Configurable Control Processes: Roadmap for Intelligent Laser Structuring

The StabiLO research project at the Institute for Machine Tools and Industrial Management at the Technical University of Munich is focused on the process-stable laser structuring of metallic surfaces as part of Industry 4.0. The central hypothesis is that intelligent end-to-end process control enables the cost-effective, flexible and efficient production of 3D metal structures with fiber-reinforced plastics and increases process stability. The Grenzebach Maschinenbau GmbH is developing a continuous process control system that will allow adjustments to be made during the production process without interruption. The results indicate that intelligent control exceeds conventional systems and offers significant optimization potential. StabiLO's insights help to achieve the goals of sustainability, flexibility and safety optimization in production and form a solid basis for future technological innovations. Future research aims to extend the application to diverse materials and more complex geometries in order to meet the requirements of the industry.

1. Introduction

“Intelligent networking of processes is the key to Industry 4.0.” The StabiLO research project (process-stable laser structuring of metallic surfaces for large-scale joining of 3D metal structures with fiber-reinforced plastics) at the Institute for Machine Tools and Industrial Management (iwb) at the Technical University of Munich (TUM) is making this vision reality by researching intelligent end-to-end process control for the production of 3D metal structures with fiber-reinforced plastics1. Considering the growing demand for lightweight materials2, 3 and the necessity of economical series production4, it is of crucial importance to develop innovative approaches for process optimization5.

This article focuses on the hypothesis that intelligent end-to-end process control is more cost-effective, more flexible and more efficient than conventional process control via control elements. Research approaches5, 6, 7 have shown that conventional control systems often fail due to their transparency, flexibility and efficiency, especially in dynamic manufacturing environments such as in the aviation industry. The project team, consisting of iwb, Grenzebach Maschinenbau GmbH, Novanta Europe GmbH, and Airbus Helicopters Deutschland GmbH, is designed to address these deficits by, for example, establishing a high-performance process control system that enables adjustments to be made during production without interrupting the production line. This will involve implementing an innovative optical sensor concept and intelligent end-to-end process control, ensuring constant inline quality assurance and enabling end users to react more quickly to changing production environments and thus minimize waste.

This project, which was launched in March 2021 and completed in September 2024, comprises seven work packages ranging from laser structuring to the automation of data analysis1. The results are not only important for the partners involved, but also for the entire mechanical engineering industry, as they promise a sustainable and more efficient future for series production with minimal digitalization effort.

2. Procedure

In the course of the research project, a systematic approach was developed to create an in-depth understanding of the process for intelligent end-to-end process regulation. This approach is divided into several phases covering different aspects of laser structuring of metallic surfaces, inline topography measurement, data automation, intelligent process control and scaling of the joining process for an industrial application.

Intelligent end-to-end process regulation is based on the principles of end-to-end process regulation as described by Paul Harmon8 or Michael Hammer9, for example. It uses artificial intelligence (AI) technologies and methods10, automation and data analysis to control, continuously optimize and independently adapt processes from end to end5, 11. The following section takes a closer look at the procedure for developing such intelligent process control.

2.1. Framework conditions

The following framework conditions have been created to enable intelligent end-to-end process control in the project.

2.1.1. SERICY cluster with controller software

Basically, the intelligent process control is based on evaluated OCT sensor signals. Any deviations from the defined target topography caused by variables such as the heating of system components or fluctuations in the clamping of the components should be detected automatically. Control concepts will be developed to compensate for these deviations, enabling the adjustment of relevant process variables, in particular the laser power.

The controller algorithms are based on SERICY, the Grenzebach Maschinenbau GmbH digital ecosystem, which acts as a central interface for the involved components. SERICY consists of various applications as well as a modular IIoT platform and web environment12.

The controller software is part of the SERICY cluster, a compact and powerful Kubernetes cluster that runs the control algorithms and monitors the entire system. The controller software is designed to ensure control functionality. At the same time, it accommodates a neural network and covers other core features such as versioning and parallel provision of multiple AI models in ONNX format, parallel support of multiple control loops, dashboard functionalities for process control and validation of the controllers, freely configurable controllers (e.g., dynamic evaluation of the respective formulas, free determination of input and output parameters) and operations on complex objects (e.g., arrays and lists).

This is achieved by extending existing components and implementing the Control Loop component. The hardware was selected in a cluster of three passively cooled housings, each with 16 GB of RAM and 14 computing cores in order to achieve the necessary response times (in conjunction with the network hardware supplied).

2.1.2. Components

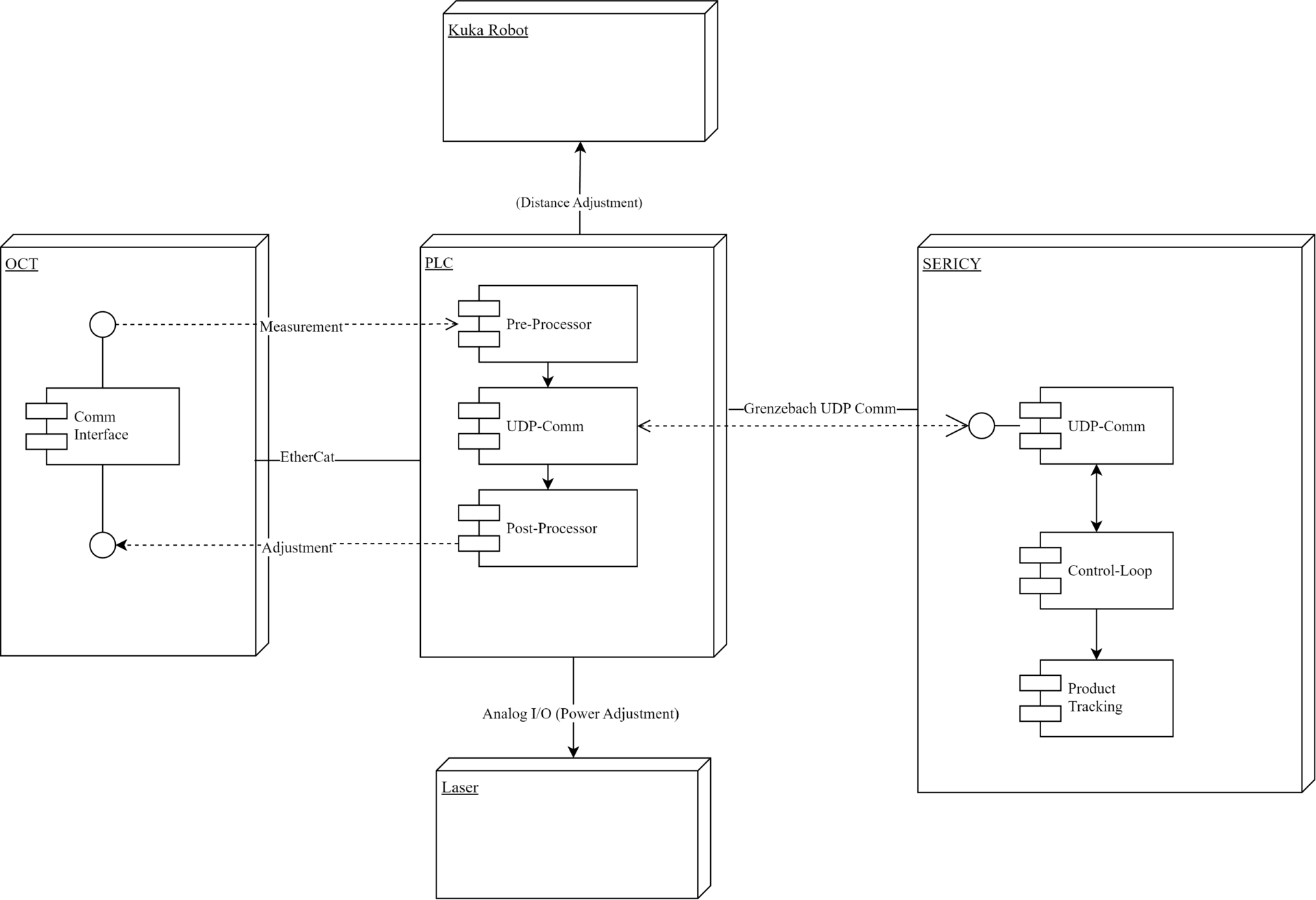

From the controller's perspective, the system consists of four other central components (see figure 1) that work closely together to control and monitor the entire process:

- OCT (Novanta): a high-resolution optical coherence tomography system that is used to monitor and validate the processing results

- Laser source: The main energy source and at the same time the location of the main control variable for the structuring process, which provides the laser beam that hits the component

- Multi-axis robots (Kuka): Industrial robot responsible for moving and positioning the laser head over the component

- Programmable Logic Controller (PLC, Beckhoff): the central interface for controlling the hardware components

The laser is controlled via an analog input, which is why the Beckhoff PLC is defined as the central element of data management. This collects, processes and distributes all relevant data to ensure efficient communication between the system components. Grenzebach developed a UDP-based protocol for data transmission between the PLC and the SERICY cluster, which is optimized in terms of packet size and transmission security. An existing library for Siemens controllers was ported to Beckhoff to enable integration into the Beckhoff ecosystem. The careful selection of communication protocols supports the flexibility and robustness of the entire system, even under varying process conditions.

2.1.3. Data transmission

The data packages were deliberately kept small to maximize the efficiency of the (de)serialization of measured values, which enables faster transmission. The control system not only handles the data transfer, but also the pre- and post-processing of the measurement data and its synchronization with the structuring process. These measures minimize the amount of raw data transferred by filtering irrelevant information and ensure that the data is available in a usable format.

The network cabinet supplied by Grenzebach was designed to be seamlessly integrated into the existing network infrastructure and has two network interfaces. These interfaces work as central nodes for data communication and ensure a clear separation between the laser cell's internal network and the operator's external IT infrastructure. The strict separation also enables secure remote access to the controller cluster via the Grenzebach service gateway. Access is limited to the controller cluster.

2.1.4. Power supply

This same principle of structural separation also applies to the system's power supply. The network cabinet was designed with an independent sub-distribution board in which all the necessary electrical components such as fuses, switches and distributors are integrated. The control cabinet was equipped with three mini IPCs for StabiLO and can be expanded and retrofitted at any time. Up to six mini IPCs could be installed in this project.

2.2. Control concept

The control concept is based on a multi-stage optimization approach. During the structuring process, the control initially only reacts to major material deviations; after completion, a high-resolution surface scan follows, which enables finer adjustments for subsequent structuring processes.

In order to minimize control delays, the maximum control range, for example for laser power, was limited to +/-1 kilowatt (kW). A function has been integrated into the second control loop, which interrupts the processing of the component as soon as disturbance variables exceed certain threshold values, as the StabiLO-OCT system cannot abort a structuring process.

2.2.1. Realized control loops

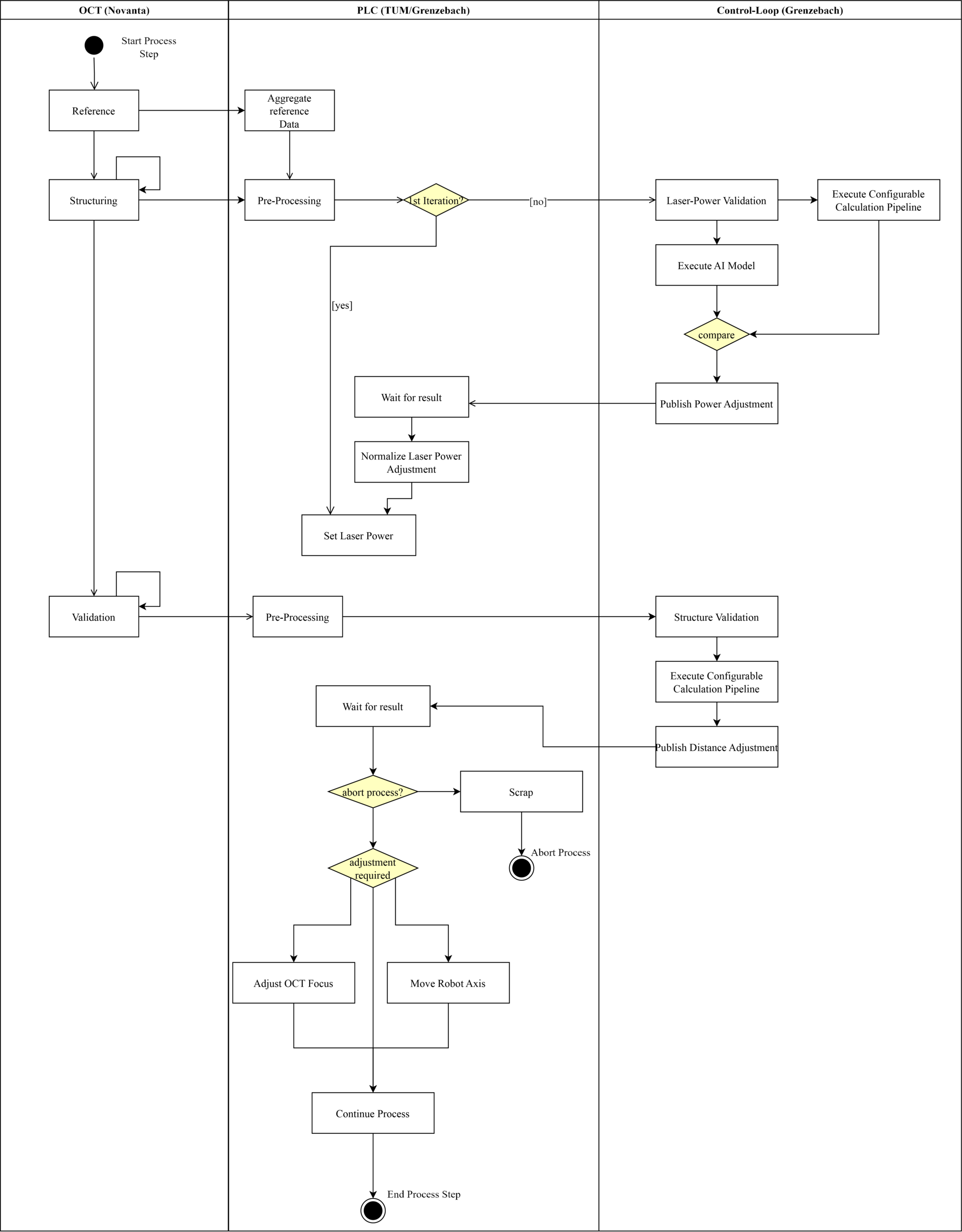

The entire process was divided into three main steps in order to manage the complexity of the process and optimize control (figure 2). The first step is to perform a reference run to determine the initial conditions of the system and perform the calibration. This step creates a baseline and ensures the correct initialization of all systems. In the structuring process, the main structuring process is undertaken, in which the relevant structures are created or edited according to the defined parameters. This step is repeated several times to refine and optimize the structure. In the final step, a validation run is conducted to check the results of the structuring process and ensure that all requirements have been met. Between the individual runs, the position of the component may need to be adjusted in order to optimize the precision and quality of the results.

A Grenzebach state machine records the necessary data during the reference, or homing run, which is then integrated into the structuring process and forwarded to the adaptable controller together with current measured values. The control software executes a pre-processing that normalizes the acquired data and reduces the communication between the controller system and the PLC to relevant data to ensure a response time of less than 5 milliseconds (ms) during the structuring process. During the validation run, longer response times of less than 20 ms are acceptable, as unprocessed raw data is required here in order to optimally prepare the upcoming structuring process. During pre-processing, 128 OCT height values are measured and then reduced to eight predefined, relevant values, including local maxima, local minima and the global ablation depth.

A different combination of this data is transmitted to the controller depending on the process step in order to increase flexibility and precision. The coordinates (X/Y/Z), laser power, noise distances and other process parameters are also sent to the controller. The content of the data packages could be adapted and expanded at any time.

The first control loop, which is active during the structuring process, focuses on the continuous adjustment of the laser power to the material conditions and process requirements. This control loop responds immediately to changes but is limited to the laser power to avoid interference from vibrations, as more in-depth adjustments, such as Z-axis adaptation, are not currently feasible.

In the validation phase, a more advanced control concept based on the high resolution of the OCT system is activated. The controller not only adjusts the laser power more precisely but can also adjust critical control variables and abort the entire process in the event of serious deviations in order to prevent damage.

The processing distance between the laser and the material is additionally fine-tuned, which is crucial for precision. The control software analyzes environmental variables and decides whether and how the Z-axis of the OCT system or the robot arm needs to be repositioned.

2.2.2. Adaptable control loops

The implementation of adaptive algorithms based on real-time data in order to react dynamically to changing process conditions is another important approach in the StabiLO project. In this way, simulations and model-based approaches can be used to test and optimize the controller performance as early as the project phase.

The data required for process control is obtained dynamically via a publish-subscribe model in the project's freely configurable control loops. This model allows the control loops to only request the data required for their specific tasks.

The received data is processed within the control loops with the help of freely definable formulas, using all the arithmetic operations provided by the microservice created in C#.NET. This includes mathematical, logical and statistical operations that can be adapted to the specific process parameters. These processes can be expanded on a project-specific basis - as in the case of integrating complex AI models into the control loop. The universal data format ONNX (Open Neural Network Exchange) was used. This format enables the direct integration of various AI models, such as neural networks and decision trees, into the control process. The AI models are either used for data preparation or, in this case, to compare current control and disturbance variables with the expected values of the neural networks. A model with 28 neural networks was implemented in the project in order to analyze the structures generated by the laser process and use them as a reference for the control system. This AI model identifies potential deviations at an early stage and automatically adjusts the process parameters.

The input parameters for the AI model include the structuring speed, the laser power and the number of traverses over the same region, as these factors directly influence the depth of material removal, a central criterion of laser structuring.

Several specialized neural networks are being used in the project, which autonomously calculate the expected removal depth for the respective conditions. Once the individual calculations have been made, a comparison and averaging phase is carried out in order to obtain a stable and reliable estimate of the removal depth. This sub-result is then combined with the actual process values, which include current material properties and environmental variables.

The controller software optimizes all the necessary calculations in advance, resulting in an exceptionally short latency time of around 1-2 ms—depending on the configuration of the controller—during the production process. The input and output parameters as well as the intermediate results of the control loop are visualized in various graphs using a dashboard.

3. Implementation and validation

Once the framework conditions for the implementation of an end-to-end control loop had been established, the next step was to validate the results from the other work packages of the StabiLO project, including the original prototype for pre-processing the input parameters in the form of a configurable neural network, together with Grenzebach and TUM, and transfer them into their final form.

The Grenzebach control system with user interface developed in the project was integrated into the controller provided by TUM by providing additional libraries. Grenzebach then installed the control system on the target hardware, integrated it into the plant network and put it into operation at the functional demonstrator location. In the last step, the control loop was configured together with the project partners and its functionality validated.

During the implementation and validation phase, the focus was on the following aspects:

- Implementation and validation of the selected algorithms: the algorithms were integrated into the software and checked for functionality and accuracy

- Testing the algorithms with real measured values: extensive tests were run with real measured values from selected structuring processes in order to evaluate the performance of the algorithms under practical conditions

- Data exchange via implemented interfaces: the data exchange via the newly implemented interfaces in live operation was tested to ensure that communication is efficient and error-free

- Provision of the required server hardware: the necessary server hardware has been provided and set up to meet the computing requirements of the controller system

- Integration of controller hardware: Integration of TUM's control hardware and Grenzebach's hardware was completed to ensure seamless collaboration and data transfer between the systems

4. Conclusion and outlook

The StabiLO research project has made significant progress, laying the foundations for end-to-end intelligent process control. Validating the hypothesis that such a control system is more economical, more flexible and more efficient than conventional control systems not only document the success of our research efforts but also represents progress in the area of Industry 4.0. This is because every manufacturing process has potential disturbance variables—positively influencing these or minimizing their effects leads to greater process stability, reliability and transparency.

This control software, developed on the basis of the SERICY digital ecosystem, enables precise real-time monitoring of the load structuring of metallic surfaces and opens up optimization potential in production for companies in a wide range of industries. The increased transparency and automated control systems based on mathematical models enable the end user to react more quickly to new situations and identify trends in their production plant at an early stage, which leads to a minimization of rejects. This increases not only the reliability of the system, but also the yield, which improves the user's competitiveness, especially in cost-intensive production processes. Traditionally, inline control systems in automation technology are implemented directly at controller or control level and are therefore limited in their reusability and flexibility. Intelligent end-to-end process control, as in this case, offers more sustainable and flexible software development at a superimposed process level, which saves costs in the long term. The use of adaptive algorithms reduces the need for programming knowledge on the part of the user and greatly simplifies the adaptation of the control loop, providing decisive flexibility compared to conventional solutions. In addition, the software developed enables the control loops to be visualized in various graphs. The graphical illustration makes it easier to understand and analyze the control states and promotes iterative improvement of the control loops, which also increases process stability and efficiency.

Furthermore, the level of (cyber) security is proving to be a critical factor in the development of safe, efficient and intelligent systems. This project therefore deliberately kept the network paths separate in order to enable secure remote access to the controller cluster and thus prevent unauthorized access to the entire network. The state-of-the-art network infrastructure allows the various networks to be operated in isolation so that faults in one network do not affect the others. The communication protocols used can also be defined for each network, which provides additional control and security and increases the efficiency and flexibility of communication between the systems. A similar separation was made for the power supply. As a result, only one central power supply needs to be connected on-site, which means there is no need for complex cabling of the individual components and reduces installation costs. This architecture increases operational reliability, since all connected systems have a central power supply. In case of an overload or short circuit of individual components, the integrated safety systems enable a quick shutdown without affecting the overall system, which increases both reliability and easy maintenance. The security measures implemented in the project to minimize cyberattacks and outages will continue to be evaluated and optimized in order to meet the challenges of an increasingly networked production landscape in the future.

Future research will also focus on expanding the technology by integrating additional sensors to increase measurement accuracy and extend the standardization of process control to other materials and more complex 3D geometries. Furthermore, more in-depth research into applications in other industries such as the automotive, aerospace and mechanical engineering sectors could provide valuable insights. The modular and scalable system architecture can be adapted in a targeted manner to better meet different industrial requirements and further increase overall efficiency.

In summary, the project not only shows the possibilities of intelligent process control, but also forms a solid basis for future innovations in the industry, which are supported by flexibility, safety and sustainability in production. The developed technology can be quickly and easily applied to other industrial applications thanks to the modular and scalable architecture of the end-to-end process control. Industries that require stable and reliable production processes in particular benefit from this solution.

References

[1] TUM. StabiLO - Prozesstabiles Laserstrukturieren von metallischen Oberflächen zum großflächigen Fügen von 3-D-Metall-Strukturen mit faserverstärkten Kunststoffen, https://www.mec.ed.tum.de/iwb/forschung-und-industrie/projekte/lasertechnik/stabilo-prozesstabiles-laserstrukturieren-von-metallischen-oberflaechen-zum-grossflaechigen-fuegen-von-3-d-metall-strukturen-mit-faserverstaerkten-kunststoffen/; 2021 [accessed 01 October 2024).

[2] Grand View Research. Lightweight Materials Market Size, Share & Trends Analysis Report, By Product (Composites, Polymers, Metals), By Application (Automotive, Aerospace, Energy), https://www.grandviewresearch.com/industry-analysis/lightweight-materials-market; 2023 [accessed 1 October 2024].

[3] MarketsandMarkets. Aerospace Lightweight Materials Market by Type (Titanium Alloy, Steel Alloy, Aluminium Alloy, Composite, Super Alloy, Others), Platform (Commercial Aviation, Military Aviation, Business & General Aviation), Application (Exterior, Interior), End Use (Commercial, Defense) and Region – Global forecast to 2025, https://www.marketsandmarkets.com/Market-Reports/aerospace-lightweight-material-market-131541377.html; 2024 [accessed 1 October 2024].

[4] Manyika J, Sinclair J, Dobbs R, Strube G, Rassey L, Mischke J, et al. Manufacturing the future: The next era of global growth and innovation. McKinsey & Company 2012. https://www.mckinsey.com/industries/advanced-electronics/our-insights/the-future-of-manufacturing.

[5] Ghosh B, Prasad R, Pallail G. The Automation Advantage: Embrace the future of productivity and improve speed, quality, and customer experience through AI. New York: McGraw Hill; 2022.

[6] Bugra A, Daniela V, Mussawar A, Bilal A, Robert H. Complexity in manufacturing systems and its measures: A literature review. European J. of Industrial Engineering. 2018;12(1):116-150. http://dx.doi.org/10.1504/EJIE.2018.089883.

[7] Rahmani M, Romsdal A, Sgarbossa F, Strandhagen J O, Holm M. Towards smart production planning and control: a conceptual framework linking planning environment characteristics with the need for smart production planning and control. Annual Reviews in Control. 2022;53:370-381. https://doi.org/10.1016/j.arcontrol.2022.03.008.

[8] Harmon P, Business Process Change: A Business Process Management Guide for Managers and Process Professionals. 3rd ed. Morgen Kaufmann; 2014. https://doi.org/10.1016/C2013-0-15339-1.

[9] Hammer M, The Agenda: What Every Business Must Do to Dominate the Decade. 1st ed. Three Rivers Press; 2003.

[10] Felzmann H, Fosch-Villaronga E, Lutz C, Tamò-Larrieux A. Towards Transparency by Design for Artificial Intelligence. Sci Eng Ethics. 2020;26:3333-3361. https://doi.org/10.1007/s11948-020-00276-4.

[11] Watson J, Schaefer G, Wright D, Witherick D, Horton R, Polner A et al. Deloitte Insights: Intelligent Process Automation: The Engine at the Core of the Digital Enterprise. Deloitte University EMEA CVBA. https://www2.deloitte.com/content/dam/insights/us/articles/73699-global-intelligent-automation-survey/DI_Automation-with-intelligence.pdf; 2020 [accessed 12 October 2024].

[12] Grenzebach Group. Digital Solutions, https://www.grenzebach.com/en/digital-solutions/; 2024 [accessed 28 September 2024].