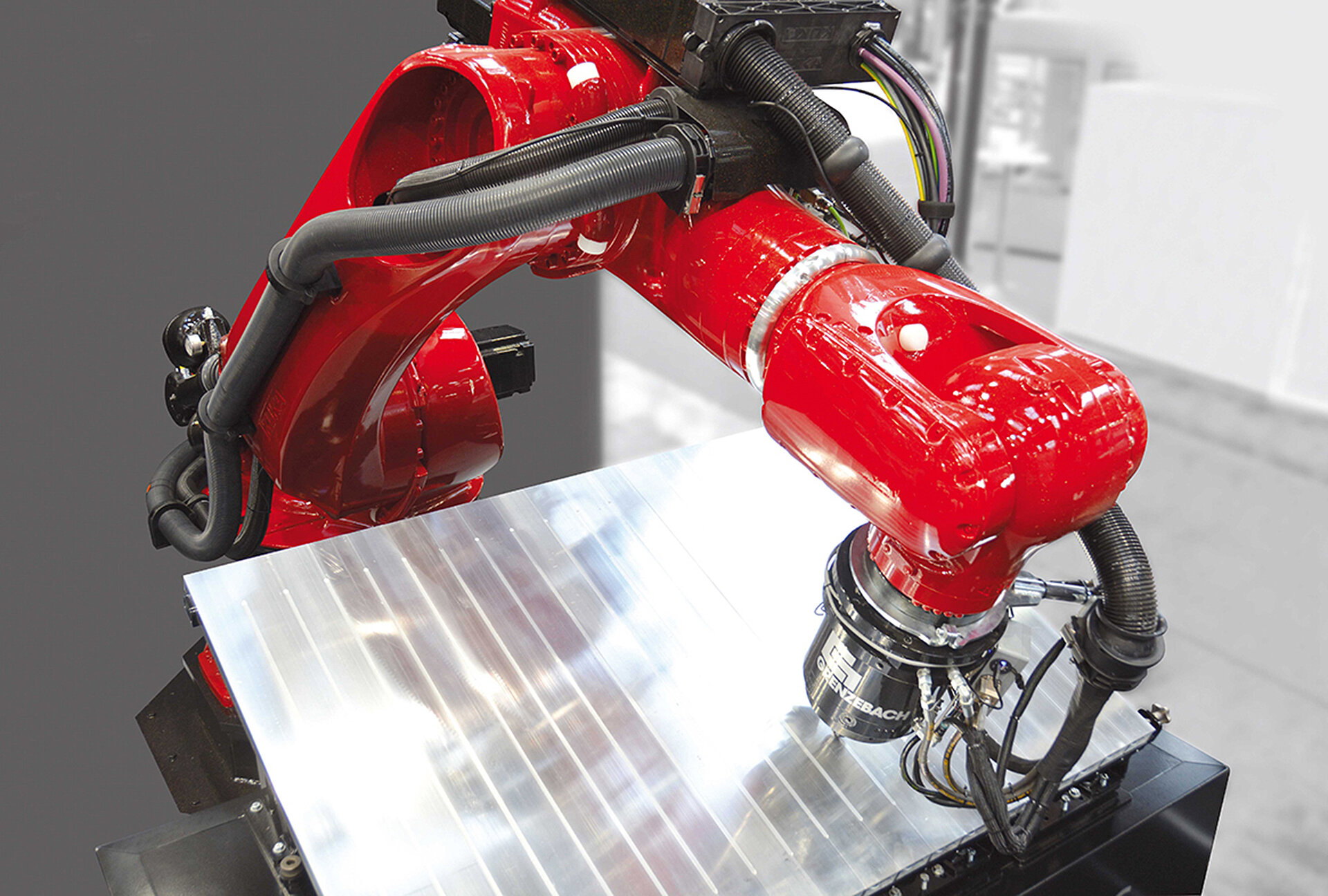

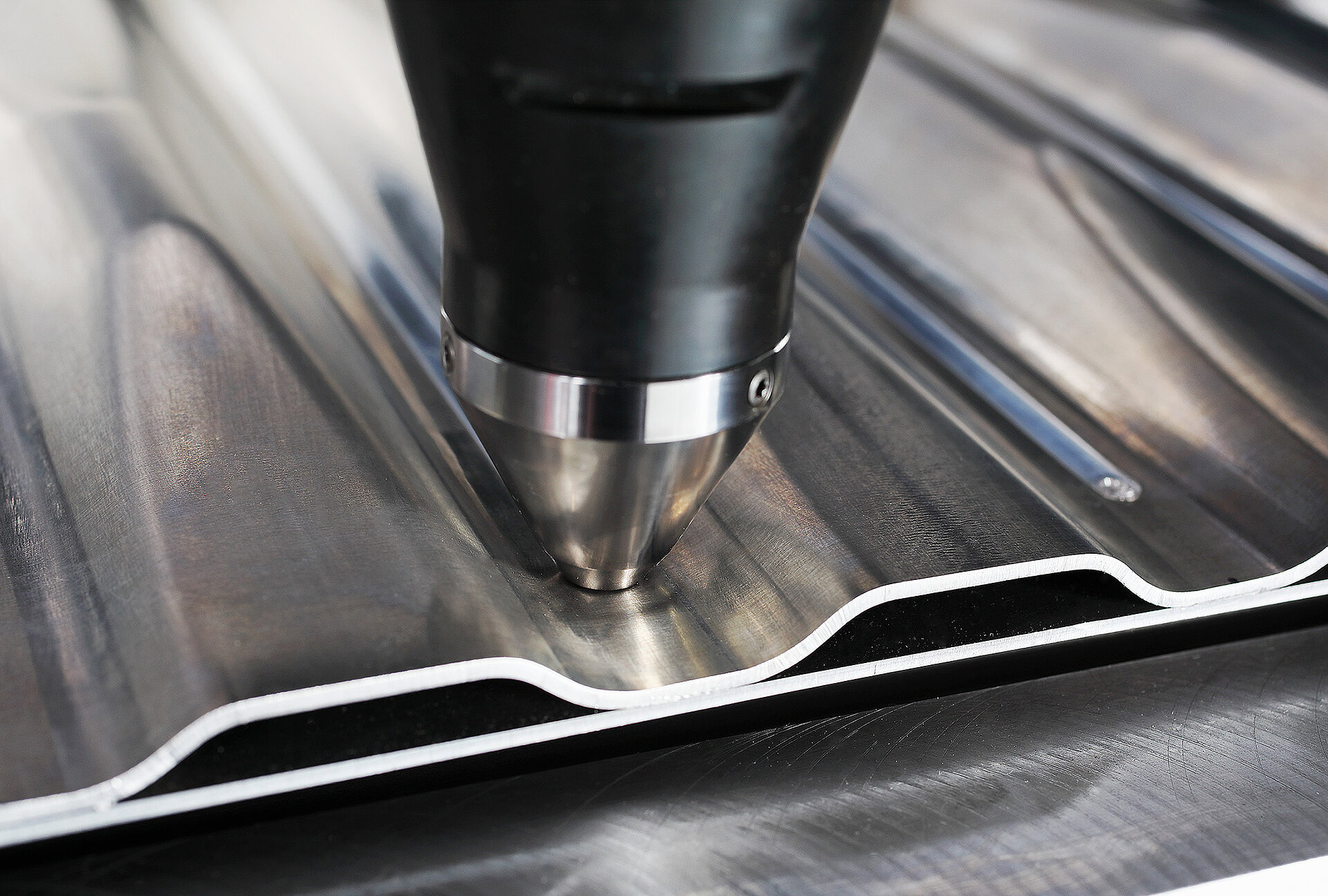

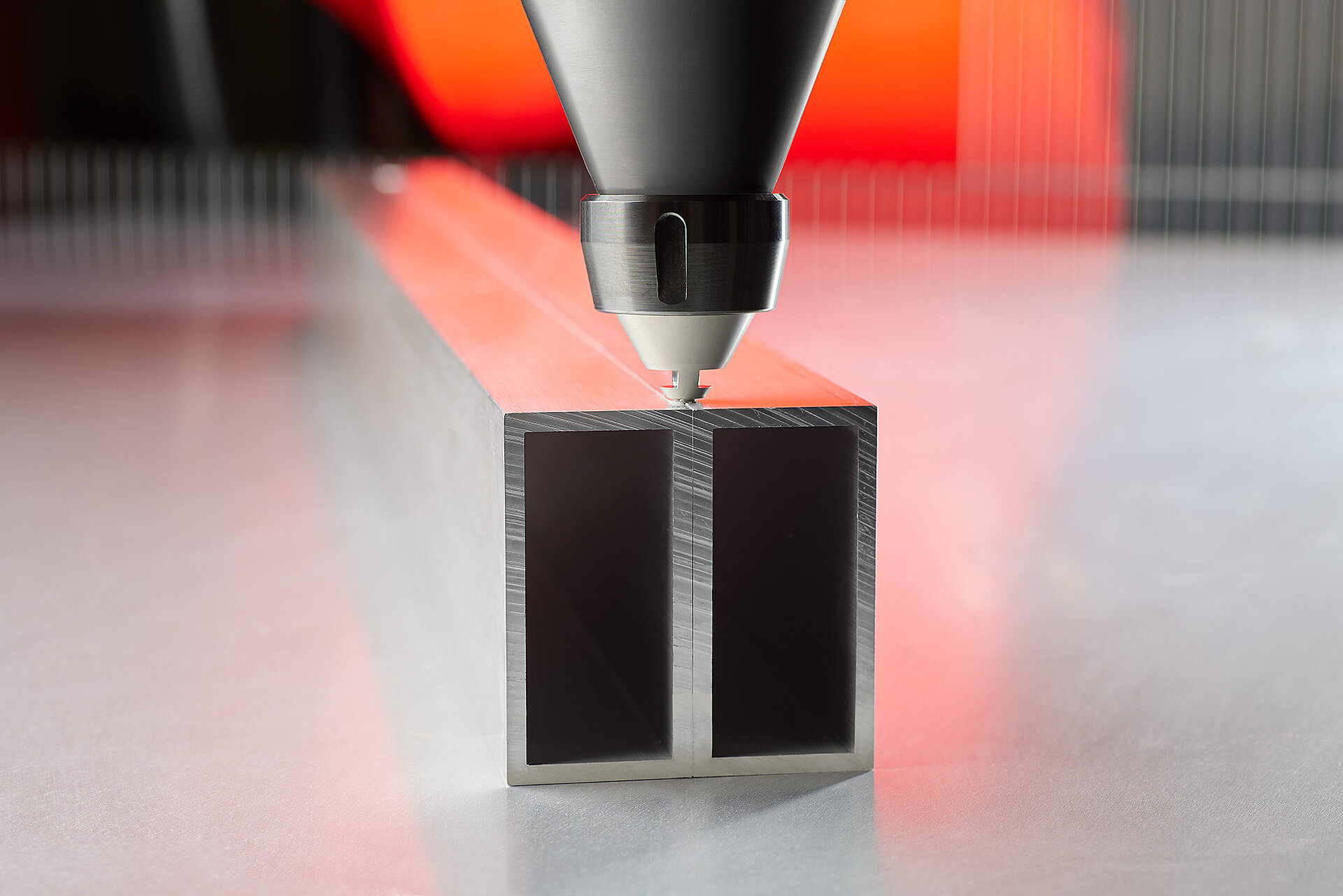

The right choice of tools, the precise deployment of force sensor technology, the control of all processes, the lead machine, and machine and process control: all of these contribute to an optimal weld seam and surface finish and thus to the quality of your component. We support on each step so that you can capitalize on the strengths of the friction-stir-welding process.

We work closely with our customers to develop the joining concept.

- As early as the component design phase, we support you with the selection of the module that is best adapted to the FSW process.

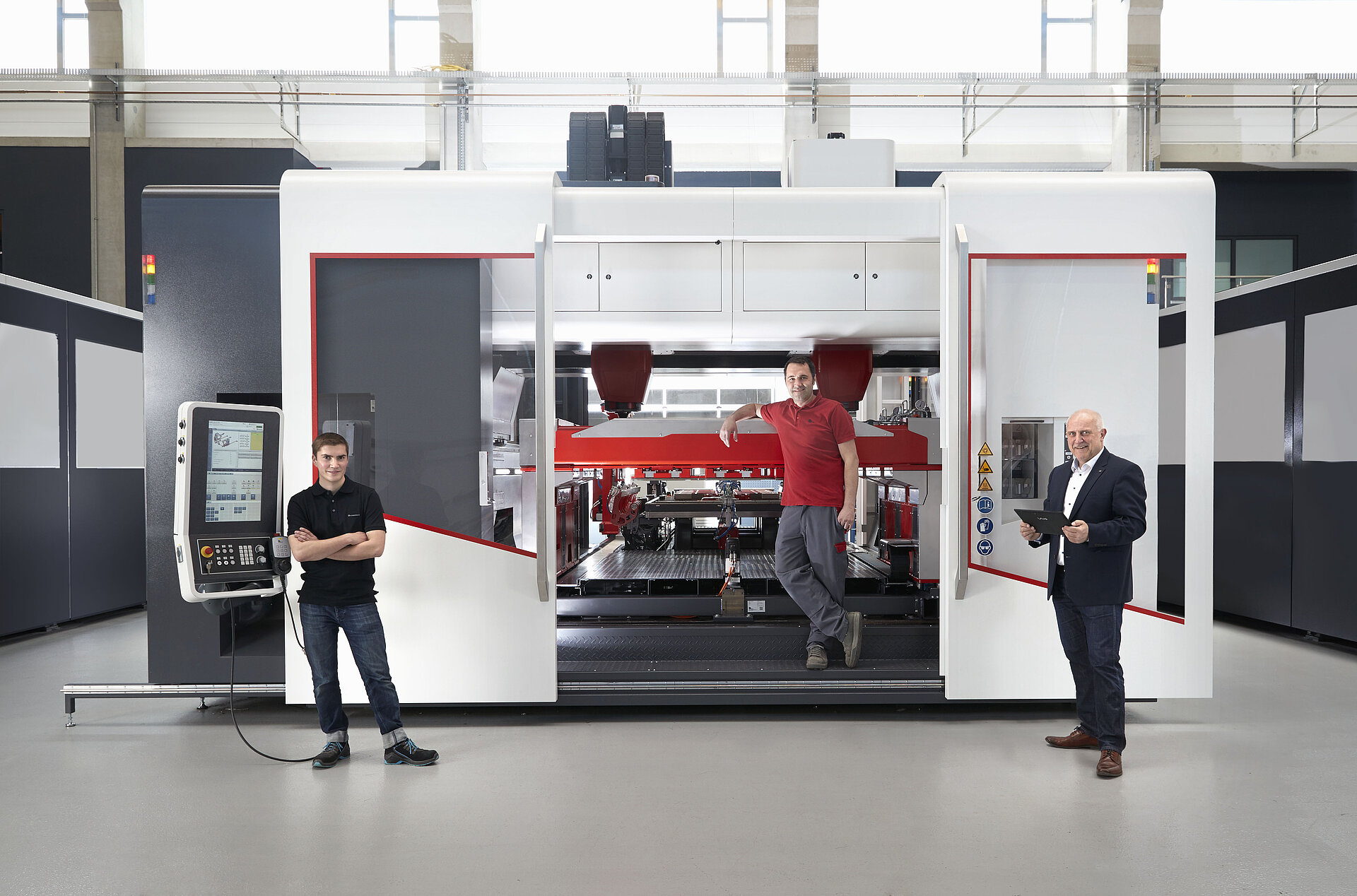

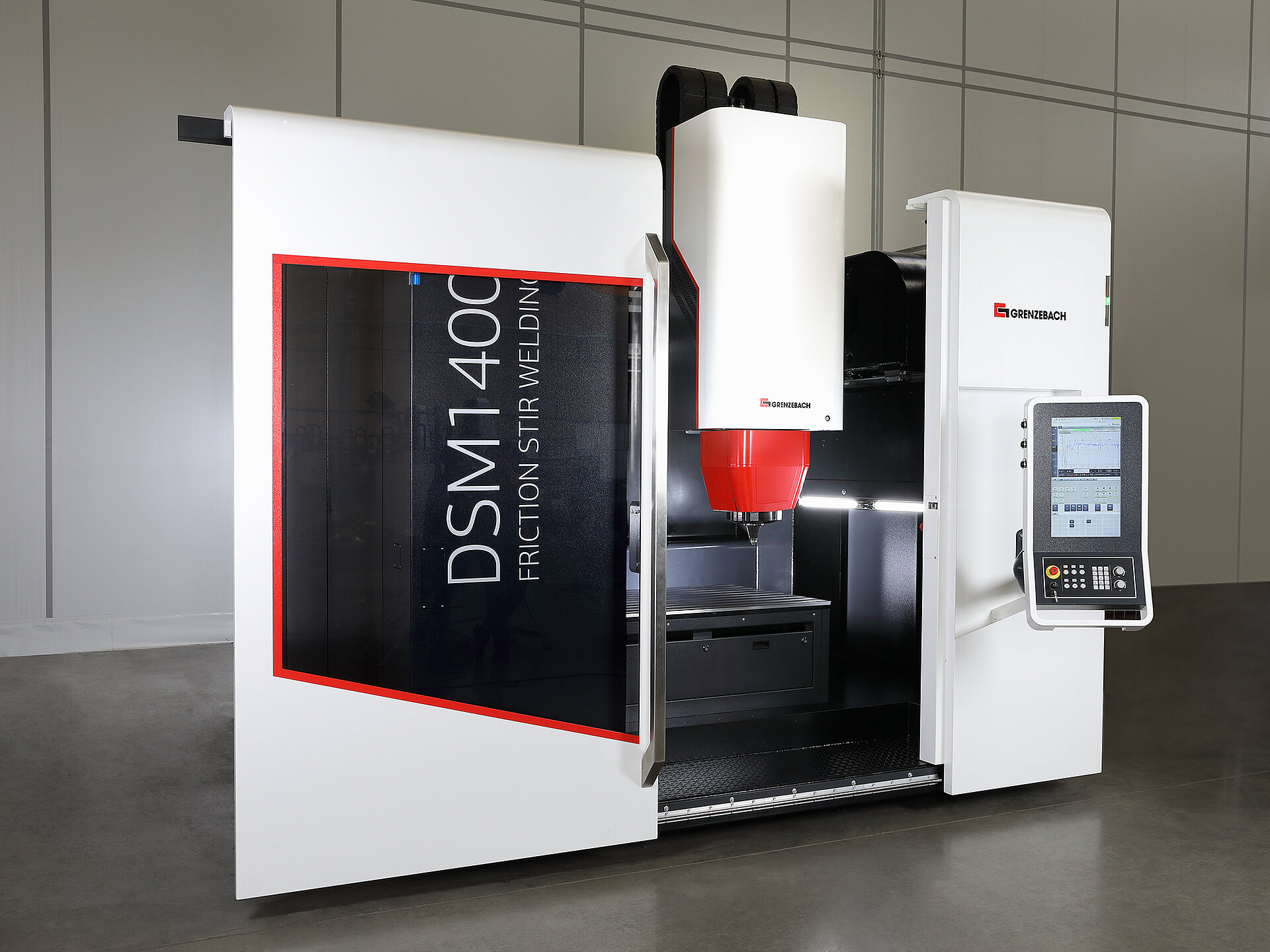

- Test, model and prototype welding, as well as contract production mandates, are all possible on Grenzebach’s in-house FSW facilities.

Take Advantage of Our Equipment and Tool Portfolio!

Friction stir welding – solutions for your specific needs

“Friction stir welding is a relatively young, but undeniably leading-edge, welding process for industry. Together with you, we determine how FSW can be optimally applied to your components. Our experts will provide you with the appropriate system and will remain at your disposal – anywhere in the world – whenever questions or concerns arise. And it goes without saying that that applies not only during commissioning but throughout the system’s lifecycle.”

Friction Stir Welding – A Green Technology

Protects Employees

Dust, gases, fumes, radiation – friction stir welding doesn’t produce any of these. This ensures a healthy workplace. In addition, the technology is quieter than conventional welding processes, and friction stir welding is CO2-free.

Conserves Resources

Auxiliary materials such as shielding gas, powder or welding wire are not required. The purchase and storage of operating materials are nearly eliminated. In addition, energy consumption is significantly lower than with classic welding processes.

Going Green

Media-tight battery trays or heat exchangers – our technology is used to create important components for electric vehicles. Mobility with green power – an important contribution to the energy transformation and climate protection in practice.

For North America

Your Contact Person: John Fluker

Do you have questions about friction stir welding? Would you like to know whether a new idea can be implemented with FSW? Or do you need support in selecting a system? Please contact us. We'll be happy to advise you!

For all other regions

Your Contact Person: Sahin Sünger

Do you have questions about friction stir welding? Would you like to know whether a new idea can be implemented with FSW? Or do you need support in selecting a system? Please contact us. We'll be happy to advise you!