Teamwork across continents keeps non-stop gypsum production running

Producing gypsum plasterboard non-stop, 24 hours per day, means facing new challenges in particular during this time marked by COVID-19. Contacts have to be reduced, travel restrictions are in place, supply chains are weakened - all that has an impact on gypsum production operations. In order to keep production running, existing plants still need to be serviced and optimized on a regular basis. Despite the restrictions, new plants and systems must be started up on schedule to make the investment profitable. Jobs to be done on the machines in particular require that supplier and customer cooperate in person on site. Working closely together while keeping a distance – a contrast that calls for new possibilities. To minimize the impact caused by the current situation and to be able to provide quickest possible support also in these difficult times, Grenzebach has further developed its collaboration resources. Grenzebach caters for its customers' needs in a number of ways to complete projects and commissioning jobs smoothly and without stoppages. Its global presence with locations in Europe, North America and Asia keeps up performance and ensures on-site availability and thus quick support when needed. Digital services allow Grenzebach experts to bridge physical distances and be close to the customer. Grenzebach assists its customers in a variety of different ways in their non-stop gypsum and plasterboard production and responds flexibly to changing circumstances:

Two high-speed plants started up on schedule in spite of the current challenges

A major project was initiated for the Xinfa Group in China at the end of 2020 in spite of the current conditions with the start-up of two high-speed gypsum plasterboard facilities. The project was in the middle of being developed when the pandemic broke out in early 2020. Grenzebach provided extensive assistance as the general contractor to prevent the project's progress from being jeopardized. In addition to all of the plant engineering, its array of responsibilities included plant planning, integration into the existing infrastructure, energy supply design, and development of the entire production and warehouse logistics. To implement the project while presented with the current challenges, Grenzebach in particular drew on its global presence. In a concerted transcontinental effort, Grenzebach experts at the sites in Jiashan, China, and Bad Hersfeld, Germany, collaborated closely on the project in order to execute plant installation and activation according to schedule. "Our top priority is not only to offer the customer an optimum technical concept, but also to provide them with the best possible assistance throughout all of the project stages," says Dr. Christoph Habighorst, Head of Sales at Grenzebach BSH. Thanks to the good collaboration of all the staff involved, Grenzebach was able to guarantee realization of the project in next to no time. "The efficiency of our international footprint takes full effect here," says Dr. Christoph Habighorst. The Grenzebach team took various steps to ensure that the project schedule was not jeopardized for Xinfa – with the Jiashan site being nearby, a number of local coworkers assisted with the plant's development and activation. Grenzebach also engaged in close dialogue with the authorities in order that the necessary specialists from Germany could enter China at the right time. The pronounced flexibility and close coordination of everyone involved in the project meant that the new gypsum plasterboard facility could go into operation on time at the end of 2020. The smooth progress made with the project under the currently challenging conditions, confirmed XINFA that they had chosen the right partner with Grenzebach.

“The collaboration based on partnership between Xinfa and Grenzebach demon-strates what can be achieved even in extraordinary times if we work together.”

Swift and straightforward assistance via the Collaboration App even in the event of unexpected downtimes

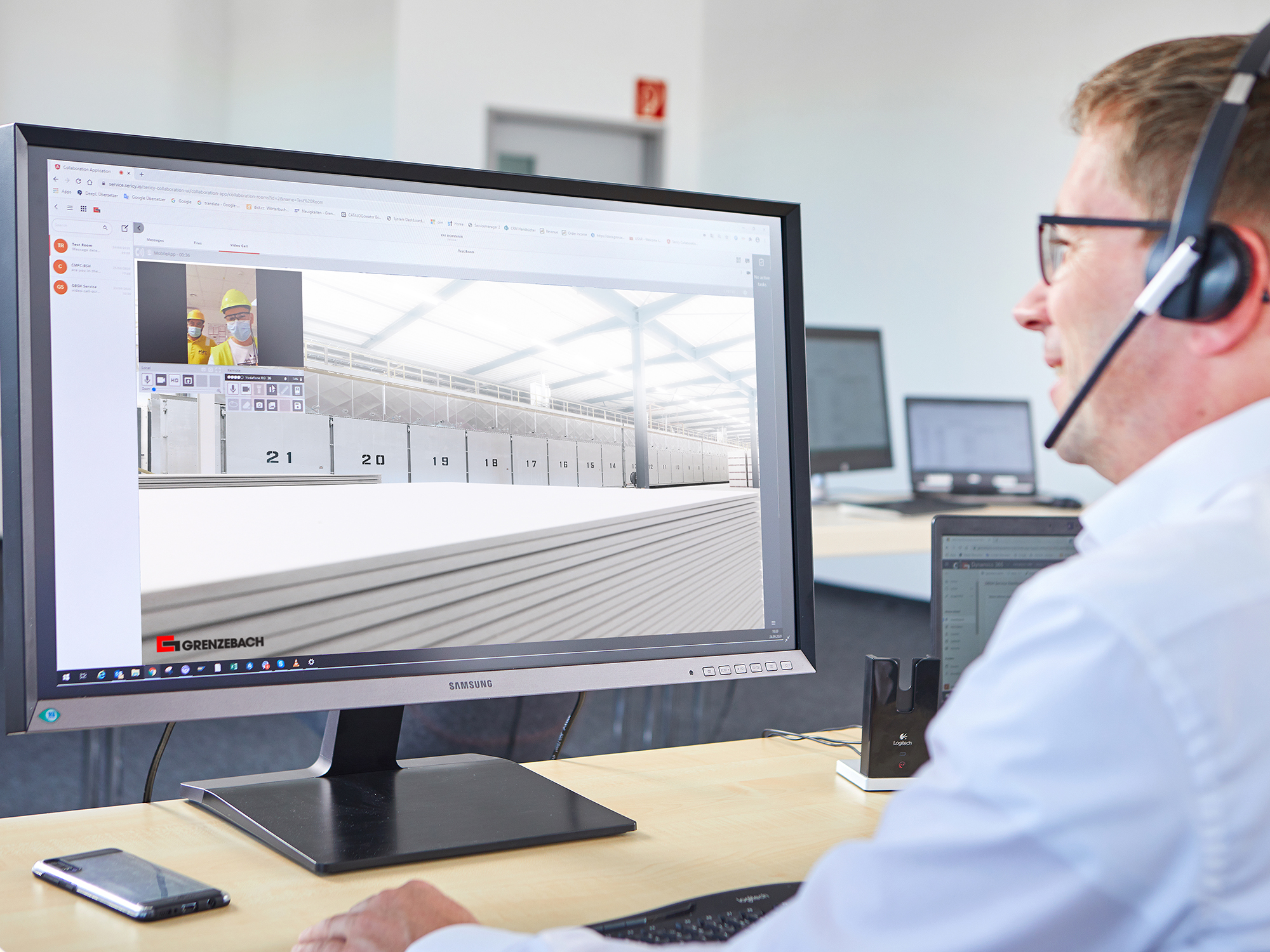

With its new Collaboration App, Grenzebach has also further bridged the gap digitally to its customers around the world in day-to-day business. Grenzebach experts are at the customers' disposal anytime and from anywhere via live video chat, in order for them to jointly take a direct look at a plant. The experts can provide audiovisual troubleshooting assistance and directly contribute to solving the problem by means of graphic annotations on the live picture. With the Collaboration App making support available quickly, customers are able to reduce unexpected downtimes. The direct support provided by the experts means employees can identify error causes quickly and easily trigger immediate spare part deliveries. Wolfgang Eydt, Head of Customer Service, Building Materials, emphasizes: "In these challenging times in particular, it is very important to us that we are there for our customers at all times – with highly practical assistance. The Collaboration App allows us to solve plant issues directly together with the customer. It's quick and straightforward."

Service without borders

From Germany to China and the whole world. Grenzebach secures its service through innovative ways. From upgrades via new product developments up to commissioning, Grenzebach experts are on the customers' side also in unusual times. "You Will never walk alone" – true to this motto we feel connected to our customers and want to collaborate with them even more closely. We want to be a sought-after partner to our customers," concludes Wolfgang Eydt.

Download Press Release: Teamwork across continents keeps non-stop gypsum production running