What is friction stir welding? Explained easily – with video

In friction stir welding (FSW), metals are stirred, not melted. The friction stir welding process is particularly suitable for joining non-ferrous metals with low melting temperatures as well as mixed joints.

Definition: What is friction stir welding?

Process: How does friction stir welding work?

Definition: What is friction stir welding?

Friction stir welding is a pressure welding process. During this innovative welding process, metals are stirred at their seam with a rotating tool and – in comparison to the arc and laser beam welding processes – are not melted. The seam is heated but joined in a still solid state. Therefore, friction stir welding is in particular suitable for joining aluminum alloys, mixed joints and technically pure metals.

Process: How does friction stir welding work?

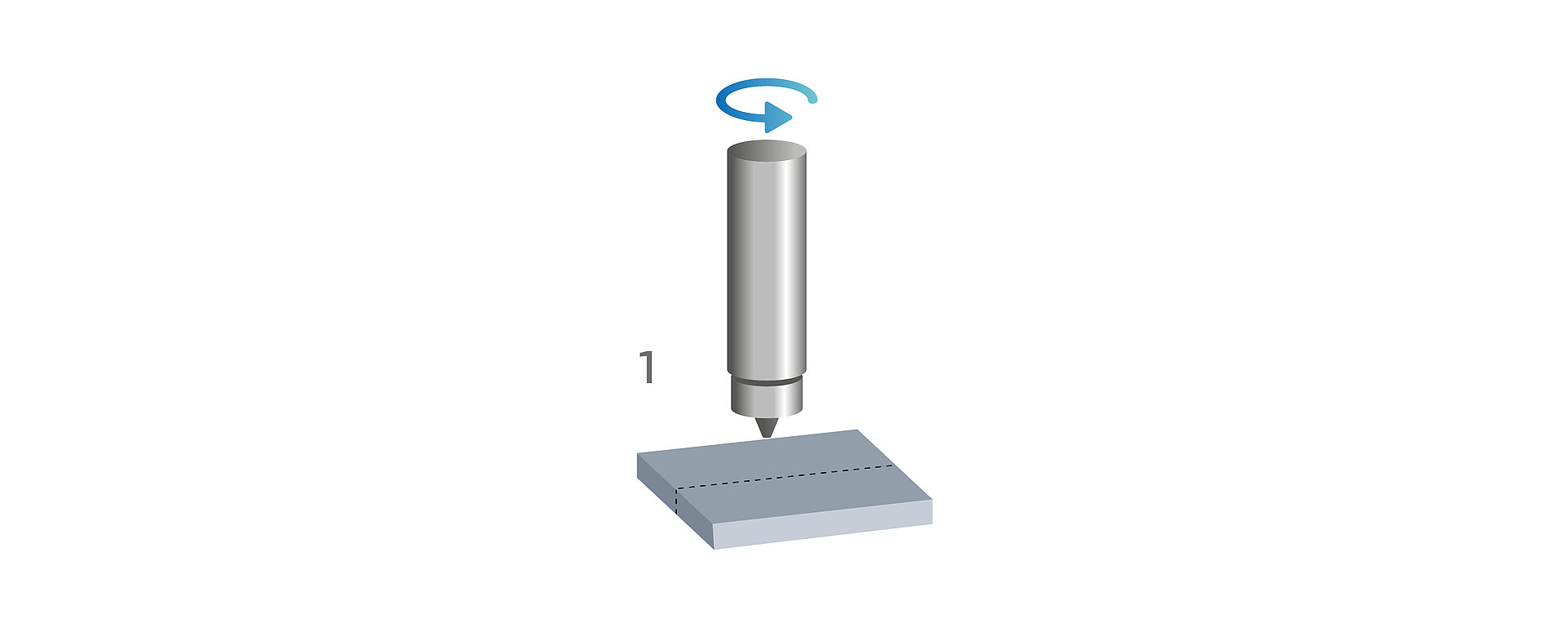

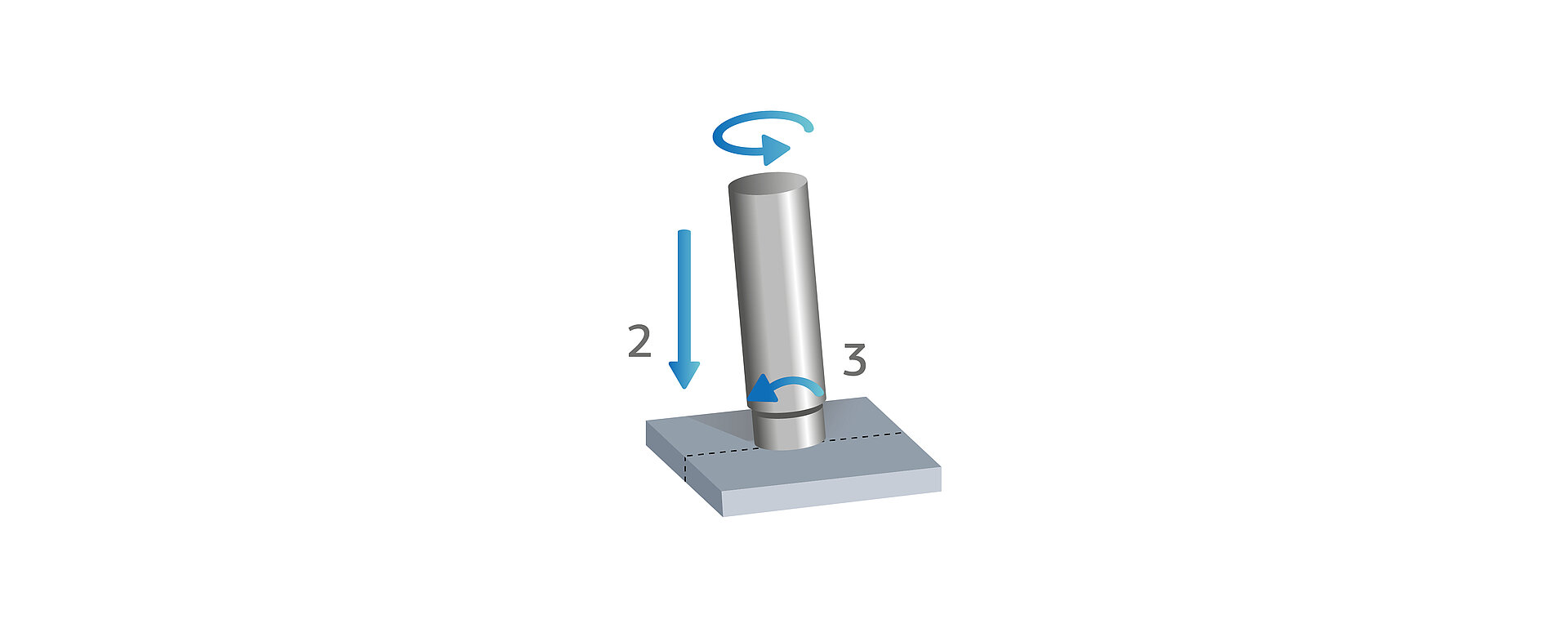

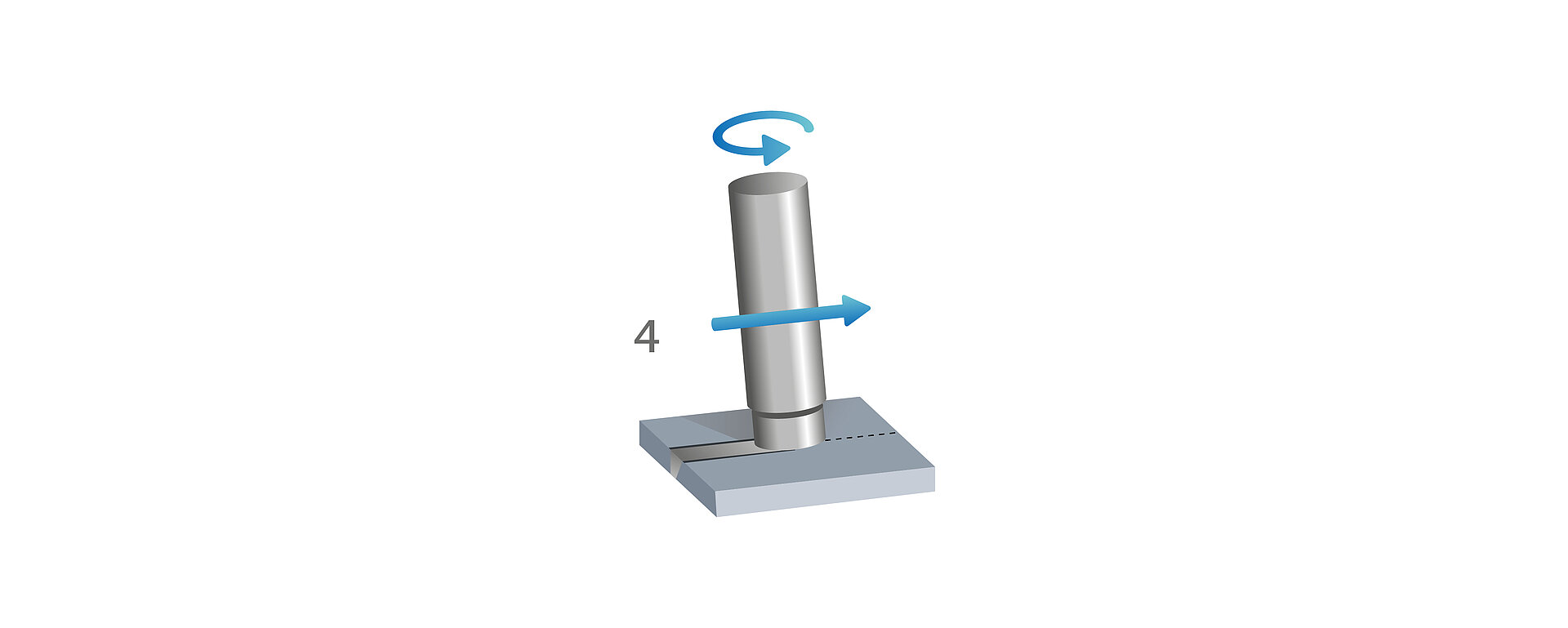

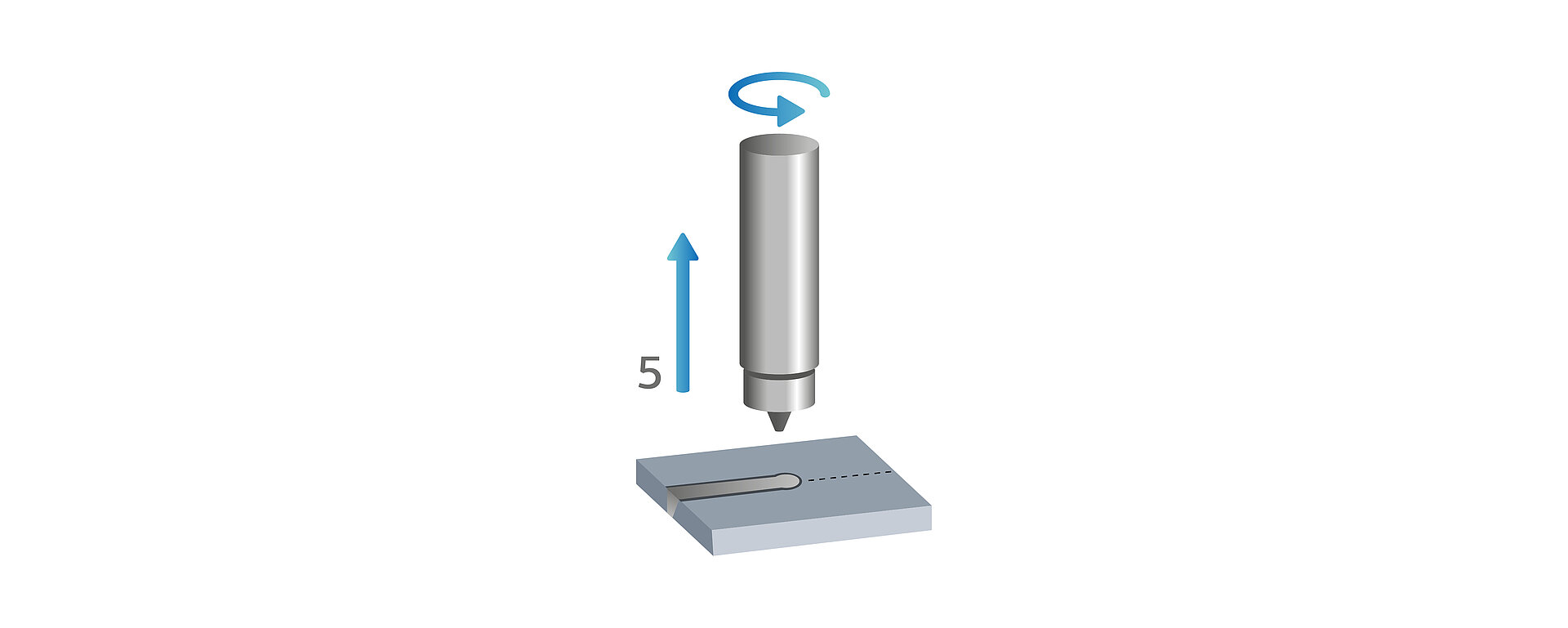

The classic FSW process is easily explained in four simple steps:

Application: What can be welded?

FSW is suitable for joining non-ferrous metals and alloys with low melting temperature and metallic mixed joints:

- Aluminum

- Copper

- Magnesium

Friction stir welding is particularly effective when processing aluminum: It enables the joining of aluminum alloys, e.g. the 3000, 5000 and 6000 series, which are considered to be non-weldable or difficult to weld. It is also an ideal process for welding mixed joints, such as aluminum sheets or extruded profiles with die-cast aluminum. FSW is more resistant against material defects such as pores, blowholes and fire cracks than, for example, the fusion welding process.

Friction stir welding is used in various industries:

- Automotive industry, in particular in e-mobility: Cast and extruded battery trays for hybrid and BEV (Battery Electric Vehicle) models, heat exchangers and power electronics.

- Power transmission/ power electronics

- Battery manufacturing

- Rail vehicle construction

- Aerospace and aviation

- Consumer electronics

Advantages: What are the benefits of friction stir welding?

Quality

Excellent welding quality

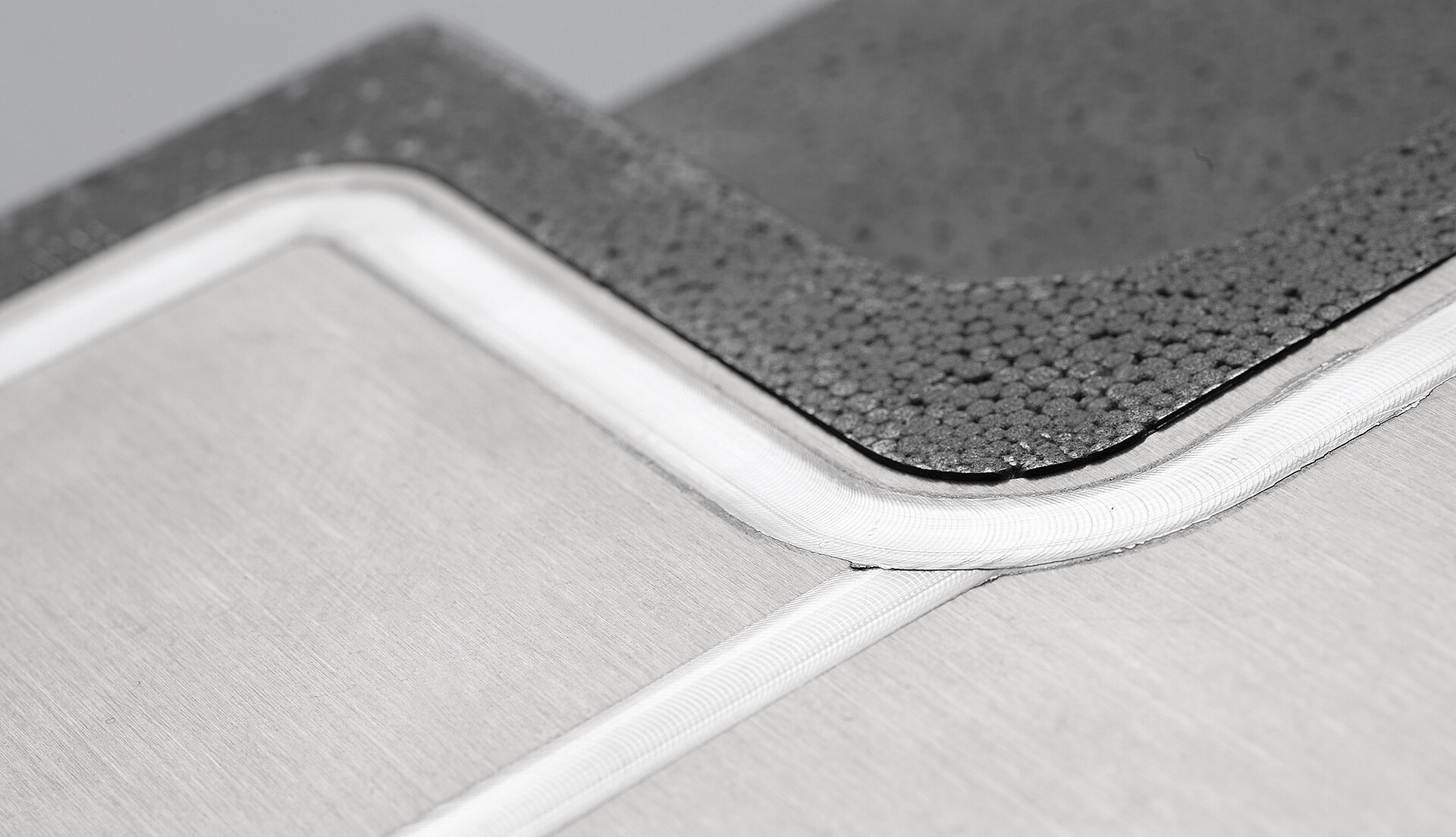

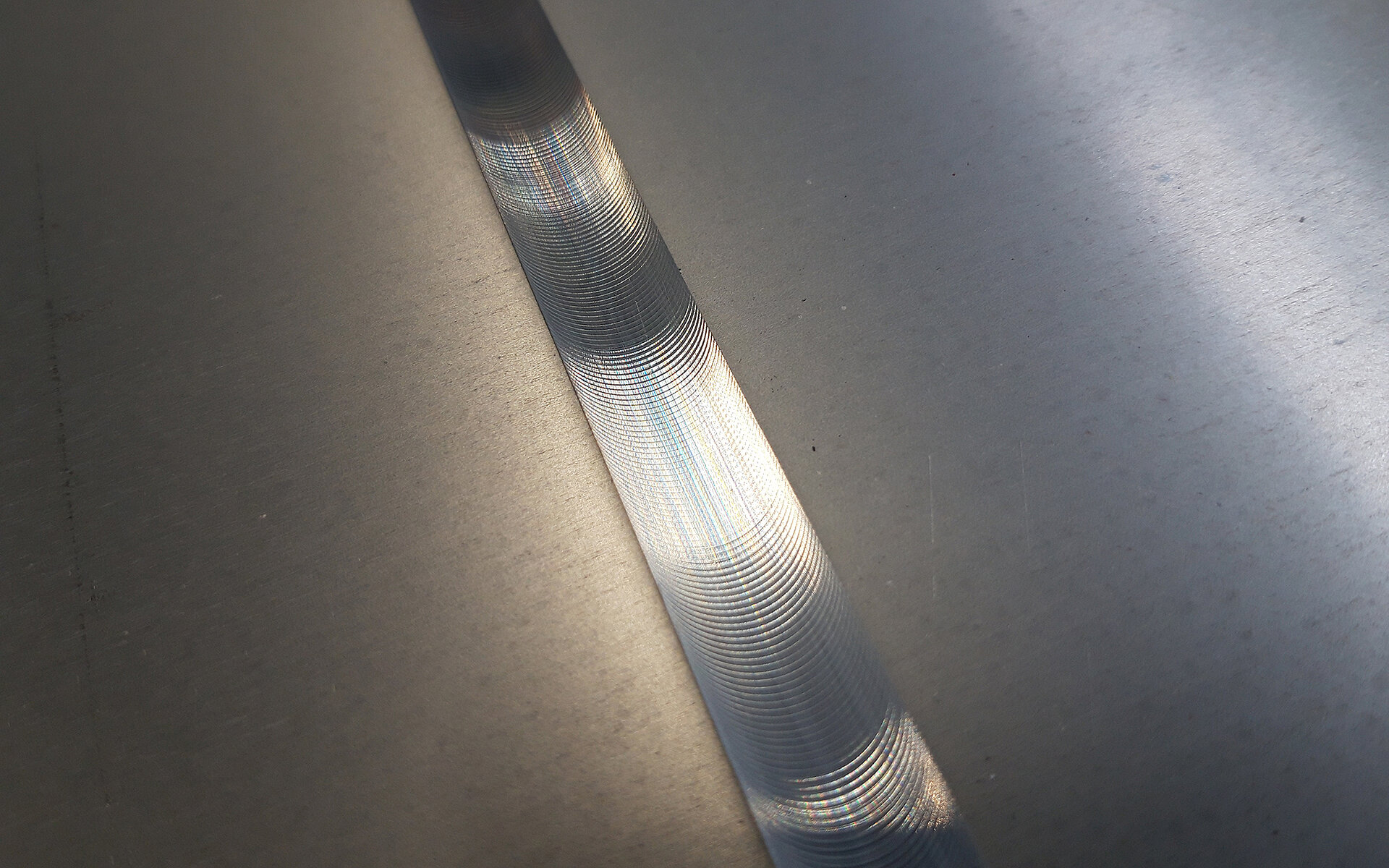

- Durable, media- and pressure-tight weld seams

- High, reproducible seam quality

- Robust, resilient and extremely load-bearing

- Low-warpage joints

- No pores or hot cracks, as the material has no liquid or vapor phase

Cost-effectiveness

Saves resources

- Need for purchasing and storage of operating materials is reduced, since auxiliary materials such as shielding gas, powder or welding wire are not required

- Low energy consumption compared to classic welding processes

- Low reject rates thanks to the high robustness of the process

- Less preparation and post processing of seams necessary

Environmental and health protection

Saves the environment and protects employees

- Emission-free

- Quieter than common welding processes

- No contamination by dust, gases, smoke, radiation

- No auxiliary materials necessary, such as shielding gas, powder or welding wire

- Essential step in the production of components for e-mobility (heat exchangers and battery trays)

Grenzebach – Supplier for turnkey plants

Grenzebach develops and supplies turnkey FSW plants – from gantry machines with customer-specific work areas to robots that can weld 3D geometries – and thinks ahead for the customers. Therefore, it is also key to consider the right technology of tools in addition to equipment technology. Based on customer requirements, the right friction tool is chosen: a one-piece (conventional) or multi-part tool (DynaSTIR) with a rotating friction pin and fixed shoulder.