POLYLINE project: entering the last phase

- The fifth consortium meeting of the POLYLINE project took place in Munich, Germany, in mid-July

- Tour of the equipment at the BMW AM Campus in Unterschleissheim, Germany

- A positive interim conclusion from the project participants and interested companies and partners from the industry

MUNICH, HAMLAR/Germany. The final phase begins – on July 19 and 20, 2022, the 15 industry and research partners of the POLYLINE project gathered for the fifth time at BMW in Munich, Germany. The agenda included a tour of the current POLYLINE installation at the AM (Additive Manufacturing) Campus in Unterschleissheim, Germany, and a presentation of each project partner's contributions and results. The meeting officially kicks off the final stage of the three-year project: During the next step, the prototype system will be transferred to a fully automated operation at the automotive giant BMW.

Efficient and safe Additive Manufacturing: Grenzebach's automation solutions

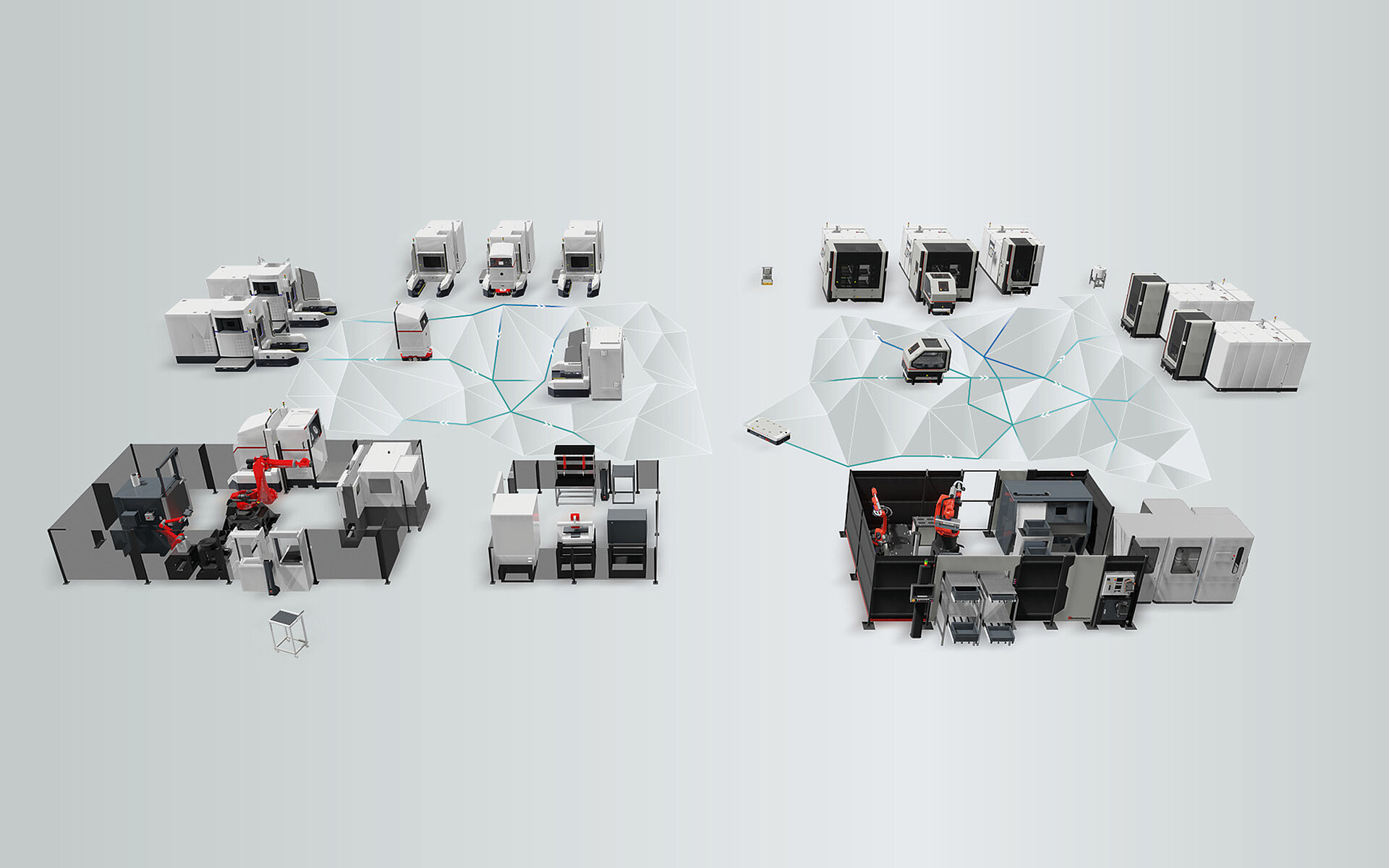

More than 35 industry and research participants took part in the fifth POLYLINE project meeting - including Grenzebach. The Hamlar-based company, a specialist in the automation of industrial Additive Manufacturing, provides the project with many years of experience and in-depth know-how in the intelligent and work-safe networking of manufacturing processes. Handling and bin-picking robots, exchange and transport solutions, and automated guided vehicles (AGVs) are used at POLYLINE and have been integrated into the overall concept by Grenzebach. Kurt Göpfrich, Project Manager Additive Manufacturing at Grenzebach, introduced the automation solution at the AM Campus to the consortium partners, the committee, and other interested companies and partners at the consortium meeting: "The feedback we received for our concept was thoroughly positive. We are delighted with the results."

POLYLINE is not the first research project for Grenzebach. In 2019, Grenzebach participated in the successful innovation project NextGenAM (Next Generation Additive Manufacturing) by supplying solutions.

“We strongly believe that projects such as POLYLINE or NextGenAM are a good way to demonstrate the potential for automation and industrialization of Additive Manufacturing sustainably.”

The POLYLINE project

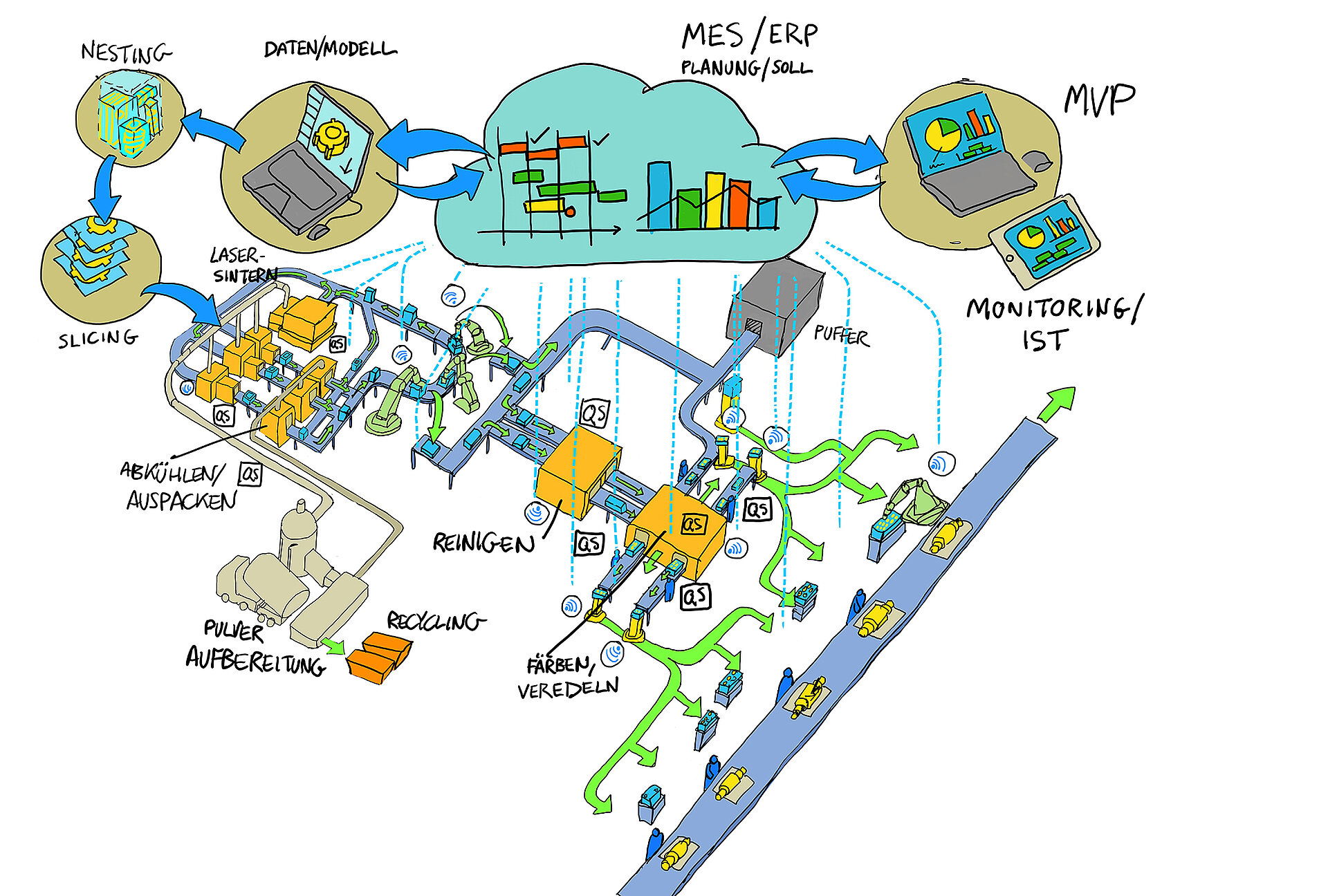

The POLYLINE (Integrated Production Line Applications for Polymer-based AM Technologies) automated production line will be used to manufacture plastic parts for the automotive industry. This will initially be installed at the Bavarian car manufacturer BMW. The goal is to enhance conventional manufacturing techniques (e.g. machining, casting, etc.) with Additive Manufacturing processes to enable future-proof, efficient, and high-throughput series production. The project was initiated in 2020 and is funded by the German Federal Ministry of Education and Research (BMBF). EOS, the world's leading technology provider in industrial 3D printing of metals and plastics and a long-time partner of Grenzebach, is in charge of the project.