Lightweight construction using friction stir welding in the automotive industry

- TPV AUTOMOTIVE uses Grenzebach's friction stir welding (FSW) technology for the manufacturing of battery trays.

- In Slovenia, six FSW gantry machines are already welding the structure-relevant components for e-vehicles from renowned OEMs.

BREZICE/Slovenia. Helping to shape the future of mobility – for TPV AUTOMOTIVE, headquartered in Slovenia, this means manufacturing components for e-mobility, the driving with green electricity. Being a development, innovation and production partner for the automotive industry, TPV AUTOMOTIVE supports automotive manufacturers in electrifying their range of vehicles. When it comes to aluminum components for e-cars, such as battery trays, the TPV AUTOMOTIVE team demonstrates its technology and process expertise – also through using friction stir welding technology.

Welding mixed joints

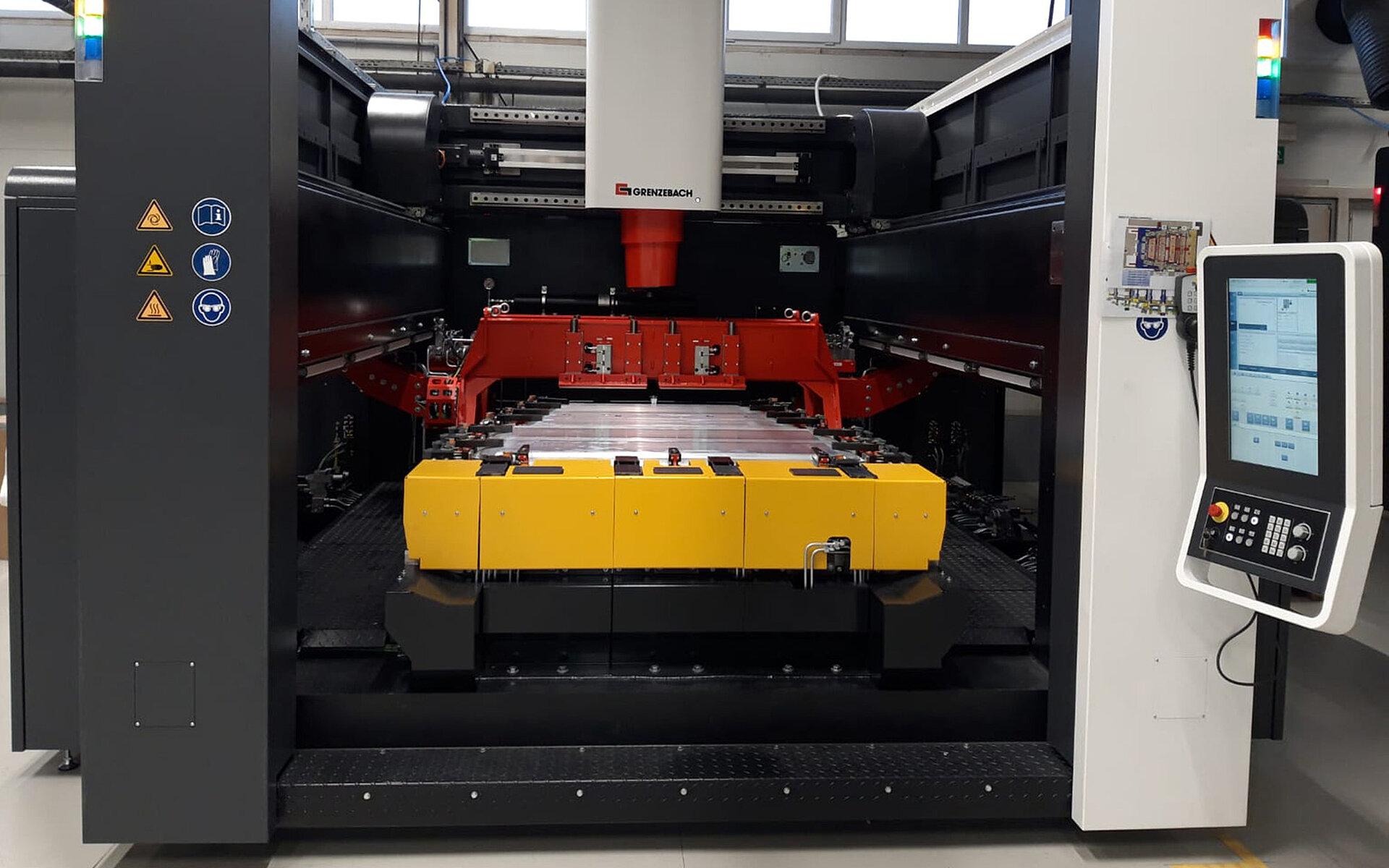

Six FSW gantry machines from Grenzebach are already in use for the production of battery trays for electric vehicles at the plant in Brežice near the Croatian border. The battery trays are manufactured from several individual components made of two different aluminum alloys. Cover plates and extruded profiles are welded together to form a battery tray.

Aluminum is known to be difficult or not melt-weldable at all, among other things due to its aluminum oxide layer. As a pressure welding process, friction stir welding is superior to other fusion welding processes when working with aluminum alloys and mixed joints. The components are not melted at the seam but stirred together. The seam is heated but joined in a still solid state.

"Alongside the high weld seam quality, the speed of the process steps is naturally decisive in serial production. Grenzebach's technology has completely convinced us with regard to these two important criteria," says Emir Šoštarec, Director of Supplier Quality Development at TPV AUTOMOTIVE.

Friction stir welding: a fast but also robust process step

Grenzebach's four-axis gantry systems guarantee absolute process reliability over the entire working range. The gantry system is designed for high axis dynamics and precise weld path guidance in the HYDROPOL® machine bed, which is specially designed for very high stiffness and low dynamic compliance and deformation. Due to the high welding depth, TPV AUTOMOTIVE uses the one-piece tool with rotating shoulder (MonoSTIR). A fast yet robust process that achieves reliable and repeatable weld quality across the entire working range. "The battery trays must be welded to be one hundred percent tight, so that no liquid can leak through should the battery be damaged", Emir Šoštarec explains.

Weld seams: extremely load-bearing and low-warpage

Friction stir welding can particularly show its strengths here. The rotating tool generates the required process heat through friction and pressure at the seam. The material becomes plastically deformable through the generated heat and is stirred by the rotating tool along the seam. The resulting seam is particularly tight. Because the weld seam is also extremely load-bearing, it can be used in structurally relevant areas. The high load-bearing capacity of the FSW seam contributes to the safety of the vehicle. The FSW joints are low-warpage thanks to the low energy input.

Friction stir welding: proven in serial production

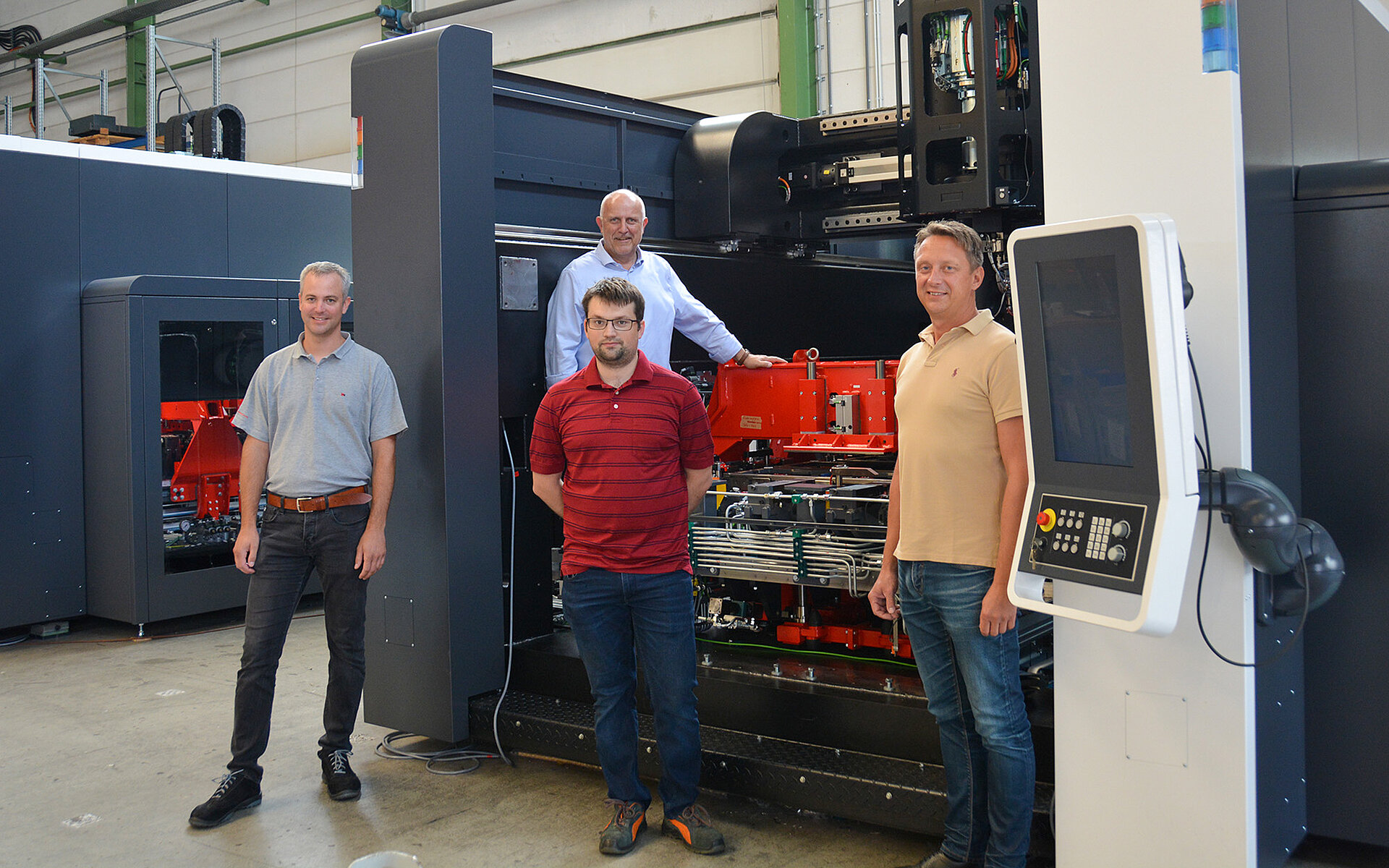

The TPV AUTOMOTIVE and Grenzebach experts met at the Aluminum trade fair in Düsseldorf in 2018 and started their cooperation. TPV AUTOMOTIVE ordered two FSW gantry machines back then. Since 2020, these are running at the Brežice site under series conditions in three shifts per day. The gantry machines are integrated in an automatic production line. A robot supplies the processing stations with components and feeds the FSW machines. "It proves how much the first two machines are paying off in serial production under demanding quality and time criteria that TPV AUTOMOTIVE has integrated four more friction stir welding machines. We are very happy that their production performance could be enhanced with FSW technology", says Andreas Preßlein, Project Manager at Grenzebach.

Prototype welding at Grenzebach

The collaboration between the two companies started with prototype welding at Grenzebach's headquarters in Hamlar near Augsburg, Germany. A TPV AUTOMOTIVE expert was on-site for that.

“Intensive professional sparring with our customers is part of our work philosophy. This way we get to know their exact needs and requirements and can adapt the technology individually and also jointly develop it further.”

Emission-free process for green mobility

Just as electric vehicles, aimed at climate-friendly mobility, are gaining importance, friction stir welding is being increasingly used for the production of aluminum components. An emission-free process meets low-emission drive technology. As opposed to conventional fusion welding processes such as arc welding, friction stir welding requires neither welding wire nor shielding gas or complex exhaust systems. In addition, the application is quiet and does not produce optical radiation.

Two global players in dialog

TPV AUTOMOTIVE and Grenzebach are both global players. TPV AUTOMOTIVE, headquartered in Novo mesto, which is located around 60 kilometers southeast of the Slovenian capital Lubljana and not far from the Croatian border, has five production sites in Slovenia, as well as sites in Serbia. The company has more than 60 years of experience in the automotive sector and currently employs more than 700 people. TPV AUTOMOTIVE exports its products to more than 20 countries, and numerous well-known automotive manufacturers are among the company's customers.

3,000 battery trays a week

With the six FSW gantry machines from Grenzebach, TPV AUTOMOTIVE can further enhance their active contribution to green mobility. One FSW gantry machine can produce about 80 battery trays per day. The six machines can deliver 3,000 parts per week.

Grenzebach provides a high-performance and emission-free process for the production of components for e-vehicles using FSW technology. OEMs and Tier 1 suppliers receive comprehensive advice on product design and process and can profit from a wide range of equipment and tools, which Grenzebach are continuously developing.