Best-fit systems from inos enable 100% in-line quality control for leading automotive manufacturer

- The best-fit systems from inos help BMW meet the stringent quality standards applicable in vehicle production.

- The best-fit solutions are now being used successfully in almost all BMW Group facilities and on the production lines for virtually all of its vehicle models.

- Approximately 110 sensors per model and production line take care that the components are aligned with the utmost precision and that all mounted parts are subject to a complete quality inspection.

STUTTGART/Germany. For 25 years, the automation specialist inos has been supplying customers with visionary system solutions. As such, the best-fit systems from inos integrated into the BMW Group’s production lines provide that the Munich-based automotive manufacturer can reliably manufacture its vehicles to an extremely high quality standard.

Production quality in almost all plants and all vehicles

Since 2008, inos has been integrating its best-fit systems into the production lines of the BMW Group and, as a long-standing partner at eye level, is a guarantor for optimized production processes. The sensor-based robot guidance systems from Stuttgart are now in use at five BMW Group facilities with car body construction and on the production lines for nearly all BMW Group models. And there will be more: A joint framework agreement secures the supply of best-fit equipment by inos until 2025.

Maximum precision and maximum quality control for vehicle assembly processes

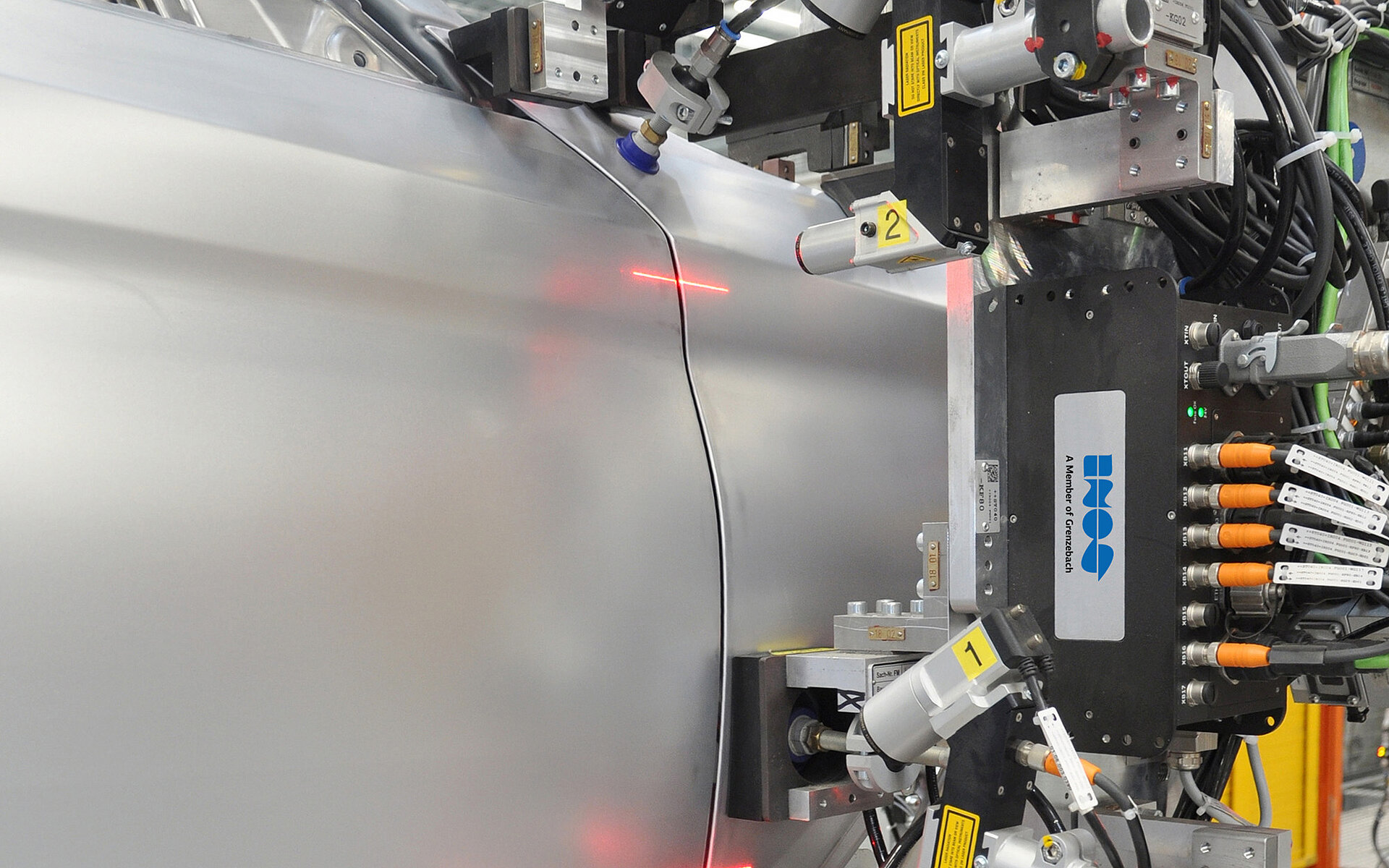

In automated vehicle assembly, components have to be mounted at numerous different points. Best-fit systems utilize high-performance vision systems and software technologies to achieve the highest level of precision during the alignment of all these components. The sensors, which are either stationary or mounted to the robots, measure the size of all the joints, transitions, and mounting dimensions during the component alignment process. The system compares the results with the nominal values in real time, calculates corrections, and adjusts the robot path accordingly – all with an accuracy of 0.2 mm or better. In this process, the quality level achieved is always inspected and documented directly on the lines.

Increased productivity and profitability for the BMW Group

By using the best-fit systems from inos, the BMW Group can maintain the quality of vehicle production at a high-end level and at the same time increase the productivity and profitability of the entire production. The systems integrated into the lines operate with high reliability, even at high production speeds, thereby helping to reduce cycle times to a minimum. Furthermore, the high level of quality minimizes the amount of subsequent work required to rectify errors. In addition, they can be configured with such flexibility that the production lines can be upgraded for use with new models or model versions quickly and easily without lengthy interruptions to production.

“This reliable combination of maximum precision and short cycle times is what makes the best-fit systems from inos so successful,” explained Karsten Trautmann, COO of inos. “It’s no coincidence that the BMW Group has been partnering with us for almost 15 years and will continue to integrate our systems into its production lines for many new vehicle models.”