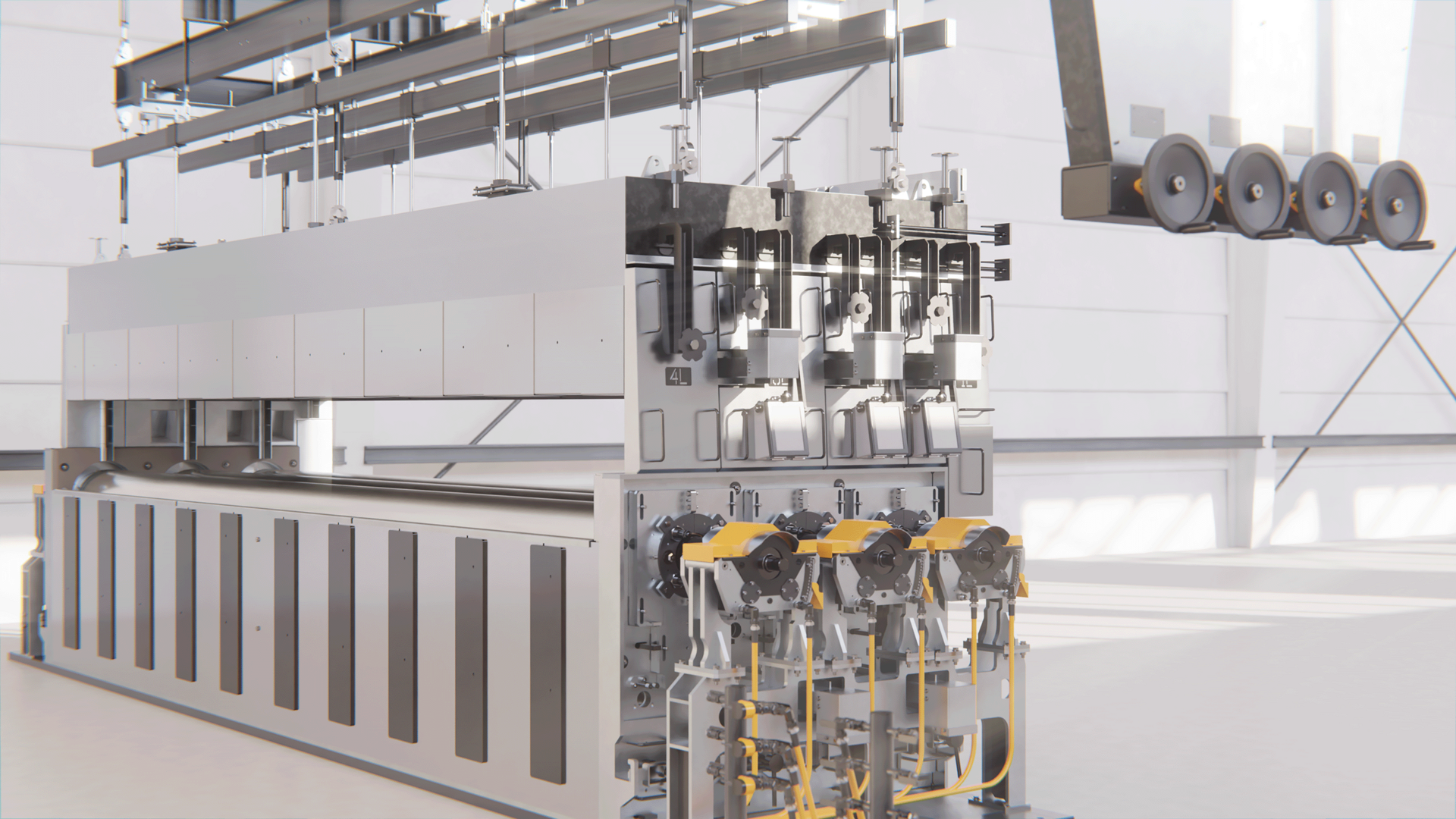

In the dross box, the glass floating on the tin is lifted out of it for the first time and transferred to the annealing lehr. The trick is to transfer the glass ribbon from a liquid and full-surface support to a roller conveyor. The dross box also has the important task of sealing the tin bath atmospherically.

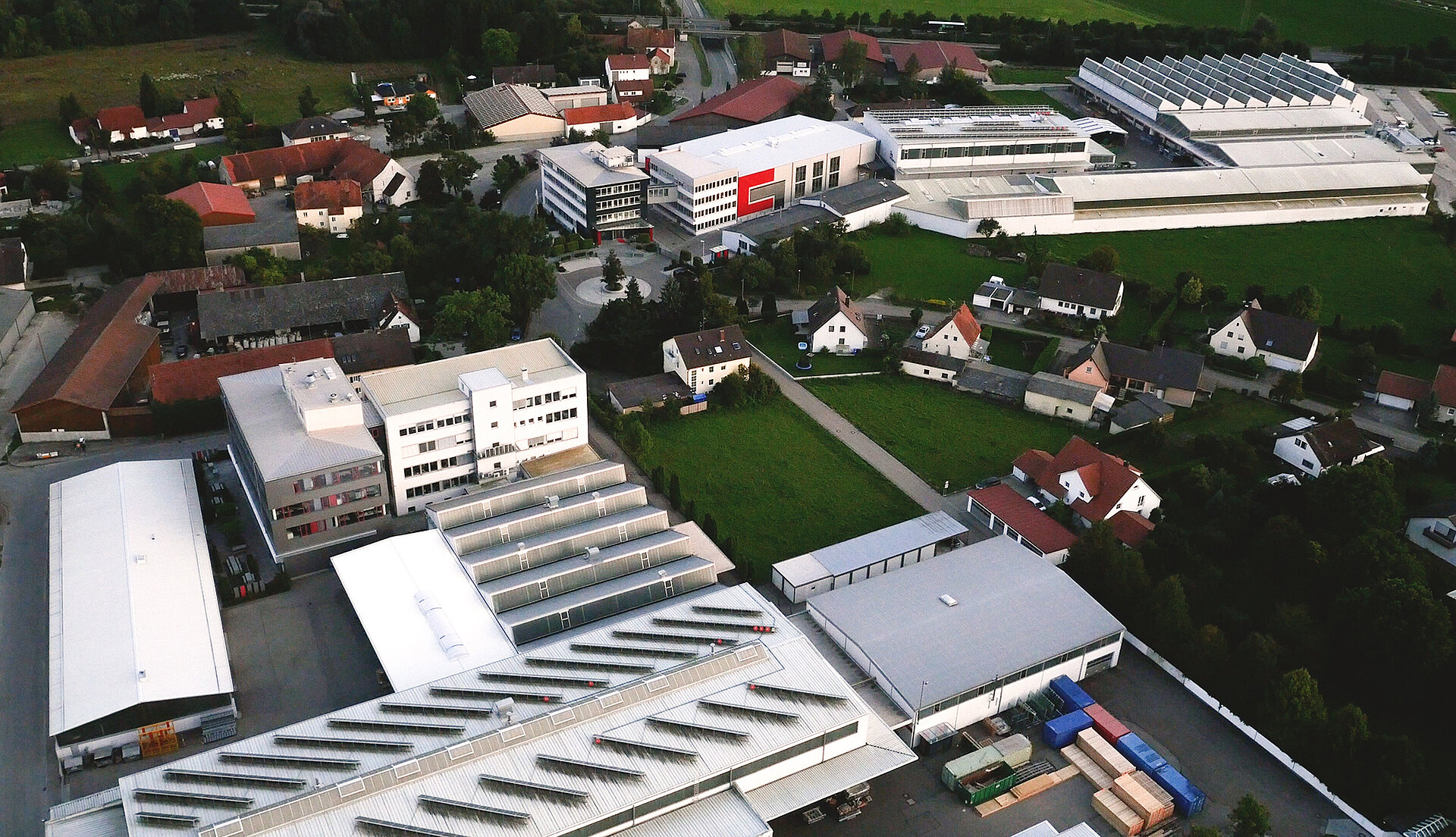

In the dross box, the glass ribbon is in a sort of transition phase from tin bath to annealing lehr. It is already in a viscous, "doughy" state here, but still has high temperatures around 600°C. With years of experience, Grenzebach develops optimally designed systems for each production step. This creates a fascinating, high-quality material for countless objects in our everyday lives. In the dross box, the glass floating on the tin is lifted out of it for the first time and transferred to the annealing lehr.

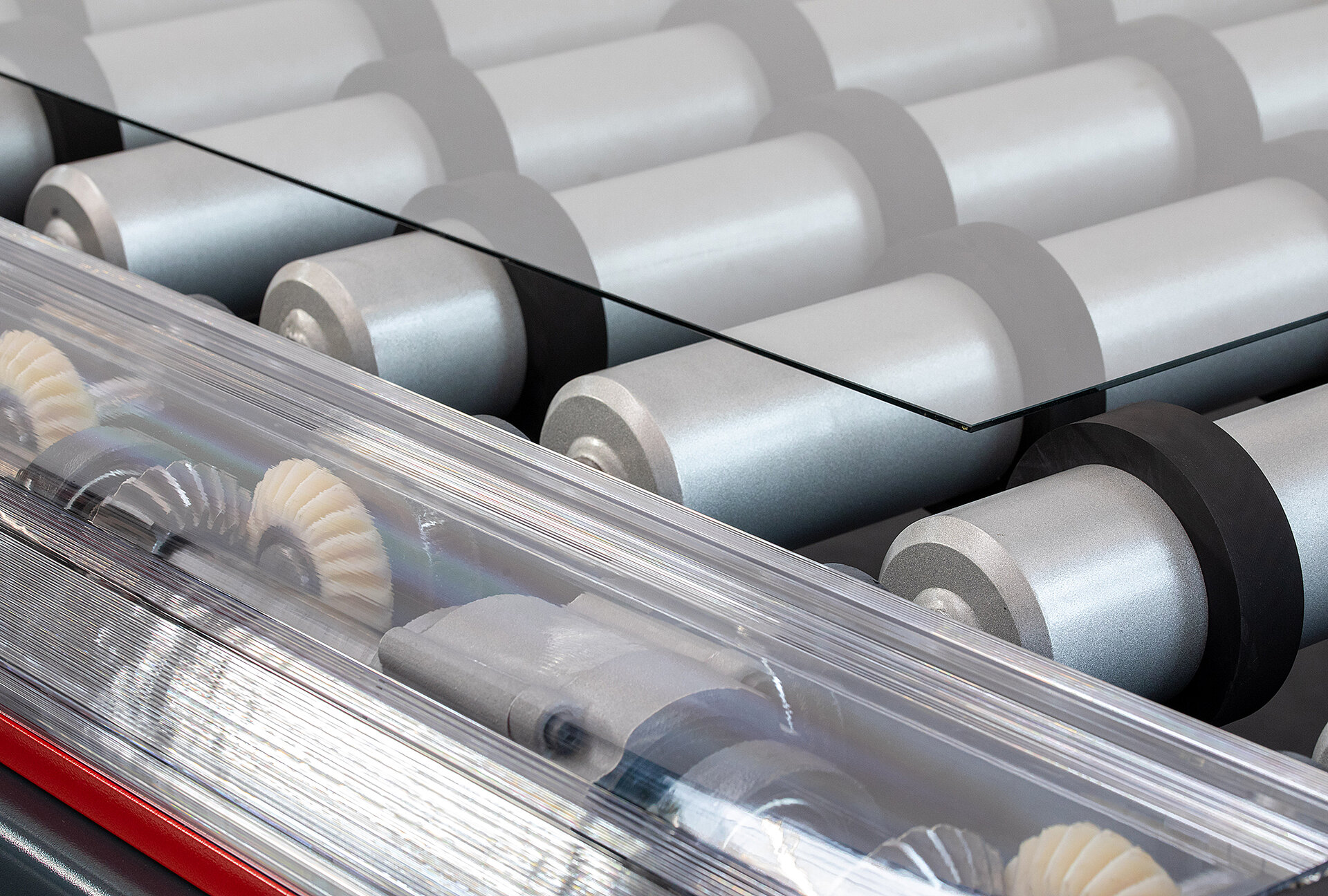

Focus on Rollers

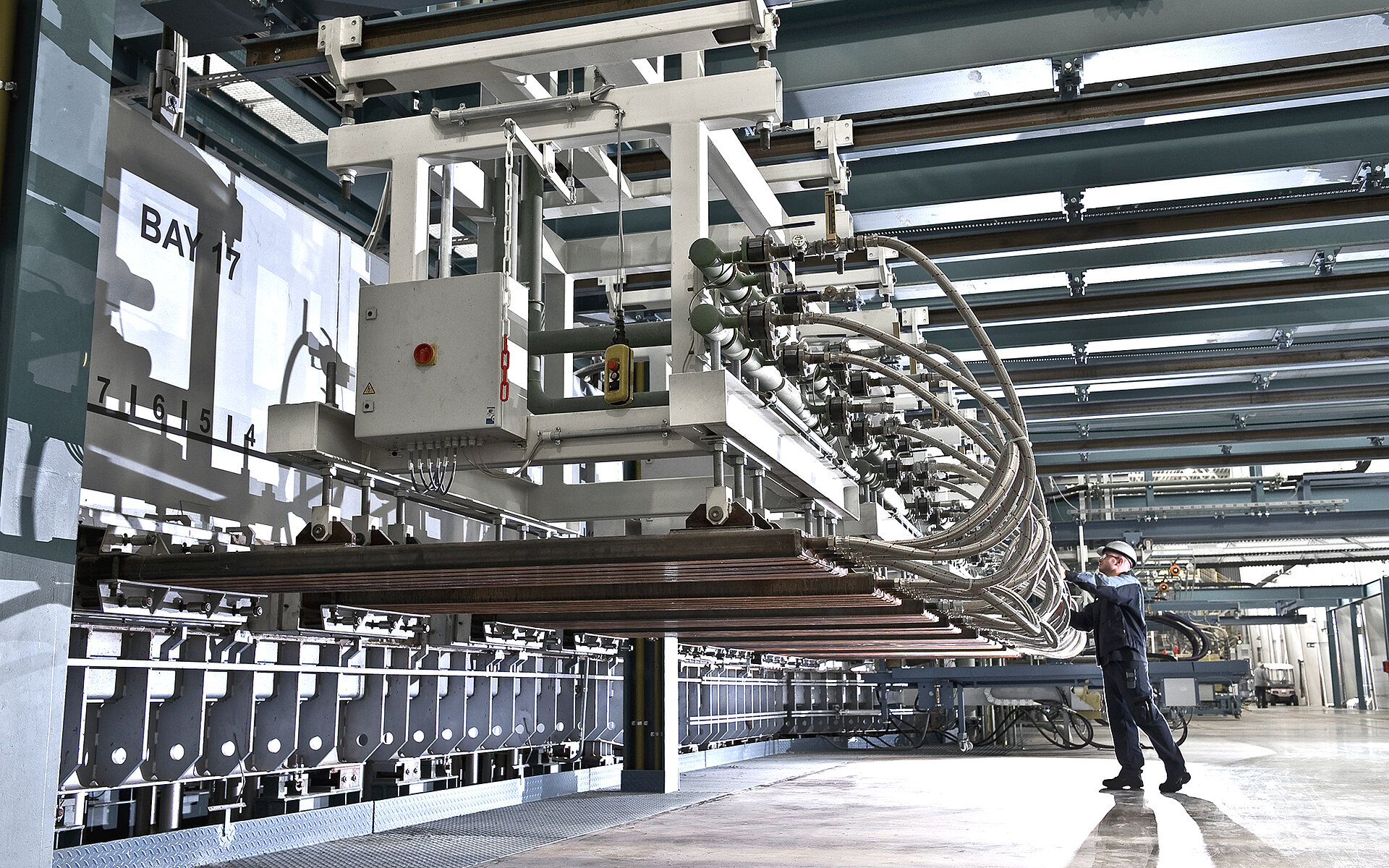

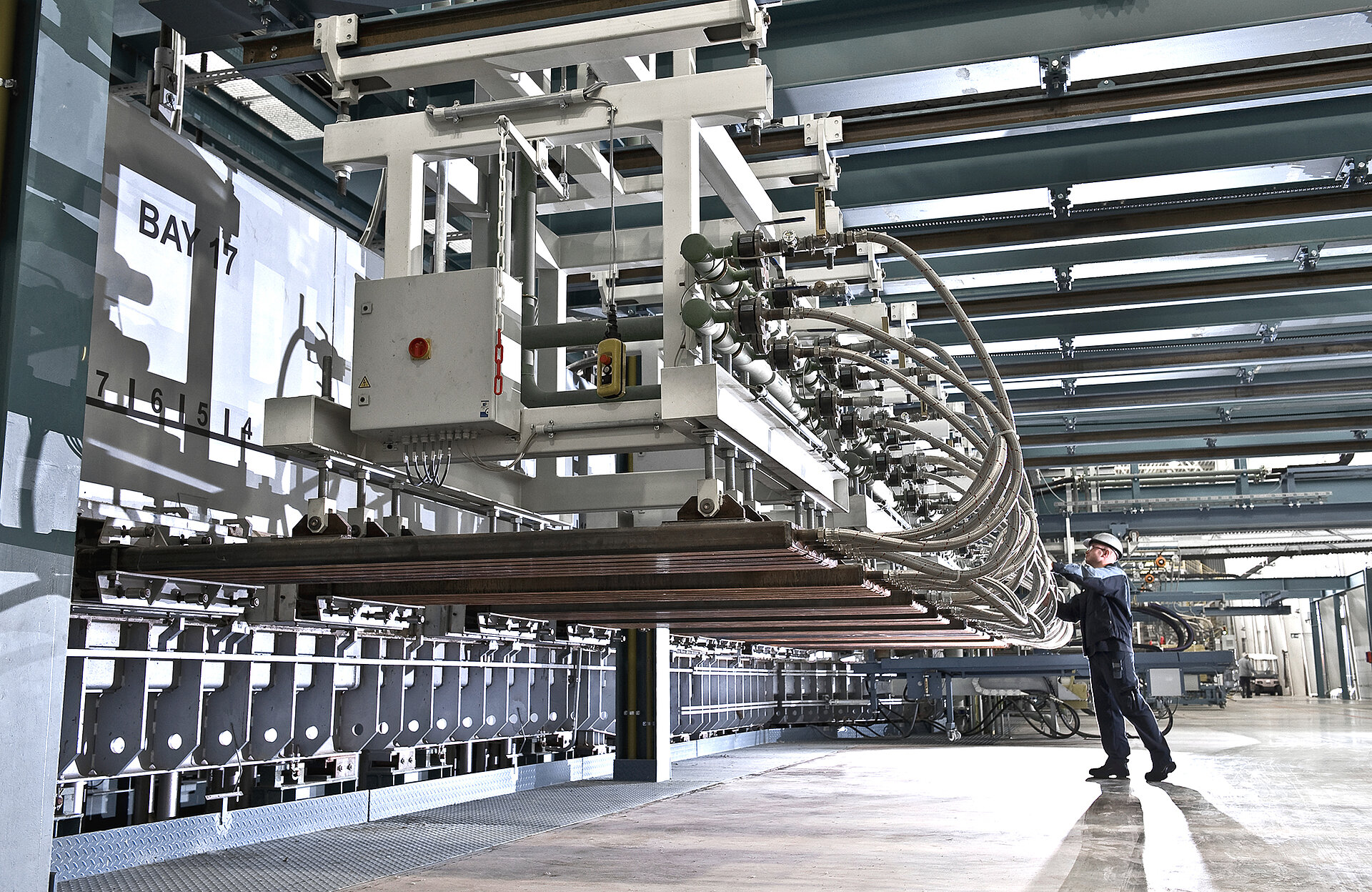

The glass ribbon, which is still flexible, is lifted out of the tin bath by three individually driven rollers (LOR = lift-out rollers) and conveyed to the annealing lehr. Thereby, the lift-out rollers form a curve geometry, which can be adapted to the respective production requirements by individually adjusting the height of each roller. This also allows for an equal distribution of the load on all rollers. The result is a flexibly adjustable lift-out curve with settings that can be saved for the respective glass thicknesses.

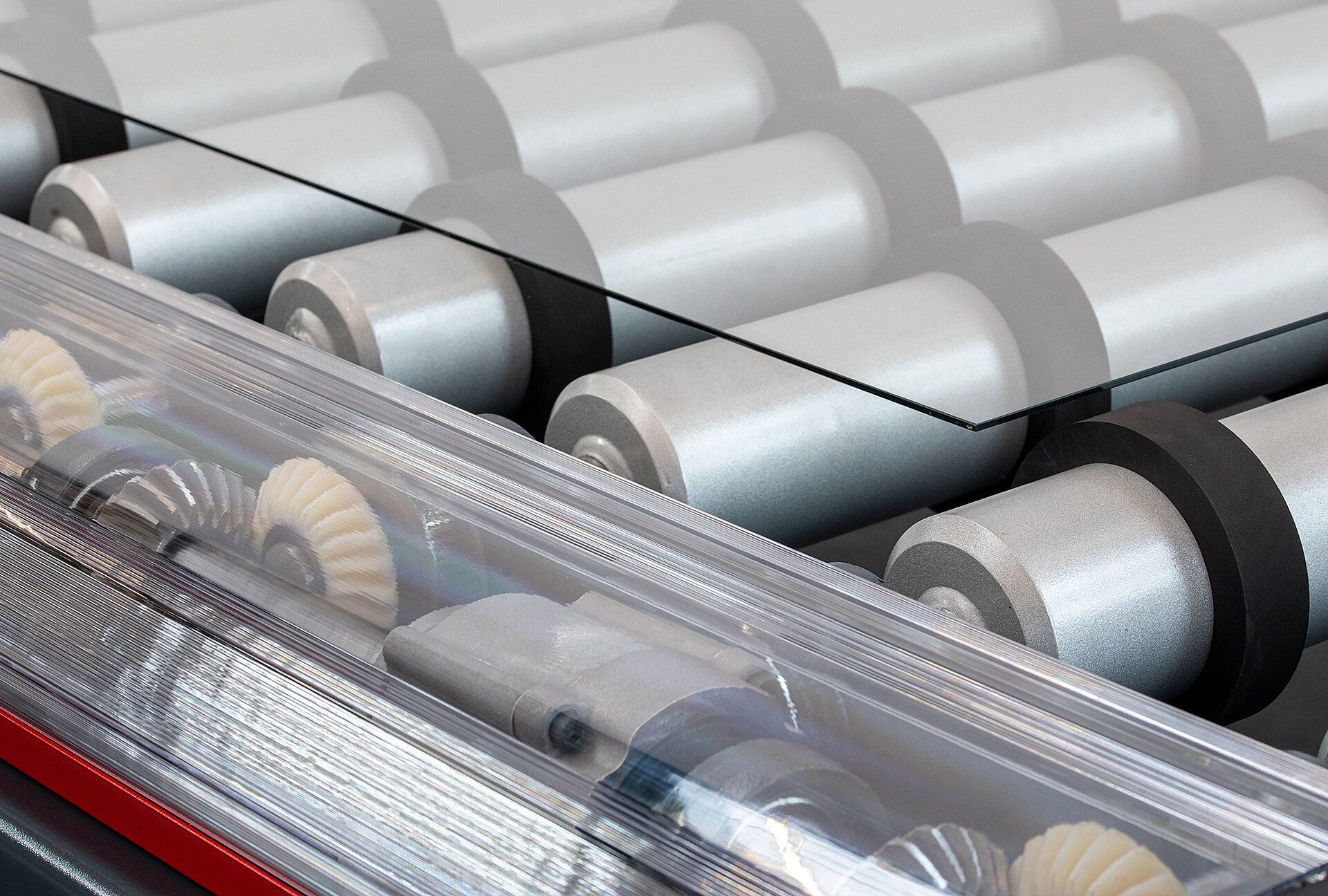

The special roller sealing contributes to a particularly high level of insulation of the Grenzebach dross box. This results in less heat loss and a more homogeneous temperature distribution across the entire width of the glass. The ambient temperature at the edge no longer substantially deviates from the temperature in the center of the glass ribbon. This provides better glass quality and reduces the risk of a cross breakage.

The rollers are constantly cleaned over three-part graphite bars with pneumatically adjustable contact pressure to ensure a clean process.

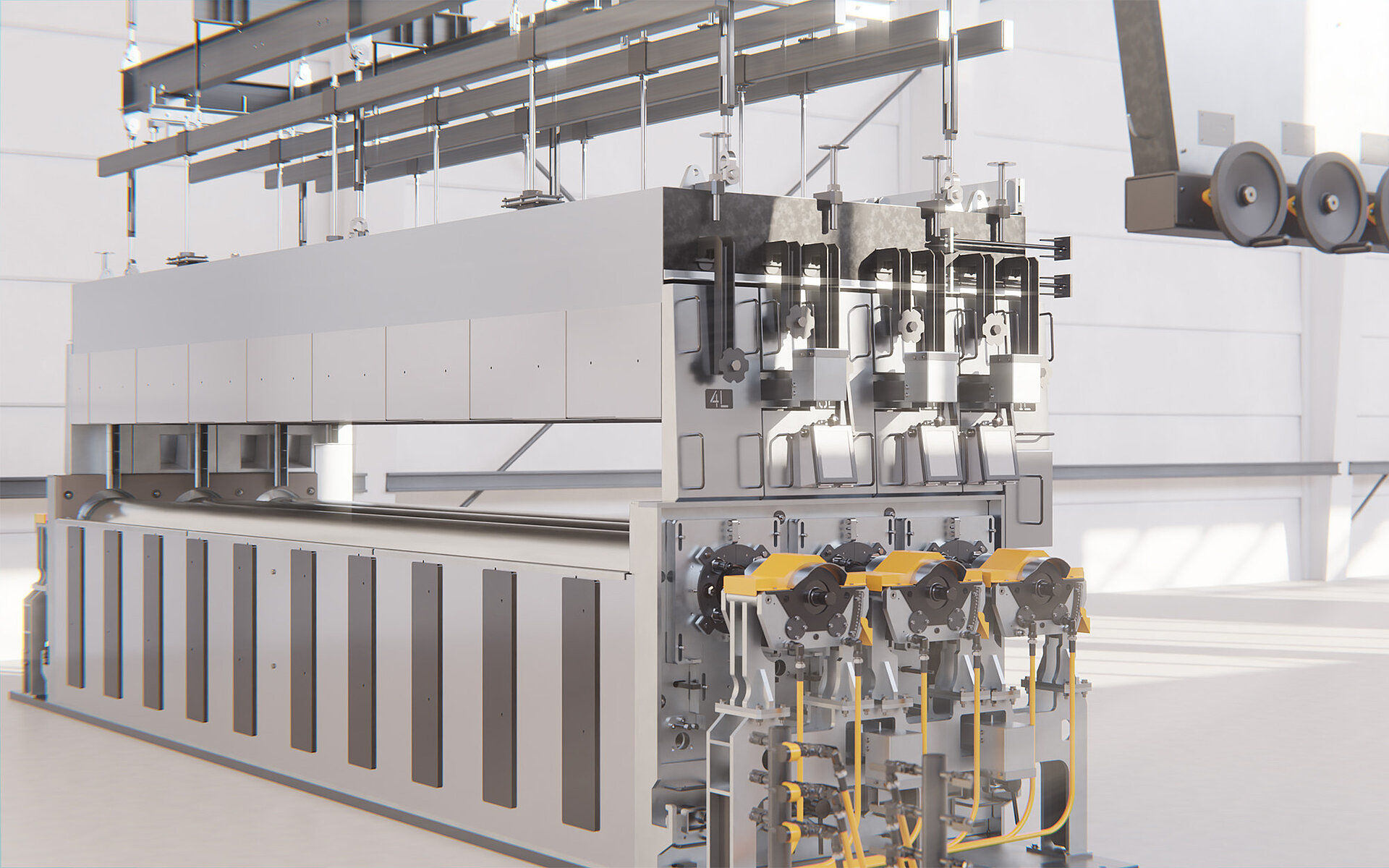

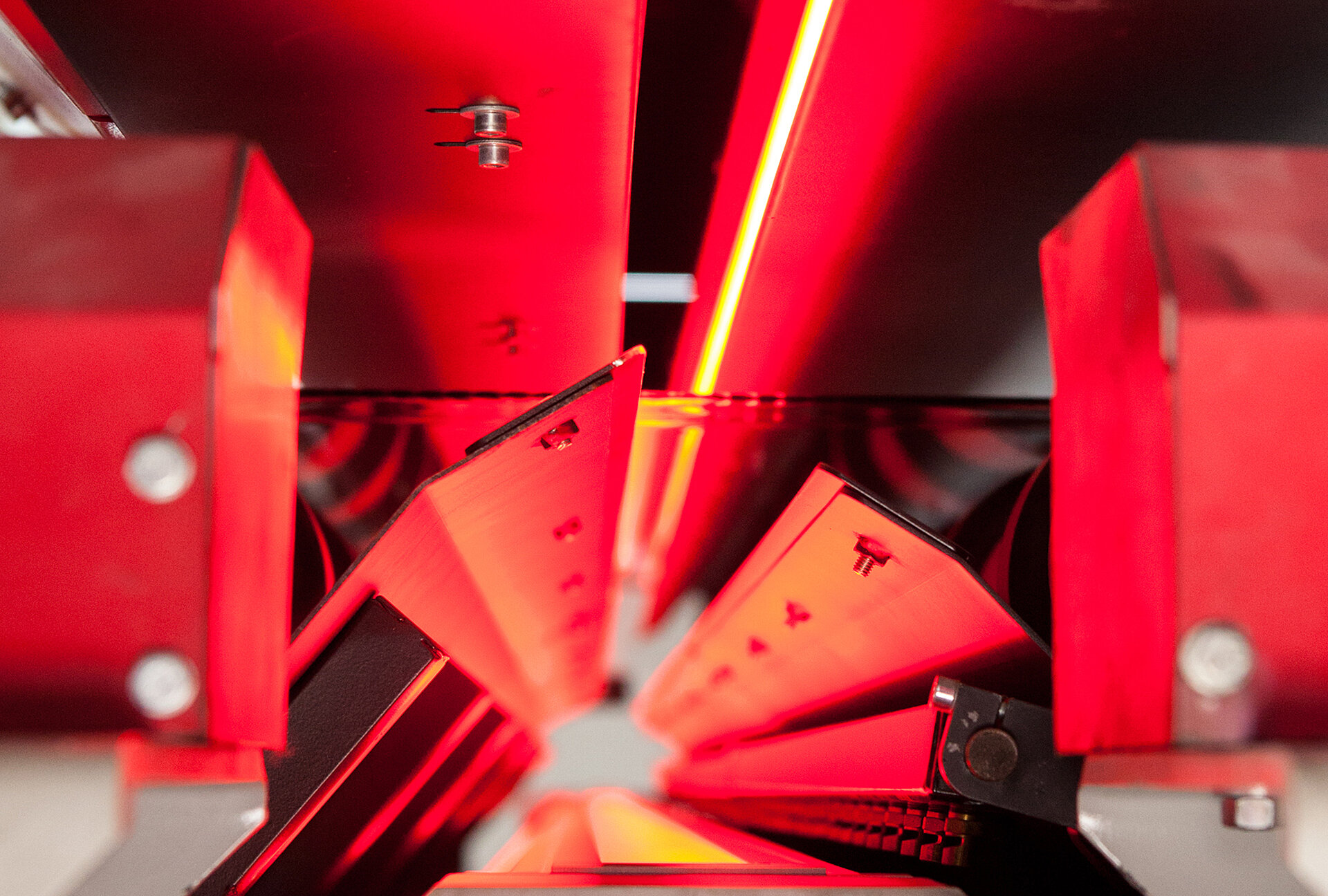

Focus on Housing

The dross box is not welded to the tin bath but attached to it by means of a clamping device, which is firmly fixed after the tin bath has heated up to 620 ° C. This way, thermal expansion is accounted for and deformations due to heat effects will neither occur on the housing nor on the U-channel.

Maintenance and Operation

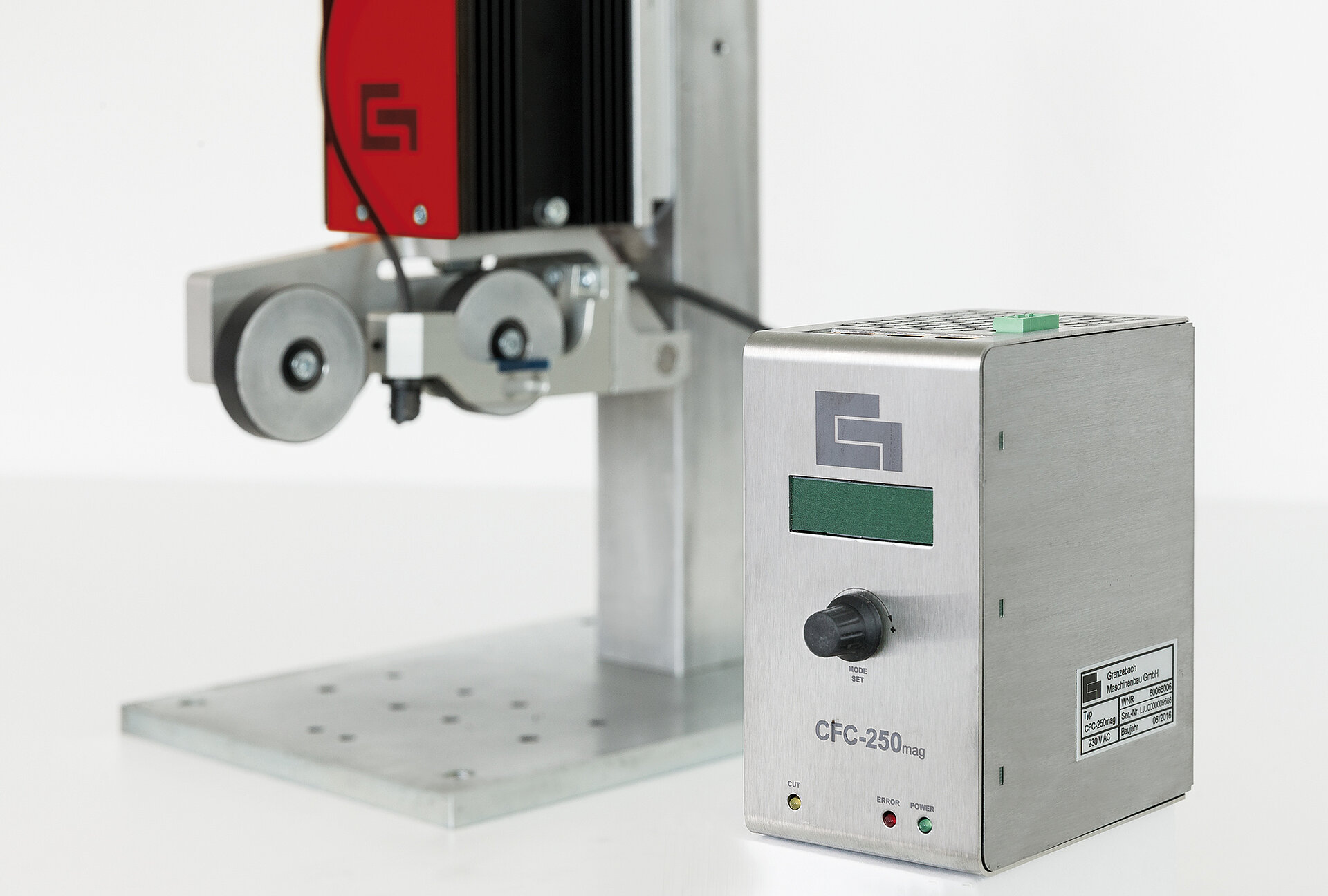

The Grenzebach dross box can be locally and decentralized controlled with the innovative user interface. During maintenance, operators benefit from increased work safety and improved accessibility to the end plate and when changing rollers. Rollers can be changed during operation. The resulting glass loss during roller exchange is minimal. Similarly, the graphite bar exchange can be performed quickly and easily in a very short time.

“Grenzebach has accepted the challenge of the hot end and, with the dross box, provides ideal conditions for the production of high-quality glass. The dross box is now brought to a whole new level with innovative technologies with exemplary safety and characteristic design, realized with the highest Grenzebach design standards.”