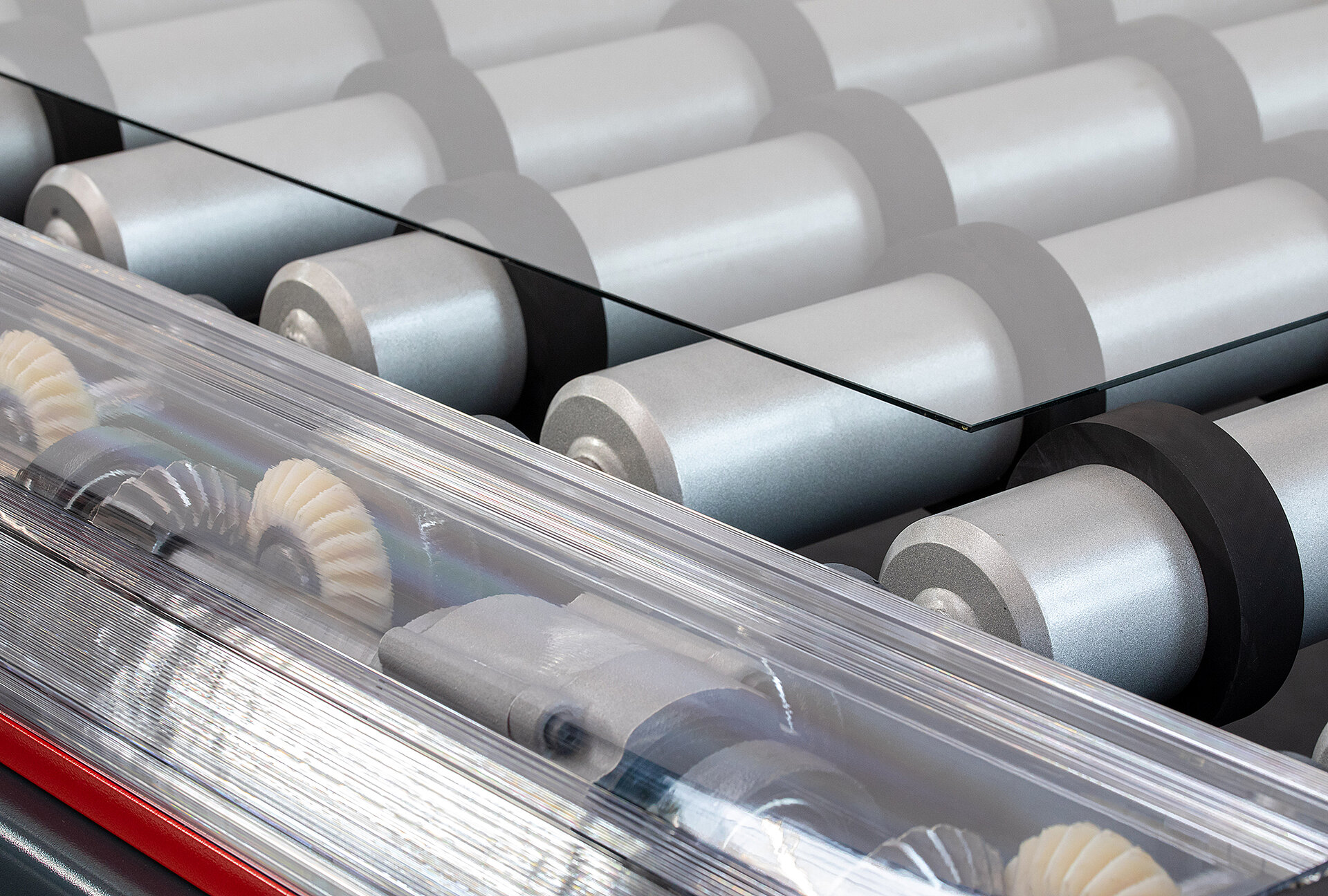

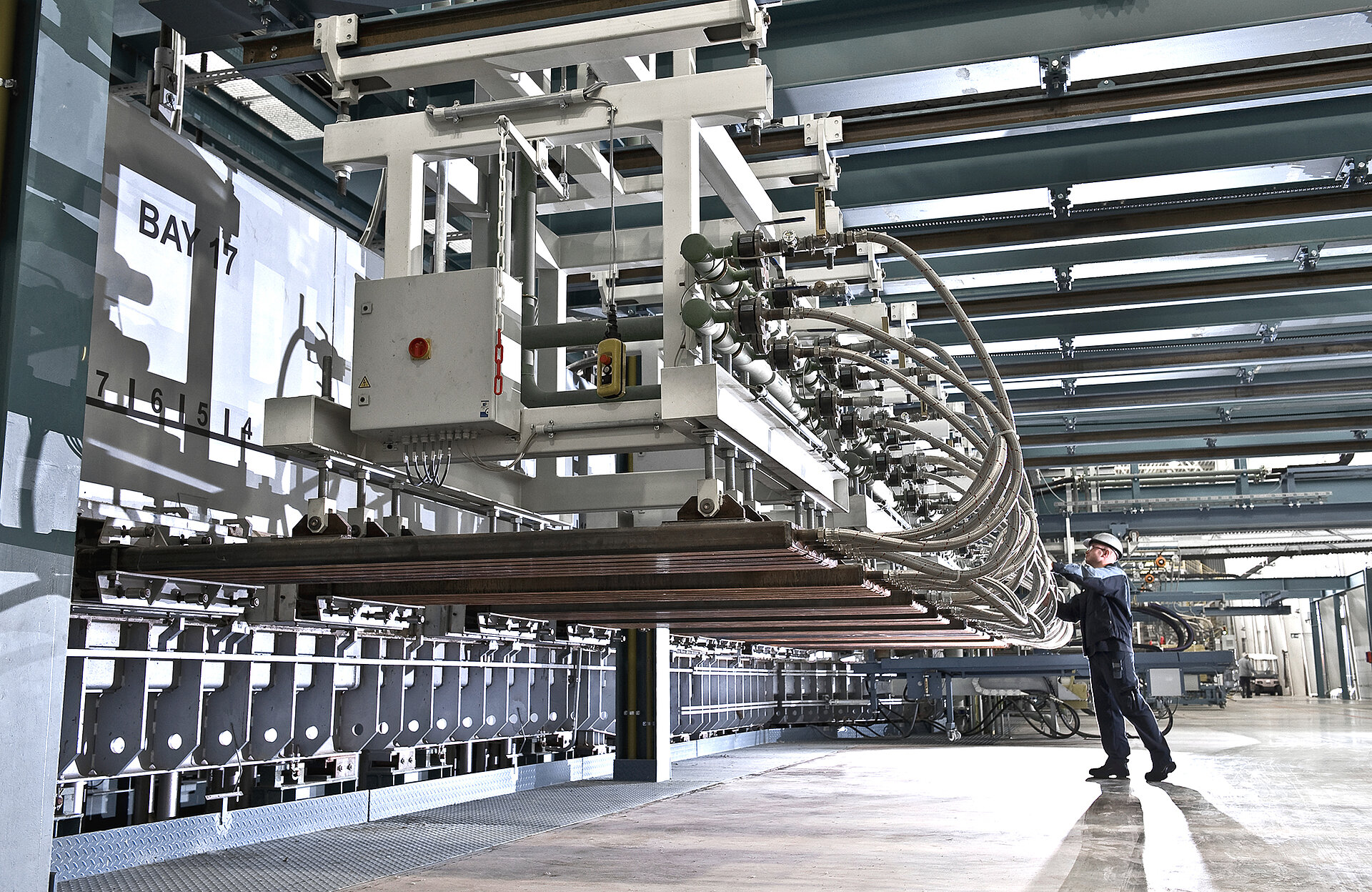

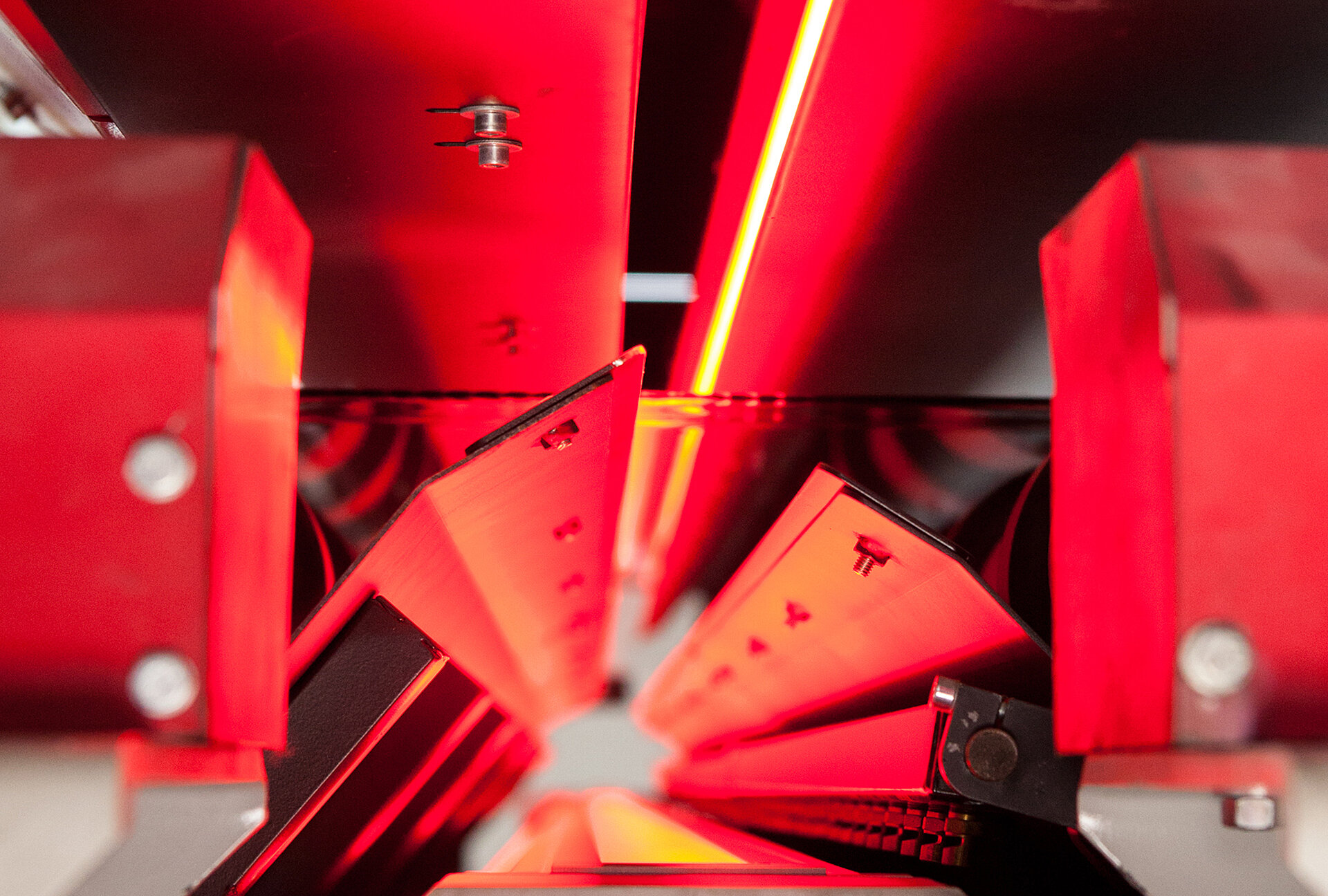

Our Technology Conveys Glass Gently and Precisely – Even Over Distances Greater Than 100 Meters or 110 Yards. Furthermore, Our Conveying Solutions Operate Smoothly and Have Long Service Lives Too.

- Conveying systems with specific functions

- Robust, durable, efficient, low on maintenance and emissions

- Ideal, steady material flows

We also have experience with providing tailor-made solutions, such as cleaning devices, or handling customized glass widths of up to six meters or approx. 19.7 foot. We’ll do everything needed to ensure glass is conveyed without any scratches or residues left behind.

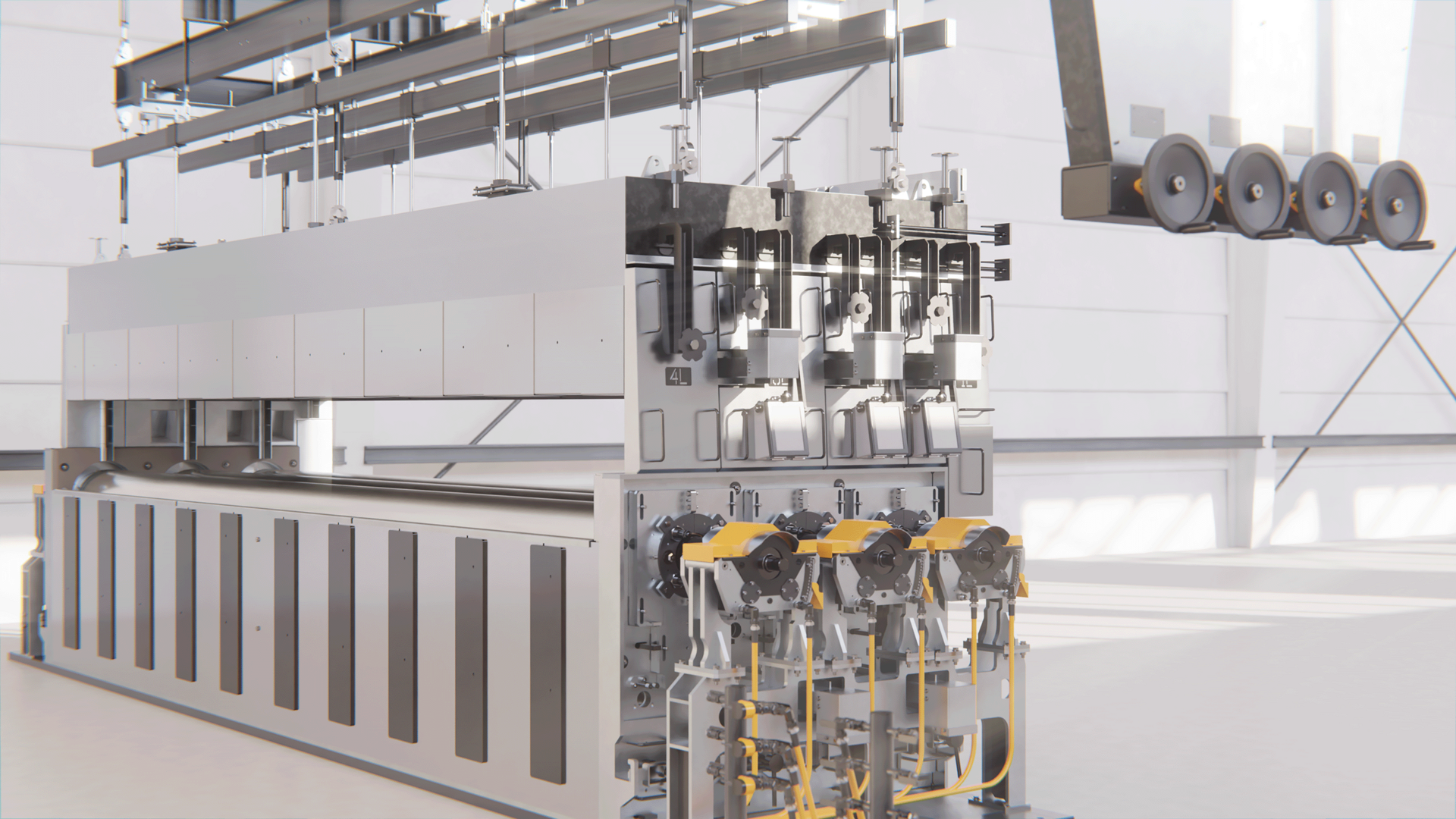

Conveying Technology: Even More Dynamic, Even More Robust

New generation

Transporting glass gently, carefully and safely has always been one of Grenzebach's top priorities.

The specially developed drive train without cardan shafts represents a major step forward. The number of components in the drive has been significantly reduced - cardan shafts and belts are a thing of the past. This now results in even greater dynamics, less maintenance work and a lower spare parts inventory. The new drive train also offers the possibility of connecting all engines directly, which ensures smoother running and higher positioning accuracy. Gentle glass transport all along the line!

Thanks to its new design, compact construction and transparent covers, the new conveyor technology generation also provides a clear view of key components and fast access for maintenance work. Of course, existing systems can be equipped with the new conveyor technology so that everyone can benefit from the advantages.

“The most important thing for us has always been to transport glass gently and safely through the cutting and stacking processes in order to help you achieve the maximum yields. We have taken a big step into the future with our next generation of conveyors.”

For North America

Your Contact Person: Ron LaBorde

You would like to know what Grenzebach glass solutions can do for you? Call or write us about your challenge. We look forward to hearing from you!

For all other regions

Your Contact Person: Florian Nagler

Collaboration means dialogue. We support you no matter where you are in the world. Contact us. Send us your enquiry.