Phosphorus Recycling: Meeting Legal Requirements, Acting Ecologically and Economically Sensibly

Sustainable. Environmentally friendly. Easy.

From 2029, towns, cities and municipalities will have to recycle the essential raw material phosphorus from sewage sludge. The Grenzebach Phosphorous Recycling Process will enable them to do this sustainably, without the need for upstream incineration, long transportation routes, landfill materials or the use of chemicals in the recycling process. An approach that can be implemented regionally and which allows municipalities to meet legal requirements. Being one of the few processes that recycle phosphorus directly from sewage sludge, it exceeds the recycling rates specified by government regulations.

Here You Will Find:

Legal Reporting Obligation of Municipalities

By the end of 2023, municipalities in Germany must report to the competent authority their planned measures for phosphorus recycling from January 2029 (cf. Section 3a German Sewage Sludge Ordinance 2017).

Why Phosphorus Recycling Is So Important Today

GOOD REASONS FOR PHOSPHORUS RECYCLING

- Phosphorus is a vital nutrient for plants, animals and humans. It supports plant growth and the energy metabolism in the human body. This renders phosphorus an essential resource in fertilizer production and an important component of numerous products such as animal feed and pharmaceuticals.

- Germany is completely dependent on phosphorus imports from fossil deposits. Therefore, the European Commission categorizes phosphorus as one of 30 critical raw materials.

- The greatest potential for recycling lies in the municipal sewage sludge from the approximately 9,600 wastewater treatment plants. That is why recycling from sewage sludge will be mandatory from 2029.

- Phosphorus recycling enables a sustainable circular economy and increases the security of supply for the economy.

Basic Decision: Direct Phosphorus Recovery From Sewage Sludge or Indirect Recovery via Incineration?

HOW PHOSPHORUS CAN BE RECYCLED

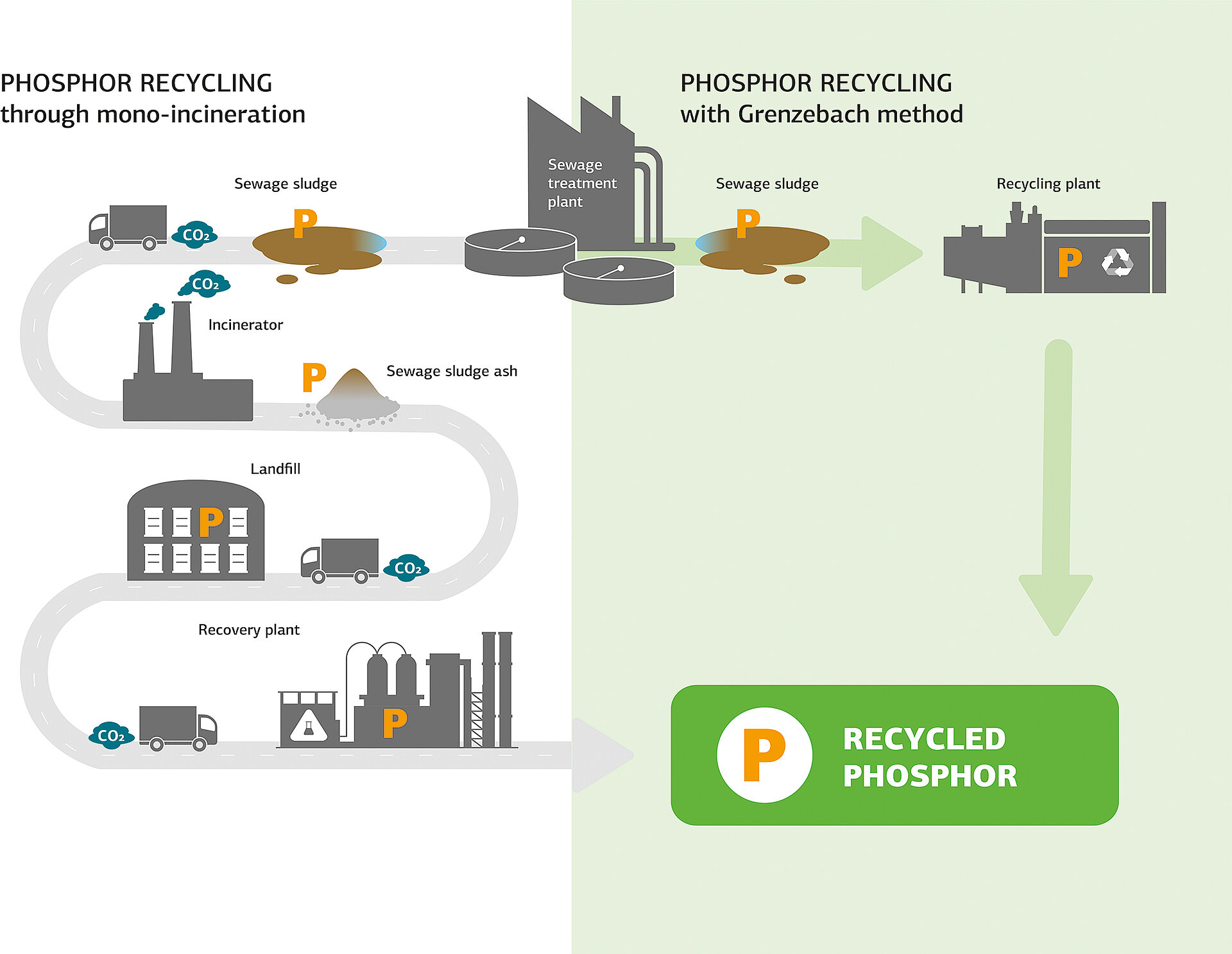

Currently, two different approaches have been established: Direct recovery from sewage sludge or indirect recovery from sewage sludge ash after mono-incineration. Both ways lead to the same result, but have different potentials in terms of efficiency and sustainability:

Phosphorus Recycling via Mono-Incineration

For the indirect recovery of phosphorus from sewage sludge ash, the sludge is initially burned unmixed in a mono-incineration plant. The main challenge, however, lies in a complex process chain that will only be economically viable at high recycling capacities. Numerous transports to central plants are necessary in this approach, resulting in increased CO2 emissions. The indirect recovery of phosphorus from sewage sludge ash is only possible through the high use of chemicals. This form of recycling means the sewage sludge ash needs to be landfilled unmixed as an interim solution but it does not eliminate the need to recover the phosphorus in a further step. This is just another cost factor with a negative impact on the environment.

Phosphorus Recycling From Sewage Sludge

Direct recovery of phosphorus from sewage sludge provides municipalities with a regionally oriented and independent solution: Phosphorus is recycled from the dewatered sewage sludge via the recycling plant located at the wastewater treatment plant. This very efficient and sustainable approach avoids high transport costs and the resulting CO2 emissions altogether. Due to the small size of the plant, comparable to the dimensions of a handball court, this approach also scores with its small space requirement and offers smaller, local plants a practical solution. Today, Grenzebach combines these promising potentials with high recovery rates in its recycling process.

This Is How the Grenzebach Phosphorus Recycling Works

OUR PHOSPHORUS RECYCLING CONCEPT: SUSTAINABLE AND ECONOMICAL IN THE LONG RUN

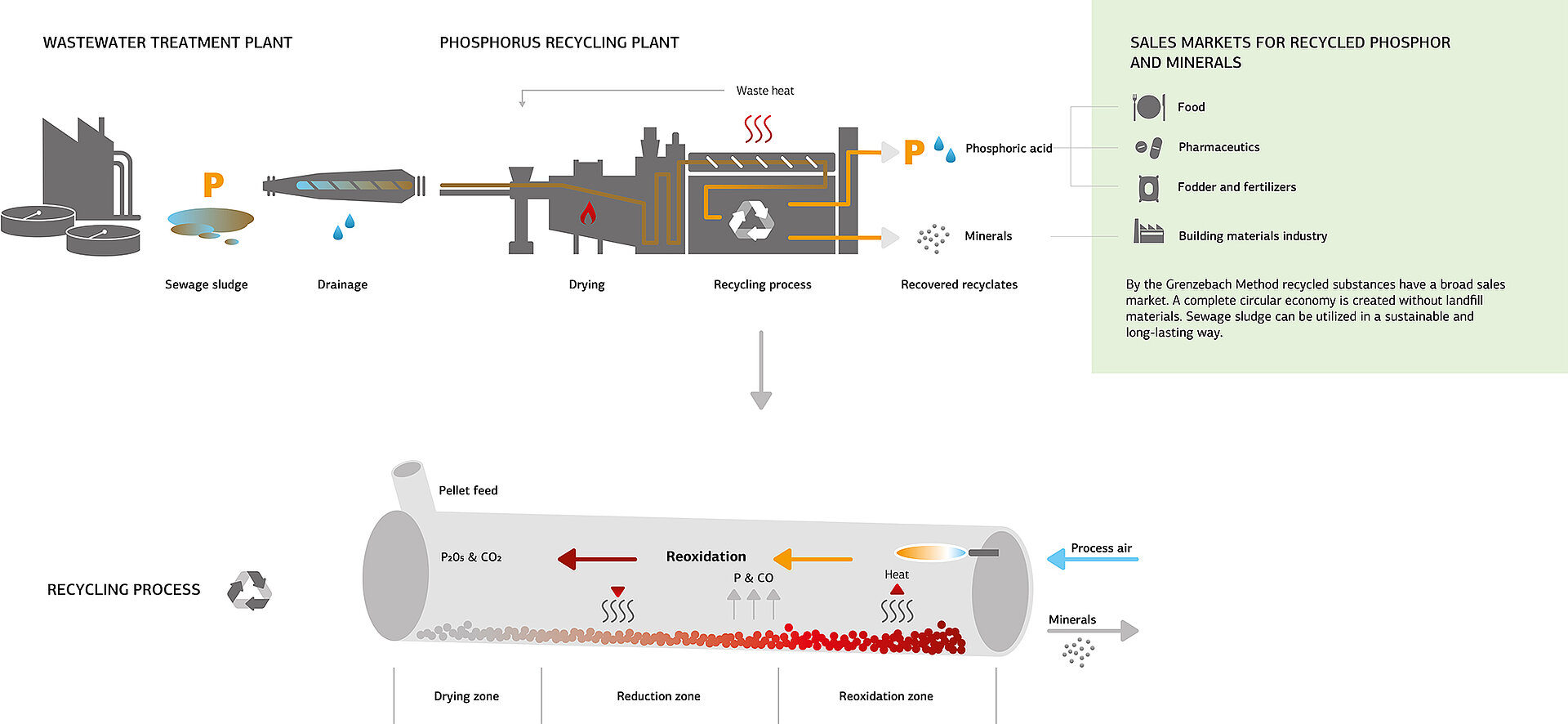

The Grenzebach Phosphorus Recycling Process is decentralized and can be implemented directly at the wastewater treatment plant. Municipalities are thereby provided with a regional solution independent of third parties.

The process starts with dewatering and drying the sewage sludge, which for the most part is done in an energy-efficient manner by using the waste heat from the recycling process. During this process, the sewage sludge loses around three quarters of its weight without hazardous substances being emitted. The core of the recycling process is the reduction and oxidation control of the sewage sludge dry matter. The remaining dry matter is almost completely recycled into phosphoric acid and minerals in this process - without producing any further landfill material.

How You Can Benefit From the Grenzebach Phosphorus Recycling Process

Protects the Environment

A phosphorus circular economy is established. The sewage sludge is completely recycled into new raw materials without landfill material being left over. Thanks to the direct recovery, the transport of millions of tons of sewage sludge to the mono-incineration plants is not necessary.

Valuable Final Products

The dry mass is almost completely recycled into phosphoric acid and minerals. Phosphoric acid has a very broad sales market. The same applies to minerals in the construction industry.

Cost-Efficient Over the Long Term

Doing without chemicals in the recycling process means no chemicals have to be paid for. The automated operation reduces staff costs and the completely usable end products help refinancing the investment.

For Municipalities of All Sizes

The plant concept is adaptable to different recycling capacities and therefore also suitable for municipalities with less than 3 tons of sewage sludge per hour. The plant requires no more space than a handball court.

Phosphorus Recycling: Decide and Act Sustainably Today – for Our Future

We all need phosphorus – Animals, humans, and plants. It is a finite resource that is already deciding our future today. But have you ever thought about phosphorus and the impending challenge?Watch our video to learn about the inherent potential of phosphorus recycling from sewage sludge to preserve this important resource for future generations and establish a sustainable circular economy.♻

Our Expertise and Know-How for You

Grenzebach is a renowned German plant engineering and automation specialist rooted in a tradition of process engineering and raw material processing. With its many years of experience in phosphoric acid production, the company now contributes proven process technology to the recovery of phosphorus.

The Grenzebach Phosphorus Recycling Process was developed in cooperation with the CUTEC research center of the Clausthal University of Technology.

Comprehensive support for municipalities

FROM A SINGLE SOURCE

FAQ – Frequently Asked Questions

Why Is Phosphorus So Important?

Phosphorus is vital for plants, animals and humans. It supports plant growth and the energy metabolism in the human body. This renders phosphorus an essential resource in fertilizers productions and an important component of numerous products such as animal feed and pharmaceuticals.

Germany and the other EU countries are completely dependent on phosphorus imports from fossil deposits. The extraction of natural phosphorus is becoming increasingly difficult, as natural resources contain high levels of uranium and harmful substances. The European Commission therefore categorizes phosphorus as one of 30 critical raw materials: i.e. a resource with a high supply risk and great economic importance.

What Is Phosphoric Acid and What Is It Used For?

Phosphoric acid is the most important oxygen acid of phosphorus and one of the most important inorganic acids. Its salts and esters are called phosphates.

As a final product, phosphoric acid has a very wide range of applications and serves as a base material for a variety of products, such as:

- Fertilizers

- Corrosion inhibitors

- Pharmaceuticals

- Food

- Animal feed

- Catalysts

- Flame retardants

- Detergents

Why Should Phosphorus Be Recycled From Sewage Sludge?

Significant amounts of phosphorus currently enter wastewater and thus sewage sludge through the human food cycle. It is estimated that each person excretes 1.8g of phosphorus per day. Sewage sludge therefore has by far the greatest potential for phosphorus recovery. The German Federal Environment Ministry estimates that up to 40 percent of phosphorus imports could be replaced in Germany if this recovery potential was fully exploited.

For sewage sludge containing 20 or more grams of phosphorus per kilogram of dry matter, the current Sewage Sludge Ordinance aims to recover 50 or 80 percent of the phosphorus content. That phosphorus content is found in the sewage sludge of about 500 wastewater treatment plants in Germany.

How Ecologically Sustainable Is Phosphorus Recycling?

A long-term, sustainable circular economy can be achieved with phosphorus recycling. Finite resources require a rethinking of our current actions. Secondary sources of phosphorus must therefore be made usable, so that this valuable resource is preserved for future generations.

However, to qualify as a holistically sustainable phosphorus circular economy, phosphorus recycling must be in line with all aspects of environmental and climate protection - from energy consumption and CO2 emissions to the recyclability of the end products.

The innovative Grenzebach Process, which extracts phosphorus directly from sewage sludge, makes phosphorus recycling sustainable without the need for incineration, long transport routes, storage or the massive use of chemicals.

The recovery from sewage sludge ash, on the other hand, is an ecological disaster in many ways: Mono incineration is only viable in large plants. Transporting hundreds of thousands of tons of sewage sludge to the incineration plants is a burden on residents and has an enormous CO2 footprint.

How Great Is the Marketing Potential of the Recovered Materials?

The marketing potential of recovered materials depends on the nature and purity of the recycled products.

The Grenzebach Process almost completely recycles the sewage sludge to phosphorus acid and minerals, with no further landfill materials remaining. The phosphoric acid extracted in this process has a very wide range of uses in many branches of the industry. Well beyond the fertilizer industry, phosphoric acid can be used, for example, as a commodity in the food industry, or the chemical industry. The same applies to the recovered minerals, which are used in the production of building materials and can replace basalt, which is otherwise extracted in mines in an ecologically harmful way.

In comparison, other processes recover phosphorus in the form of struvite or bonded with other chemical substances. The end products thereby recovered find further use primarily in niche areas.

Which Municipalities Benefit From the Grenzebach Phosphorus Recycling Process?

Municipalities that are particularly committed to sustainable circular economy and strive to be among the pioneers in environmental protection.

The process is suitable for the many municipalities that use aluminum- or calcium-based agents in phosphorus precipitation or plan to do so in the future. It can be easily implemented, in particular in smaller municipalities where less than 3 tons of sewage sludge are produced per hour. At this scale, no lengthy public approval processes are required by law.

The compact plant will usually take up no more space than a handball court. It is fully automated and remotely managed, requiring no additional personnel.

What Qualifies Grenzebach for the Recycling of Phosphorus?

As a leading company for equipment technologies, our day-to-day work involves the thermal, mechanical and chemical processing of a wide variety of raw materials across many industries. Our many years of experience in phosphoric acid production are the foundation for our in-depth expertise in phosphorus processing. We understand the element phosphorus, its complexity and in its reaction behavior. Proven process engineering equipment, for example for phosphoric acid production from apatite or the sodium tripolyphosphate process, forms the basis of our plant concepts.

Contact

Your Contact Person: Mathias Fälber

Let's use phosphorus recycling as an opportunity together! With a method and a plant that meet legal requirements and create an environmentally friendly, efficient circular economy in your municipality.