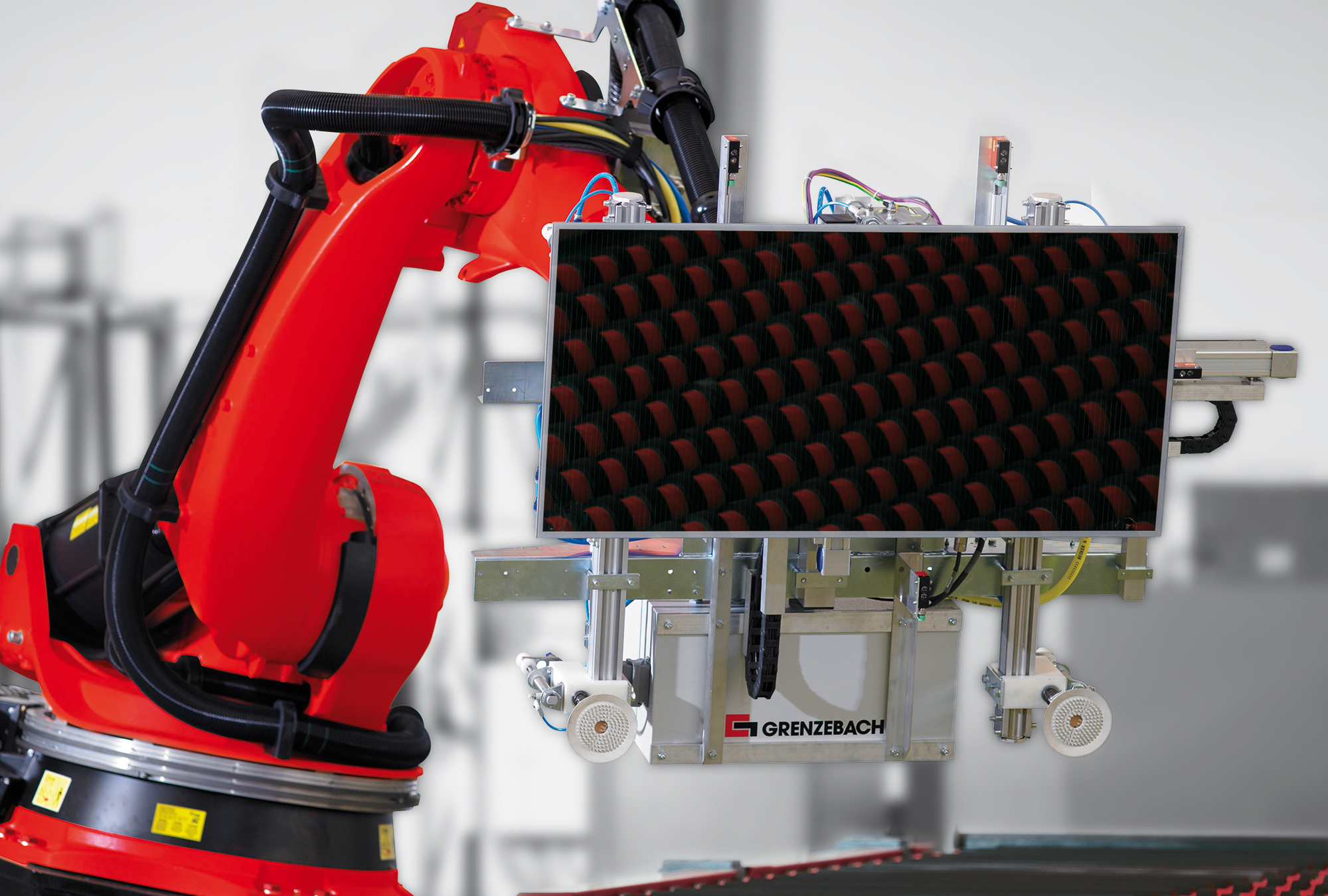

For years, Grenzebach has been putting a lot of innovative energy into production technologies that harness the power of the sun. Production lines for manufacturing patterned glass

Technology for thin-film solar modules

CUSTOMIZED FRONT END AND BACK END

Worldwide, more than 40 Grenzebach thin film lines have been installed for CIGS and CdTe technologies. Our portfolio ranges from conveyance and buffering technology to in-house developed MES systems.

Front end

The front end of the line produces the substrate. In addition to tracking the substrate ID, the temperature and cleanroom parameters are monitored. Our state-of-the-art inspection systems ensure a high-quality standard. Storage systems for interim buffering at the coating and structuring processes increase the overall throughput through the front end.

Back end

In the back end of line, the module is produced from the individual substrates. Laser edge deletion, film unwinding, pairing, film trimming and J-Box installation are key processes of our back end. Tailored back rail applications, as well as packaging and warehouse systems, complete our back end product range.

For North America

Your contact person: Ron LaBorde

You would like to know what Grenzebach glass solutions can do for you? Call or write us about your challenge. We look forward to hearing from you!

For Europe, Asia, South America and Pacific

Your contact person: Markus Gruber

We are your sparring partner, offering digital solutions with a vision In this way, you can maximize the added value of your system.