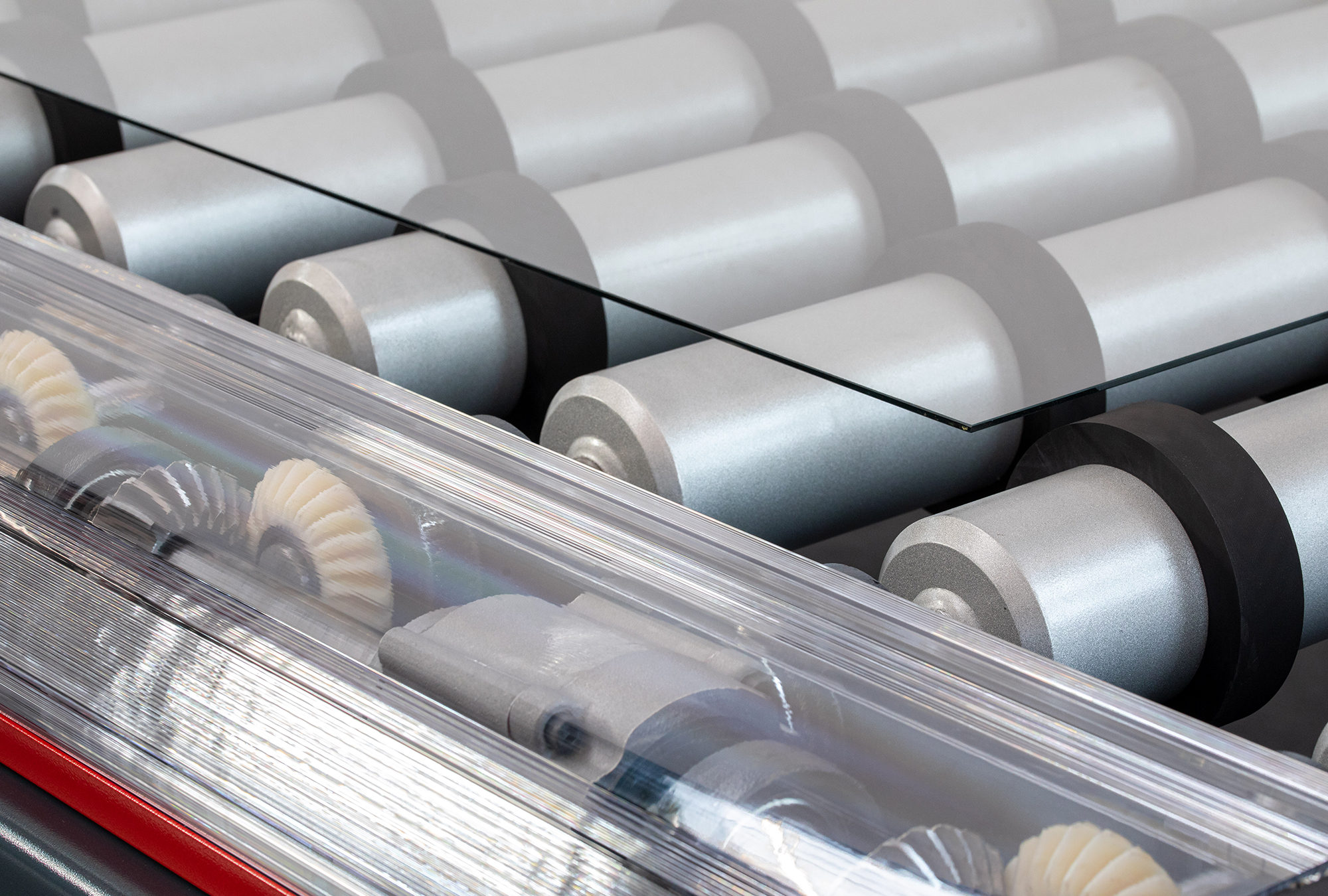

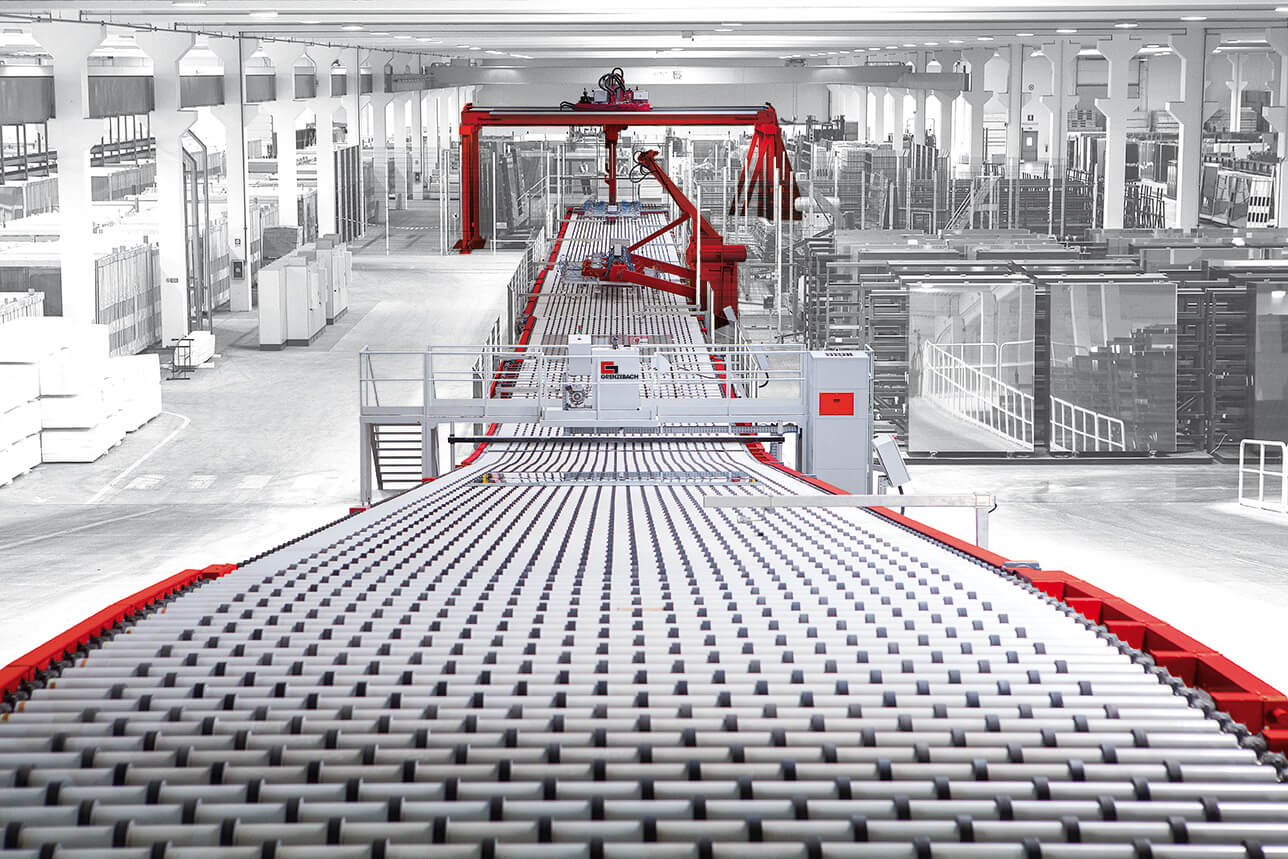

Grenzebach offers best-in-class technologies to guarantee precise stacking at the end of the glass lines:

- Sheets of glass can be simply removed by hand or by using a fully automatic stacker

- for small, mid-size, large and extra-extra-large glass sheets of up to 24 meters or 26 yards

- and weighing up to 3 tons or 6613 pounds.

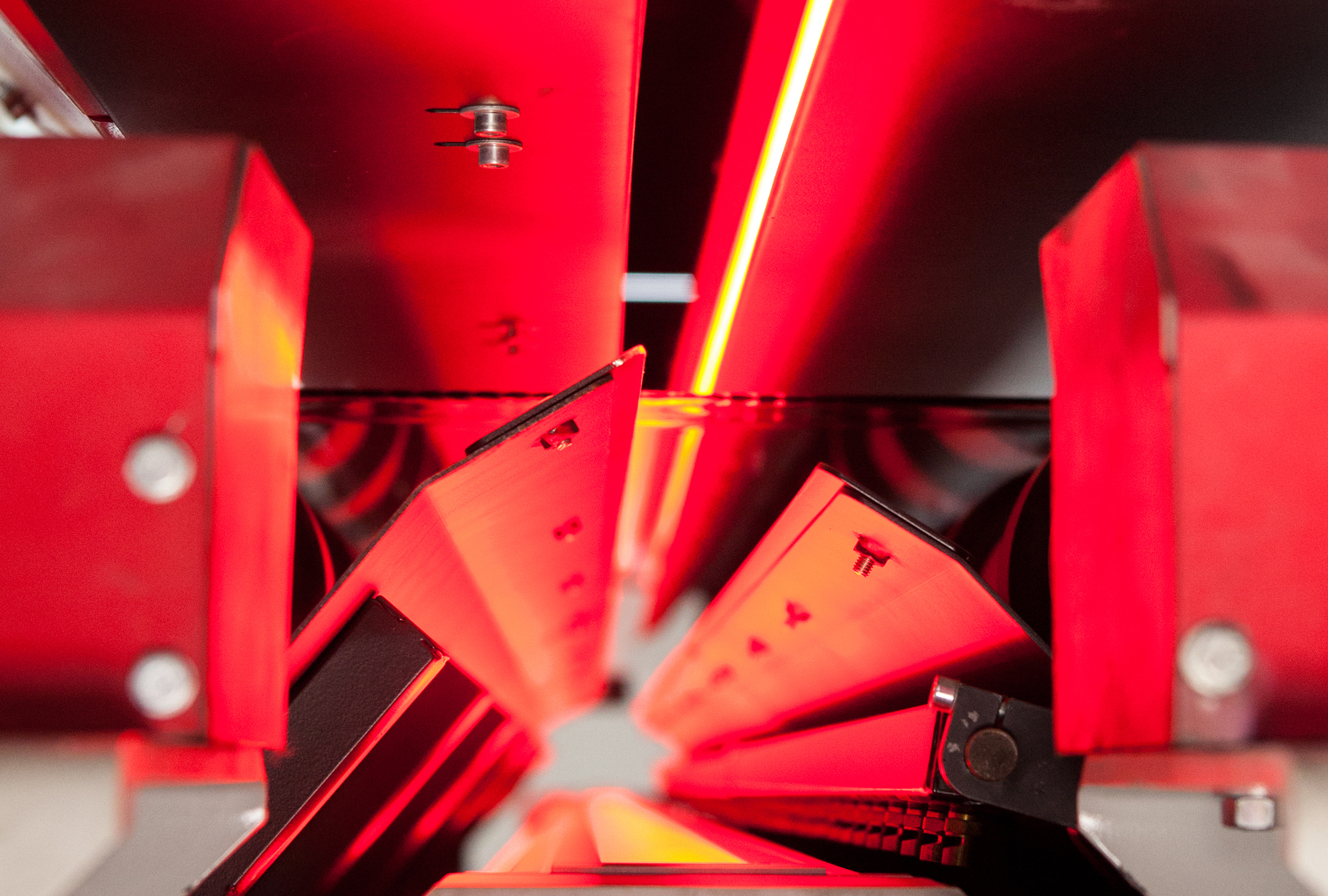

The sheets of glass can be removed from the tin or air side, from several levels – tiers and drops, statically or picked on the fly. Single or dual pick options ensure greater efficiency. The smart combination of two stackers, which can be used singly or as a pair for extra-long sheets, allows fully flexible production.

“We can develop a smart system for you so that conveying and stacking are a class act. What’s required is the right number of stackers at maximum capacity to deliver a highly accurate and scratch-free result.”

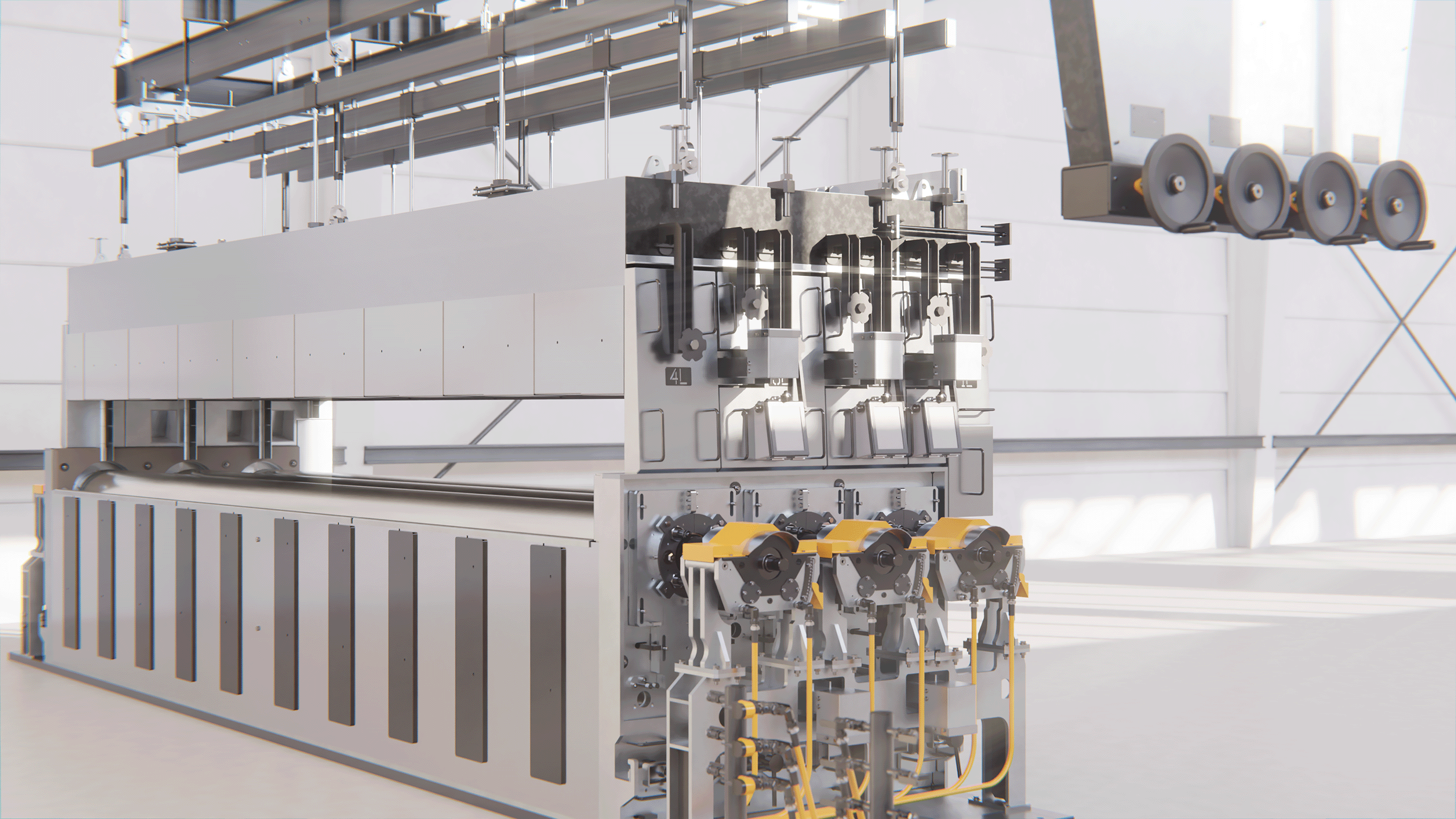

Grenzebach handling equipment

The Grenzebach portfolio has a large variety of handling equipment, ranging from

- portal stackers,

- swing stackers,

- direct stackers,

- under-table stackers

- and robot technology.

Various combinations of handling equipment and platforms are possible, too. And it’s all adapted to cope with the subsequent material flow.

For North America

Your contact person: Ron LaBorde

You would like to know what Grenzebach glass solutions can do for you? Call or write us about your challenge. We look forward to hearing from you!

For all other regions

Your contact person: Florian Nagler

Collaboration means dialogue. We support you no matter where you are in the world. Contact us. Send us your enquiry.