Environmentally Friendly Use of Resources for Environmental Sustainability

As a matter of principle for the environment and nature

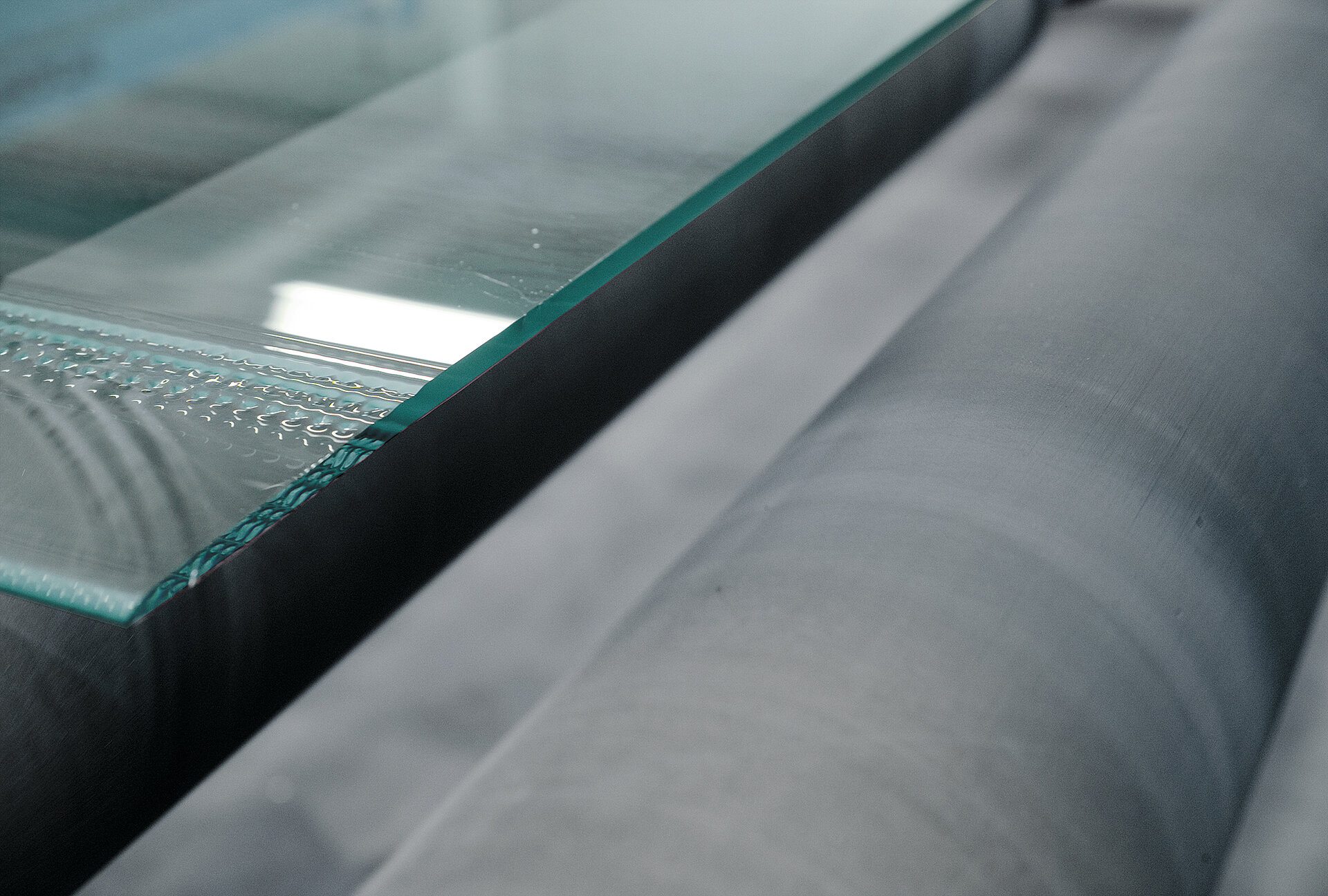

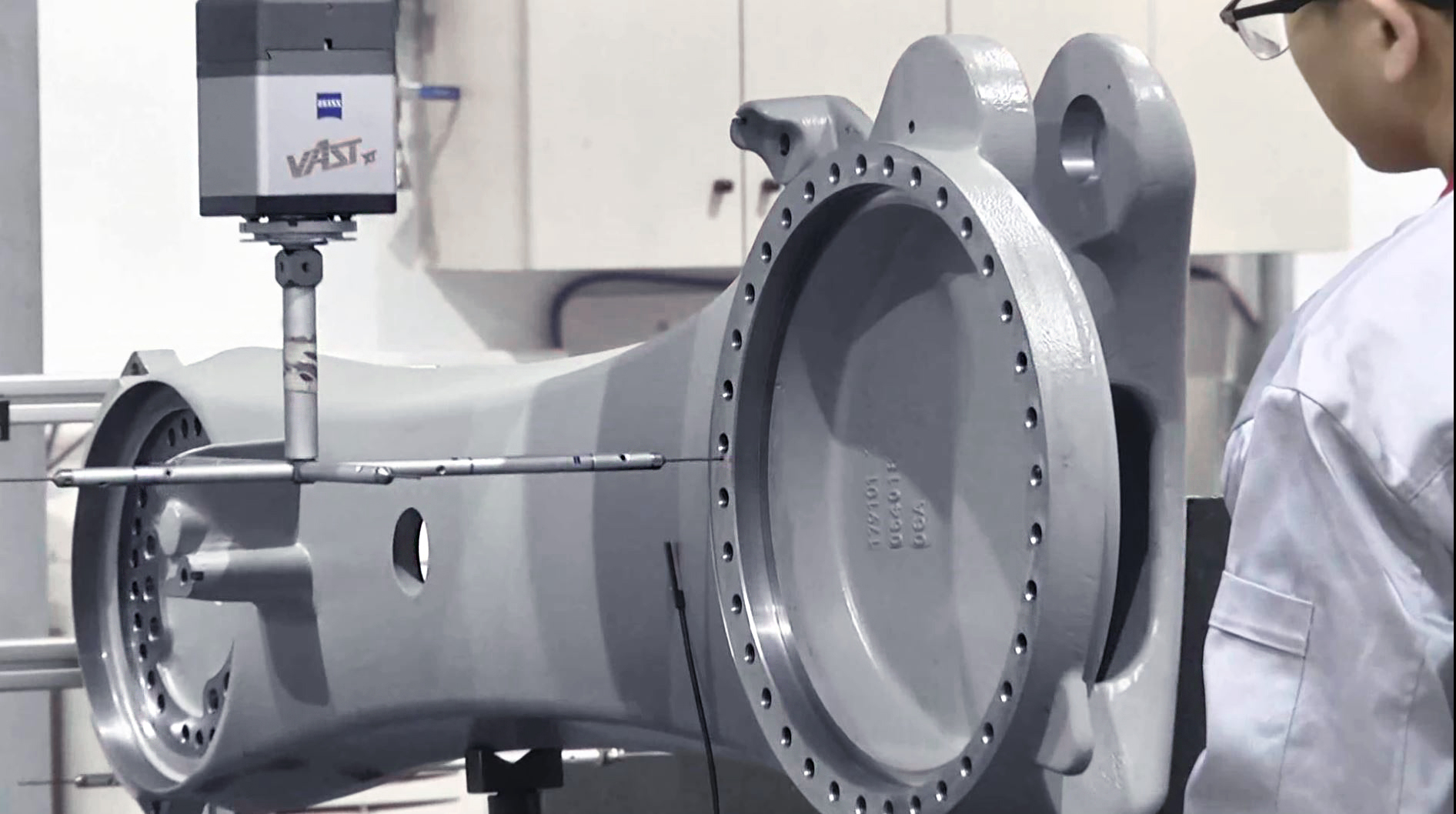

Sustainability manifests itself at Grenzebach in numerous different ways – from the foresighted use of resources to the use of environmentally friendly materials and products to the conscious use of energy. We aim to develop the best possible solutions for our customers while at the same time ensuring that technological progress is sustainable.

In practice, this means that we use resources carefully, both at our facilities and those of our customers. The Grenzebach Group’s environmental management system and energy management system foster our employees’ understanding of environmental protection and climate change mitigation worldwide in various areas.

We Promote Environmental Sustainability By:

- Using resources efficiently

- Using energy wisely

- Enhancing and minimizing our impact on the environment worldwide

- Taking proactive steps to protect the environment and combat climate change

- Ensuring that supply chains are sustainable

We review and implement sustainability improvements to our supply chains along our entire value chain to make each product and the company as a whole more climate-friendly.

Committed to a Healthy Environment and Sensible Energy Consumption

Our Environmental Management System

Taking a stand for greater sustainability – our environmental management system fosters employees’ understanding of environmentally relevant issues on the one hand and, on the other, helps us to be more proactive in protecting the environment at all our sites.

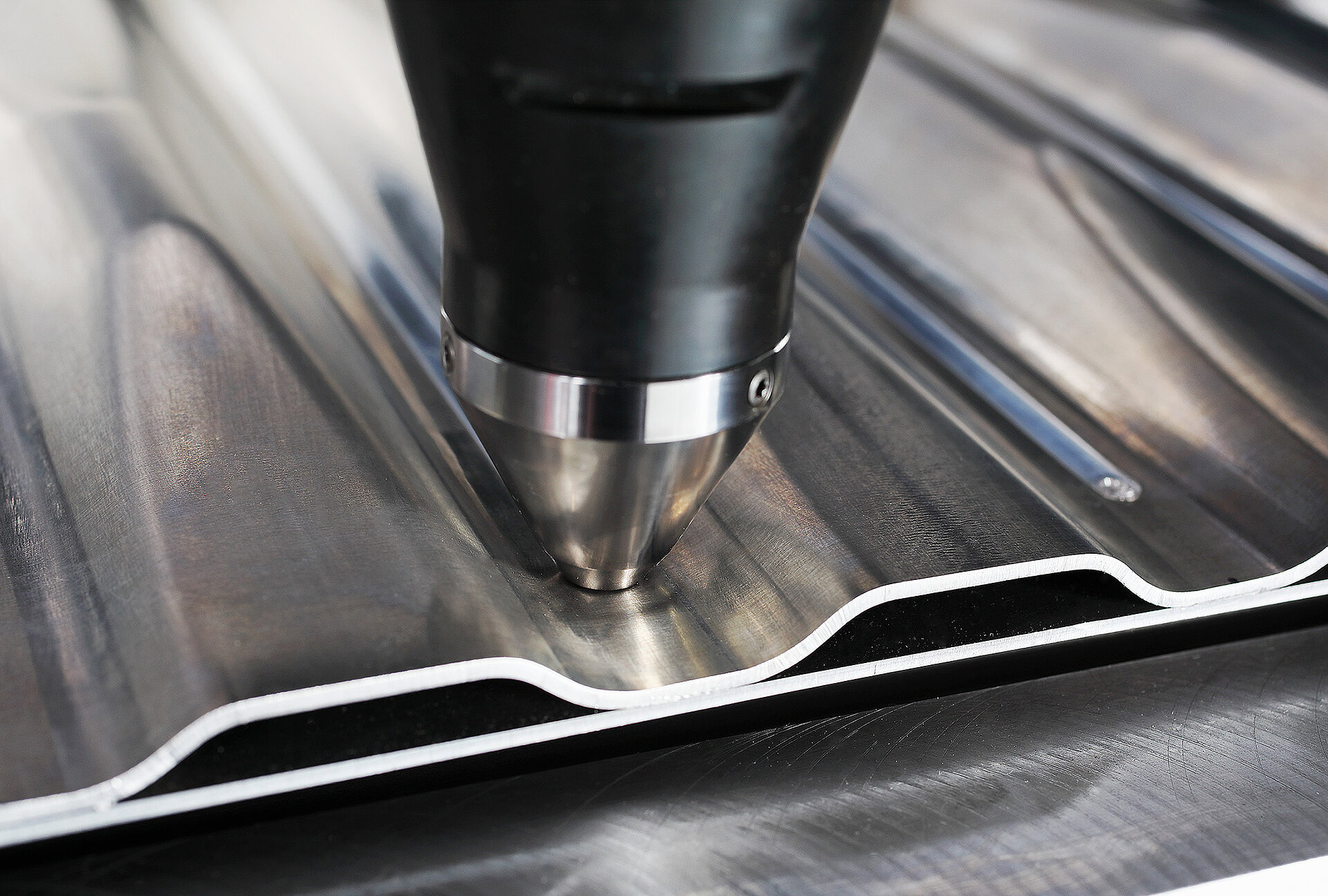

Grenzebach implements various actions to reduce its environmental impact over the long term. For example, we are constantly innovating in order to leverage energy-saving technologies for our machines and systems and maintain an open dialogue with the public.

Energy Management System

Our energy management system supports and fosters our employees’ awareness of our use and consumption of energy.

Our efforts facilitate ongoing and systematic improvements to our energy efficiency. For example, Grenzebach operates a 200 kWp solar power system on the roofs of its buildings in Hamlar for its electricity consumption and reduces wasteful electricity consumption by installing intelligent and resource-friendly air compressor systems.

How Does Grenzebach Contribute to Environmental and Climate Protection?

We’re happy to be here for you

Your Contact Person: Frank Wenger

Let us shape sustainability together. We will be happy to answer your questions about our economic, environmental and social responsibility.