Utilize Potential Across Trades!

DIGITALIZATION

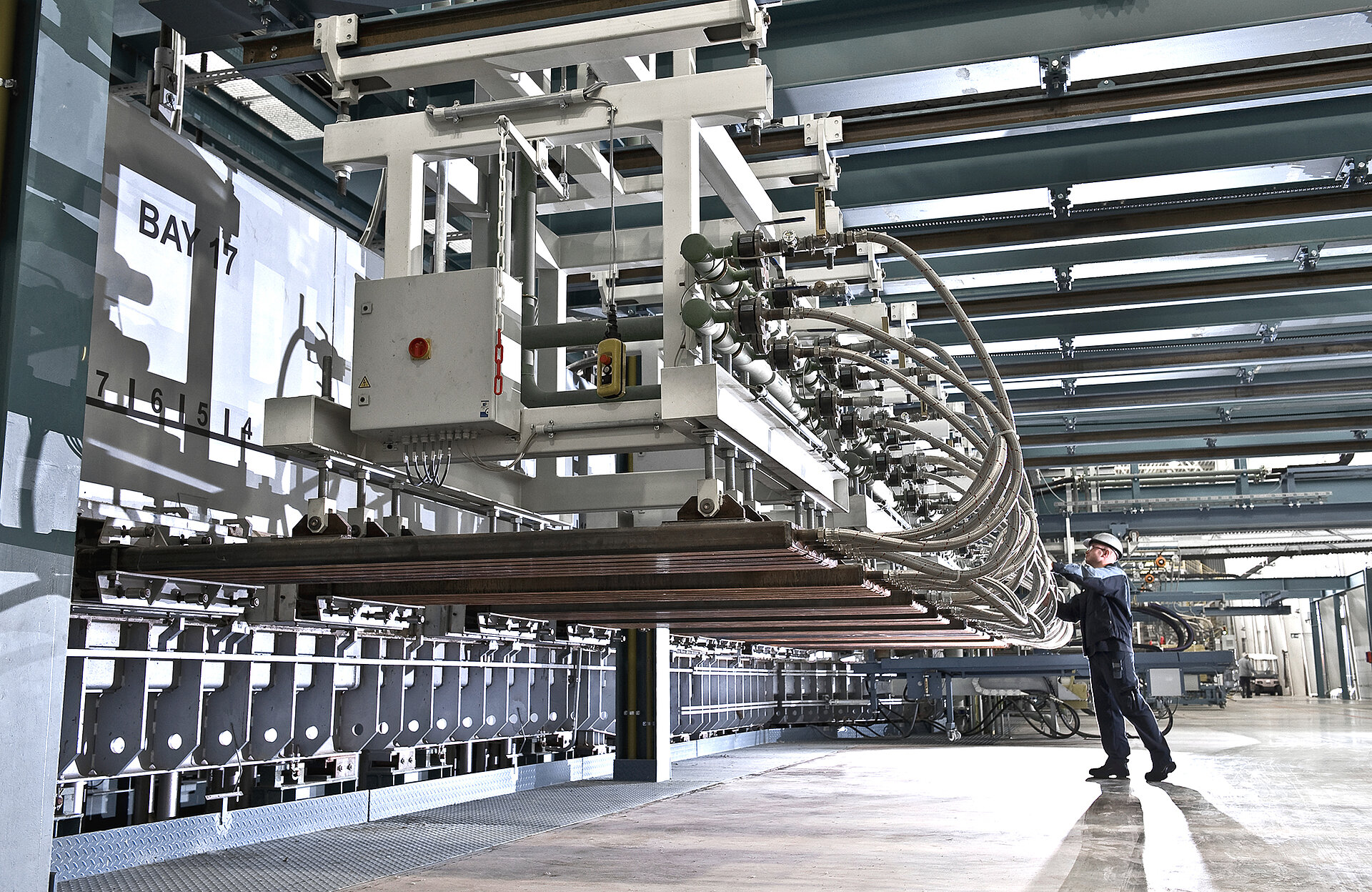

From the hot end to the cold end, digitalization allows you to optimize your value-added processes and connect previously separate trades. Utilize the enormous potential of digitalization to increase your existing quality and efficiency further. Thanks to the intelligent networking of individual trades and data-based software solutions, you can collect a vast amount of data along your glass line. Valid value is created by bundling and analyzing information and deriving optimizations. This allows you to create an intelligent ecosystem in which the competitive glass production of tomorrow is possible.

The digital solutions of our software landscape SERICY network and analyze information using intelligent AI. You will receive apps, for example, for process monitoring and system control, and create immediate added value. We provide that the digitalization of your glass production plant is as simple as possible.

Digital Solutions With Practical Value

Creating Transparency

Software solutions visualize production and machine data and make it available at all times. You can read, process, and analyze previously unused, valuable data at the field level with our SERICY solutions. You and your employees gain more profund insights for better decisions.

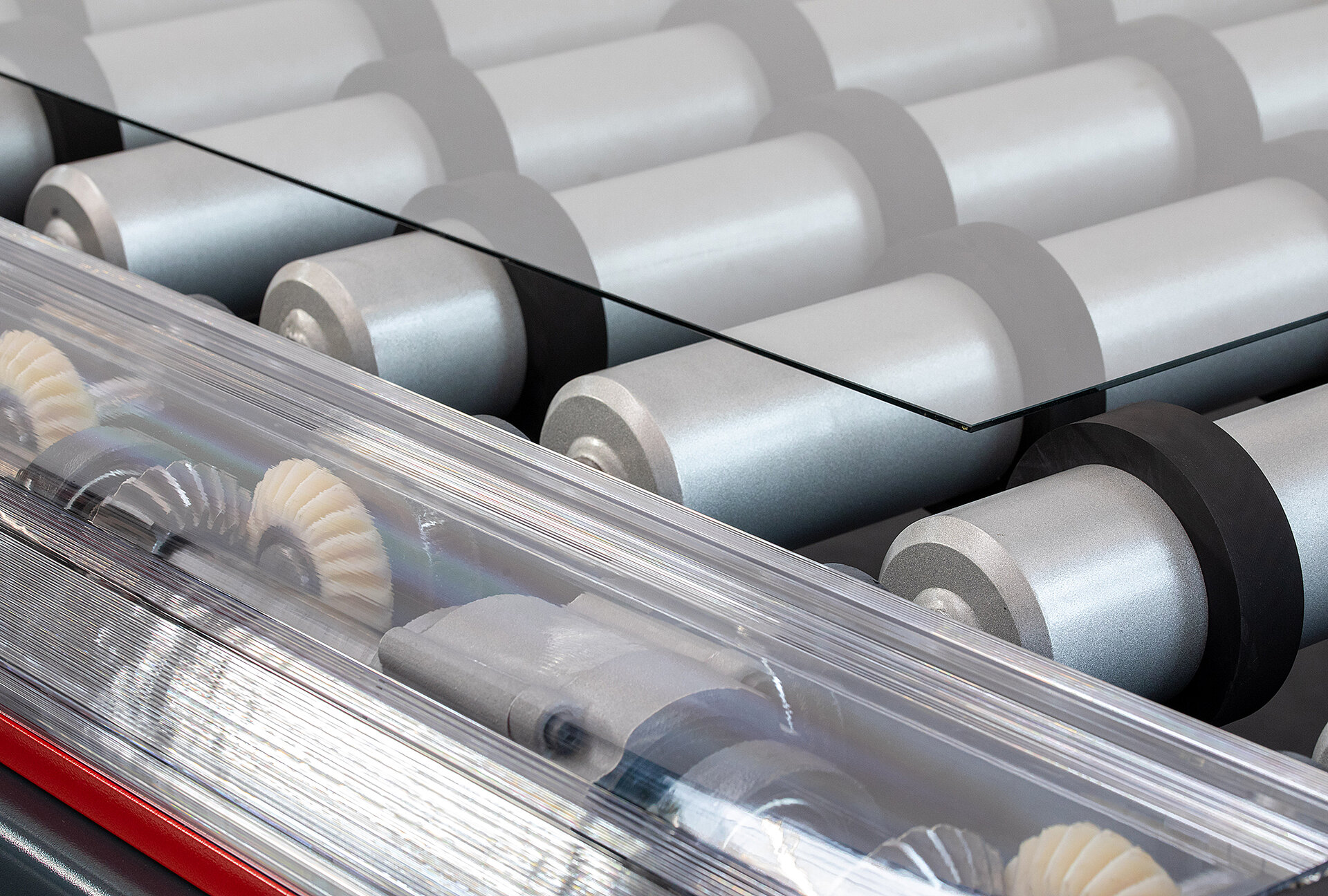

Increasing Product Quality

The SERICY apps transform raw data into valuable information. This knowledge flows directly into the production process or is used for special tasks. Based on the analyzed data, proactive recommendations can be derived to optimize the machine settings so that you can continuously produce high-quality glass

Increasing Yield

You can lower your production cost with the digital solutions of the SERICY ecosystem. Monitoring systems function as an early warning system to prevent or shorten downtimes. Monitoring and reporting tools simply and intuitively visualize your production process so that you can optimize it to the maximum.

“Digitalization is transforming traditional value chains into networked ecosystems in glass production. An exciting time! SERICY is the core of an intelligent workflow that makes production and machine data always available. The basis to improve digital glass production every day.”

Welcome to the SERICY Ecosystem for the Glass Industry

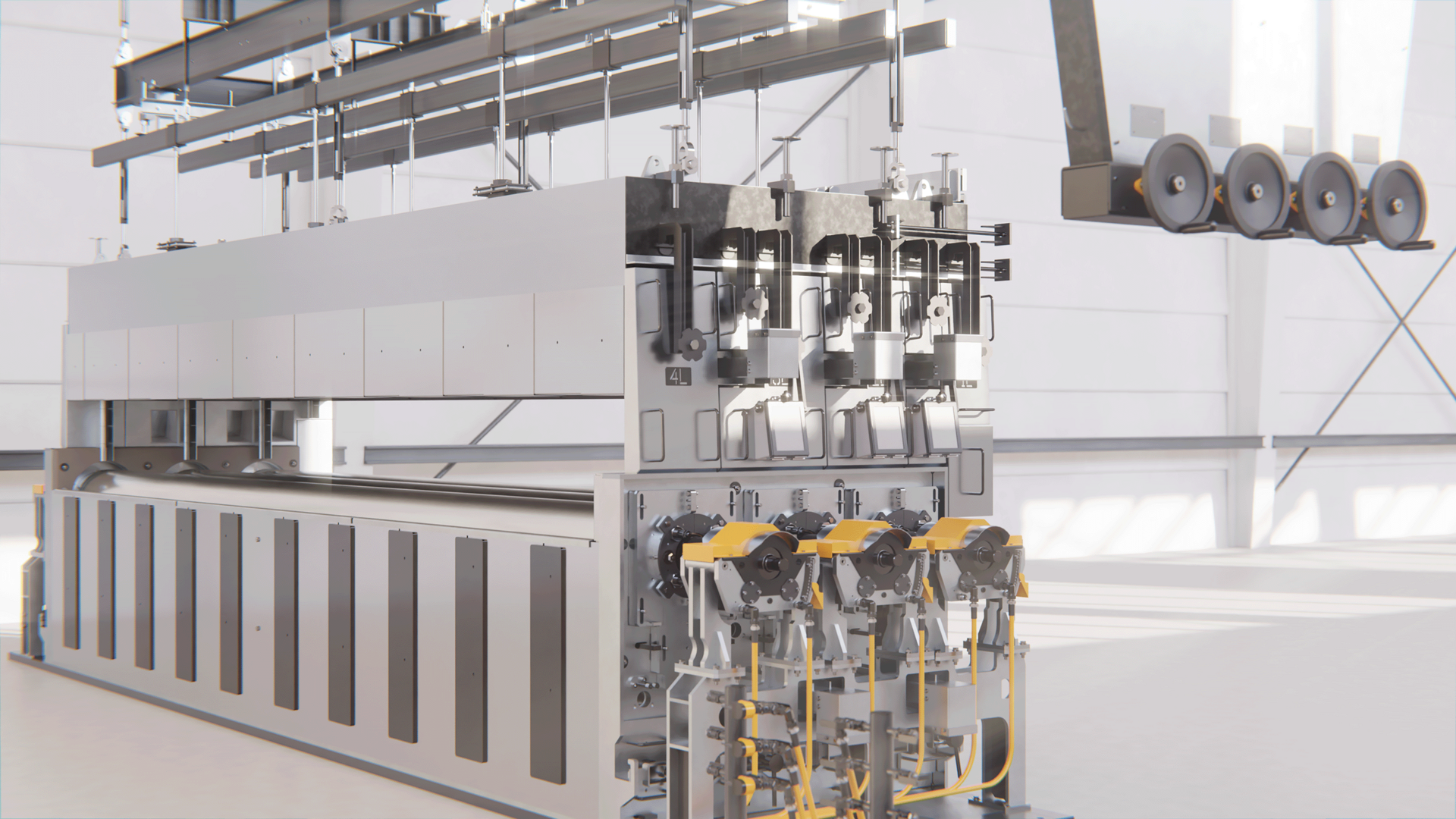

Grenzebach's SERICY software landscape makes your glass production fit for the future. Pick and choose the SERICY applications that best support you in your challenge. Interfaces to all lower and higher-level systems ensure system transparency, a fundamental prerequisite for added value in digitalization.

Due to our intelligent data management, optimum integration is achieved from the field level via the control and management system to ERP systems and other SERICY solutions with machine learning and analytics applications.

With Our Operating Concept, You Can Precisely Visualize the Information You Need:

Regarding technology, product traceability is based on a product ID to which all information, such as size, production date, or production steps, is attached. The physical product is labeled with one of the following technologies, depending on the area of application:

- Barcode printing

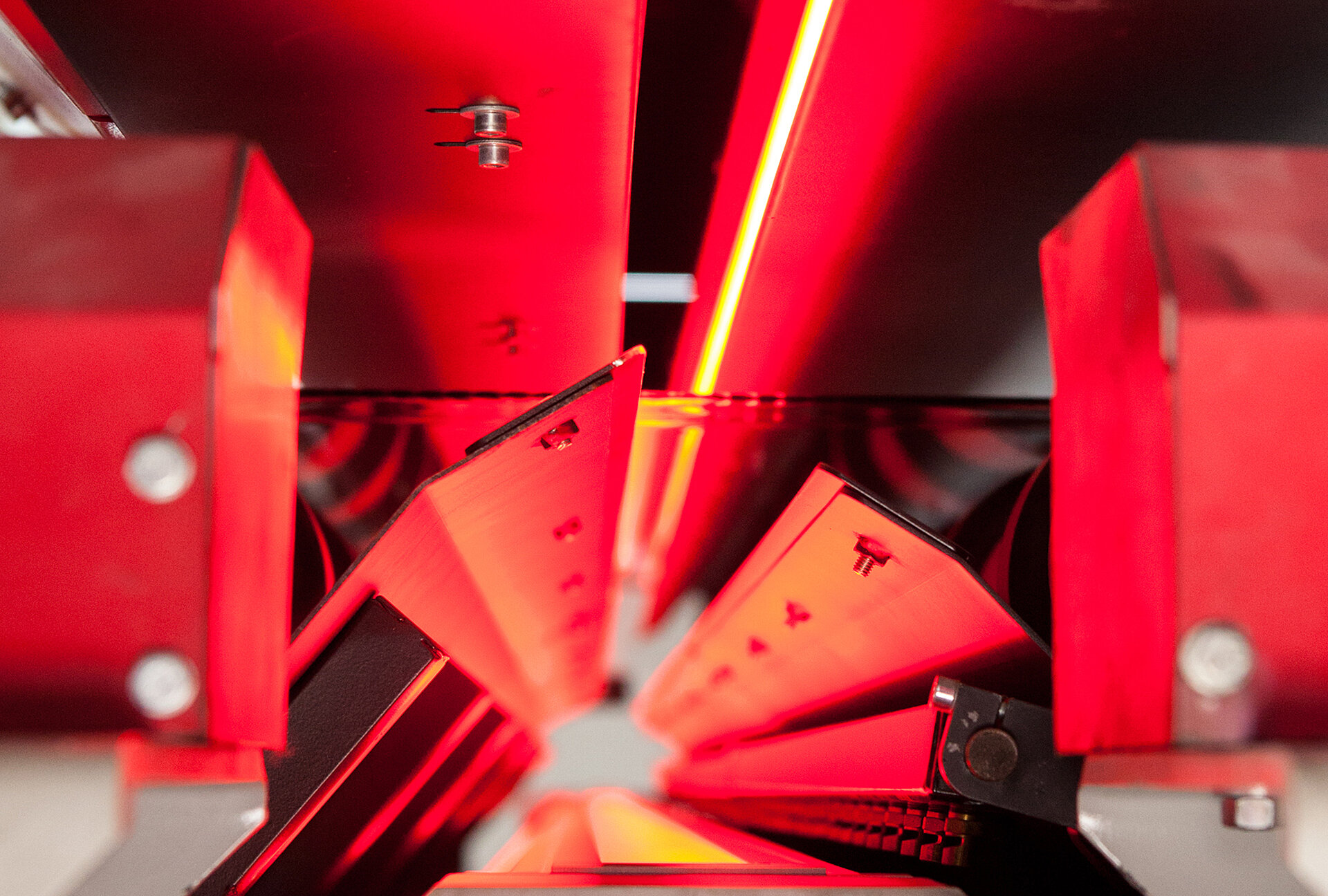

- Laser engraving, for example, QR code

- Labeling: Applying labels

- RFID-Tag (Radio Frequency Identification) and contactless reading via radio frequencies

For North America

Your Contact Person: Ron LaBorde

You would like to know what Grenzebach glass solutions can do for you? Call or write us about your challenge. We look forward to hearing from you!

For Europe, Asia, South America and Pacific

Your Contact Person: Markus Gruber

We are your sparring partner, offering digital solutions with a vision In this way, you can maximize the added value of your system.