Your Tailor-Made Gypsum Block – High-Performance for Fast and Efficient Interior Construction

GYPSUM BLOCKS ACCORDING TO YOUR REQUIREMENTS

Stable, flexible, and quick to use, gypsum blocks have to meet specific requirements to function as partition walls, supporting cladding or shaft walls. To fulfill your product promise, Grenzebach supports you with comprehensive process knowledge and technologies for gypsum block production. Based on your individual specifications regarding block thickness, format, and joint connection, we provide you with the required production solutions to make your individual gypsum blocks. With differentiated technologies designed for this purpose, we enable you to manufacture

- solid and hollow blocks

- blocks with tongue and groove

- blocks with high sound insulation and fire resistance

possible block thickness

the ideal size of a gypsum block

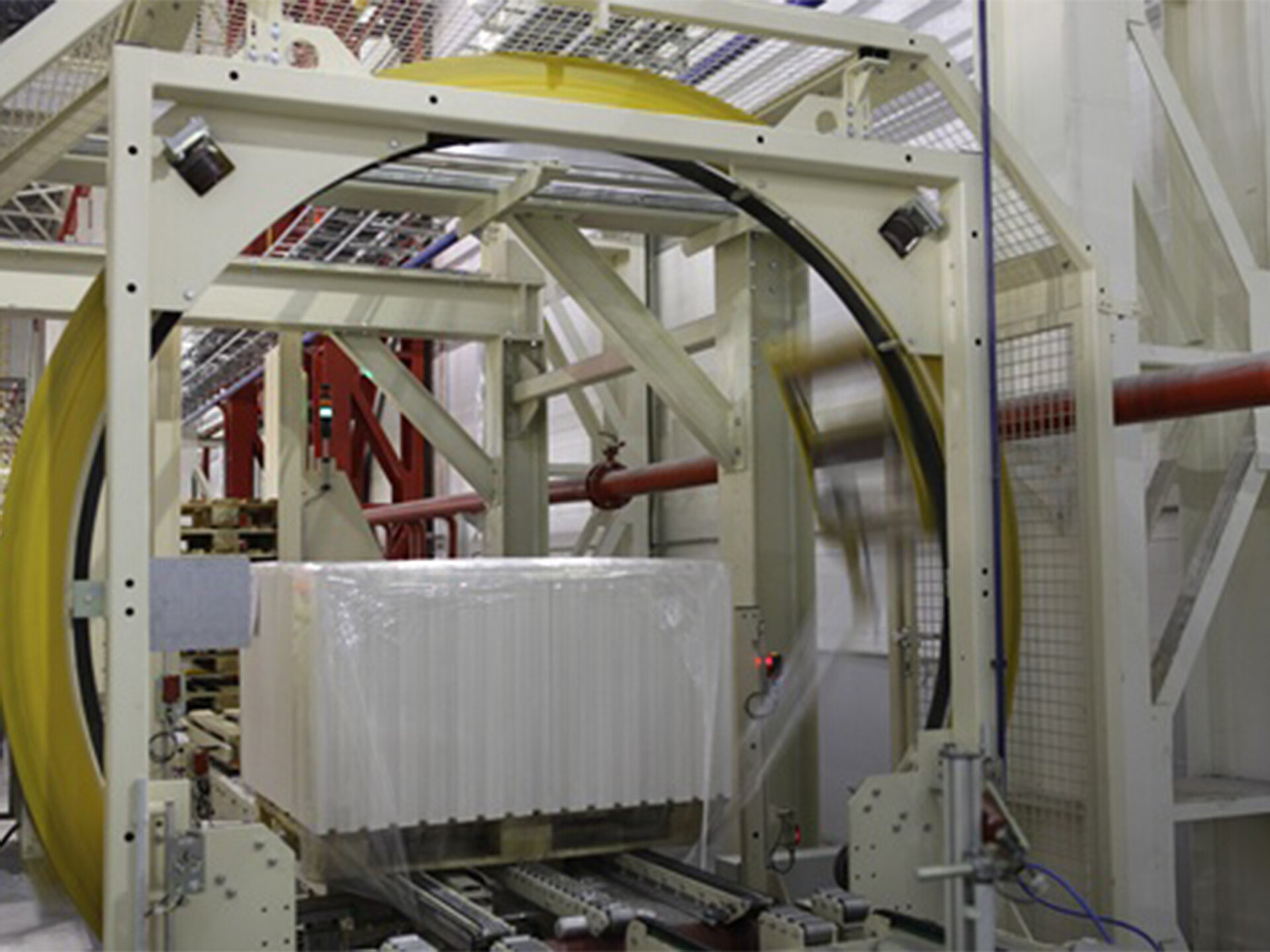

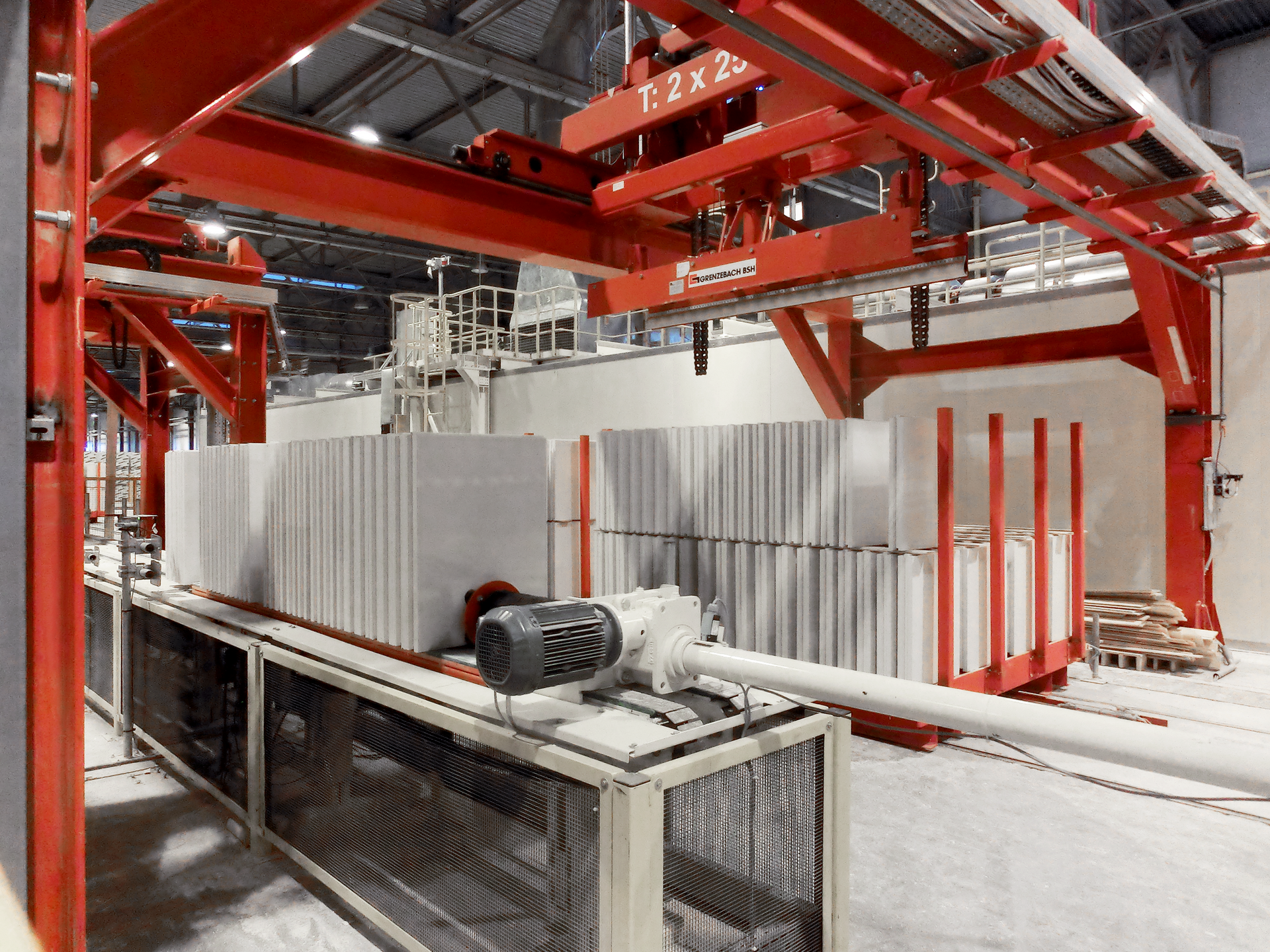

Full-Service Partner from the Preparing Station to Automated Packaging

PLANT CONCEPTS FROM GRENZEBACH

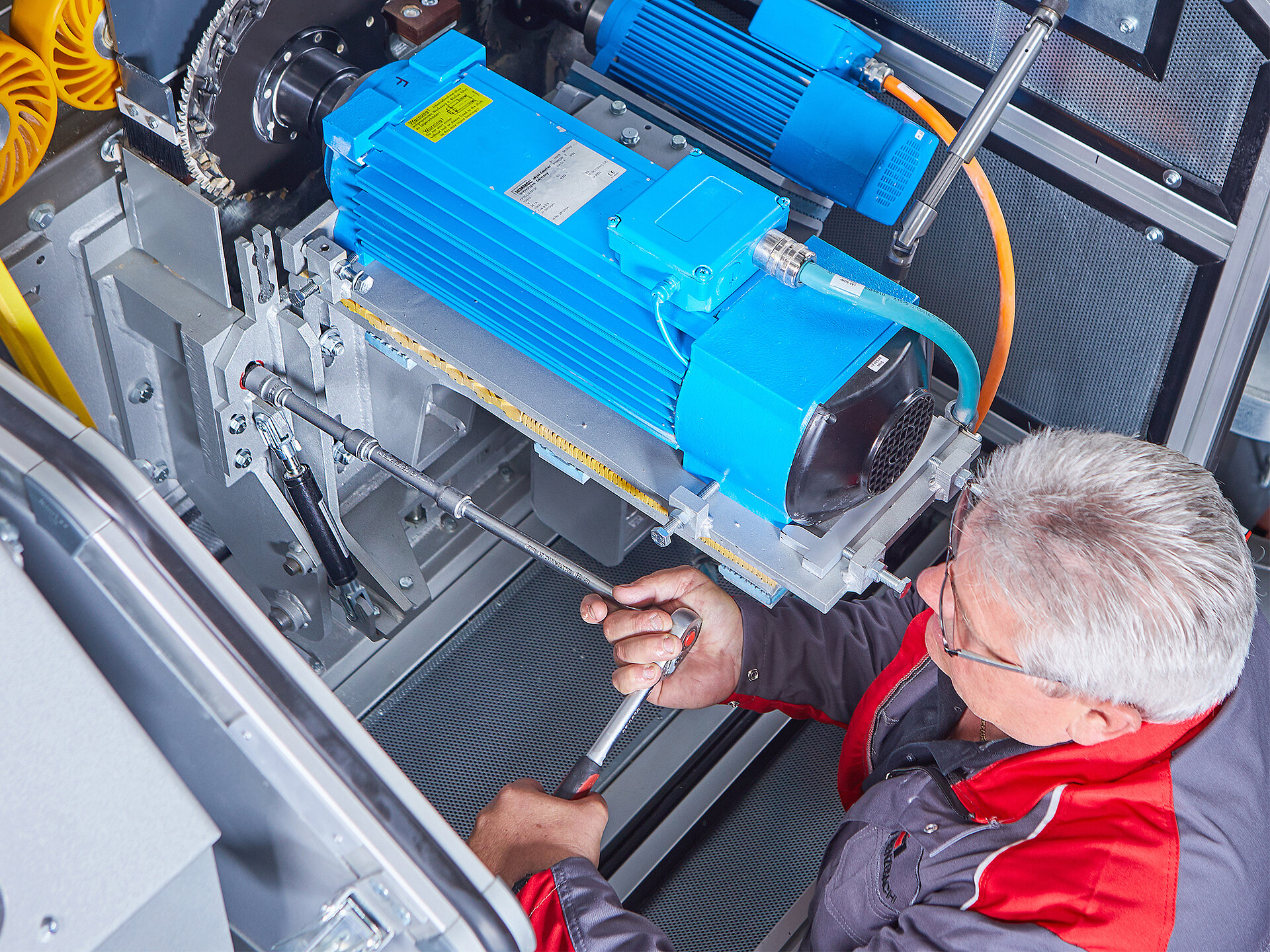

Grenzebach accompanies you with proven know-how and extensive experience throughout the entire block production process. Our technologies cover the preparation and forming of the materials as well as drying and packaging and all handling within the plant. We provide consulting services in our role as a full-service partner and deliver comprehensive services in the following areas:

- Raw material – analyses and supplementary practical tests

- Engineering – individual concepts and processes structured according to requirements

- Plant technology – high-precision dosing and process systems and requirement-specific degrees of automation

- Integration with your infrastructure – individual or full-line solutions that are optimally matched to your building and site infrastructure

and even more can be produced with our equipment.

Continuing Solutions

Your Contact Persons

Gypsum processing – a multi-layered process which we tailor to meet your needs. Get in touch!