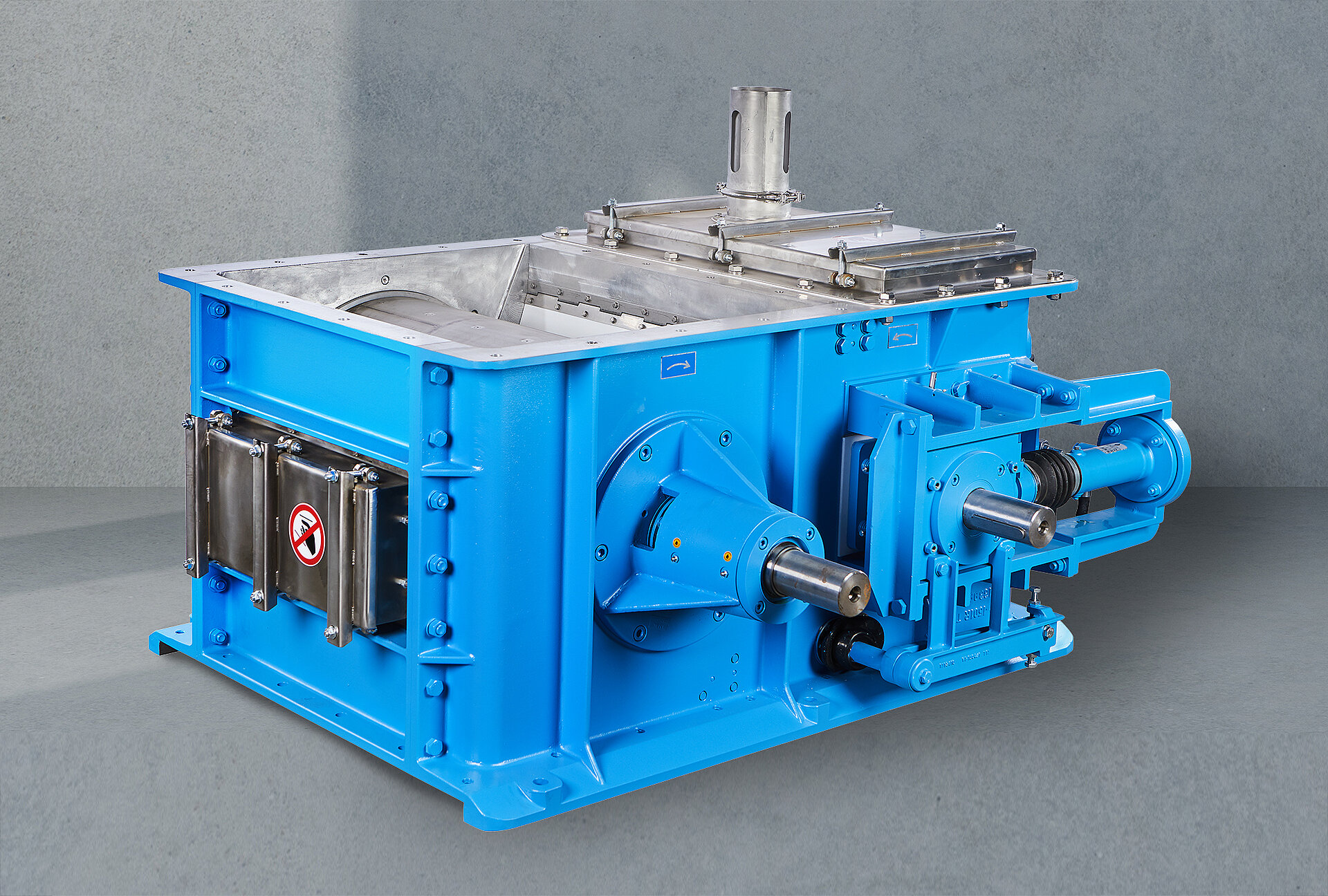

Popular in Japan: VACUPRESS systems from Grenzebach

Three further systems for deaeration and compaction of silicic acid are to be installed in Mid-2020 – strategic partnership with Matsubo

Japanese customers appreciate the performance and durability of Grenzebach VACUPRESS systems. Within three years, Grenzebach and its strategic partner Matsubo, a technology corporation headquartered Tokyo, have supplied six VACUPRESS systems for the Japanese market. In 2019 alone, three systems were sold. These will be put into service in Asia in 2020. "We are pleased that the VACUPRESS is so well received by Matsubo's customers. That underlines the outstanding position we have been able to establish with this technology on an international level," says Patrick Barthel, Sales Manager Process Technology at Grenzebach. Matsubo and Grenzebach have cooperated closely in a strategic partnership since 2018. Seiichi Yagasaki, Project Manager at Matsubo, emphasizes: "Our customers value the 'Made in Germany' quality of the Grenzebach VACUPRESS systems. The VACUPRESS stands out for its excellent performance, leading to excellent results, and its durability and long service life, which give its users an additional competitive advantage.“

A new trio for silicic acid compaction

The VACUPRESS trio to be delivered in Mid-2020 will be used for deaerating and compacting silicic acid, as are the three systems already running in Japan. Silicic acid is used for various purposes in chemical industry. In order to improve product handling and save storage and shipping costs, the silicic acid is deaerated and compacted using the VACUPRESS. The systems used densify the material at a factor of almost 1.5.

Reducing shipping and packaging costs

VACUPRESS systems are used for processing powders of less than 40 µm particle size and with bulk weights under 750 kg/m³. They serve as deaerators and compactors upstream from packaging equipment. Reduced shipping volumes and less dust generation as well as easier handling of the compacted products by the end users are clear practical benefits. Moreover, VACUPRESS systems can be used as metering systems for better integration of materials into downstream process stages, or as precompactors in combination with granulators.

Extra gentle product compaction

Reductions in volume of up to 75 % are achieved. Densification of the product is particularly gentle. The pressing forces applied in the VACUPRESS are relatively low and thus have only a minimal impact on the characteristics of the products treated. The product flakes and slivers produced can be converted back to their original fine powdered state at any time without having to apply strong shearing forces. The VACUPRESS is suitable for bulk weights of less than 750 kg/m³ and temperatures up to about 100°C. The main applications today are in the processing of silicic acid, carbon black, pigments, aluminium oxide and magnesium oxide. Grenzebach VACUPRESS systems are rated for operation in potentially explosive atmospheres in accordance with ATEX directives.

Cooperative partnership between Grenzebach and Matsubo

"The VACUPRESS helps to reduce shipping and packaging costs and improves product handling properties. From the outset we have placed great importance on a sturdy design and construction, allowing long service lives and minimising spare parts requirements," stresses Patrick Barthel from Grenzebach. In cooperation with Matsubo, work is already under way on further projects for the Asian market. In order to approach the target groups in the various industries together, Grenzebach participated at Matsubo's stand at the POWTEX trade fair in Osaka in late November 2019.

Download Press Release: Popular in Japan: VACUPRESS systems from Grenzebach