119 tonnes on the road to Germany's northwest

- Valuable energy source: another Grenzebach sectional cooler for petroleum coke production completed

- Cooler to replace predecessor at a northwest German refinery

- Grenzebach provided continued support and assistance to the purchaser, from project planning through to commissioning on site

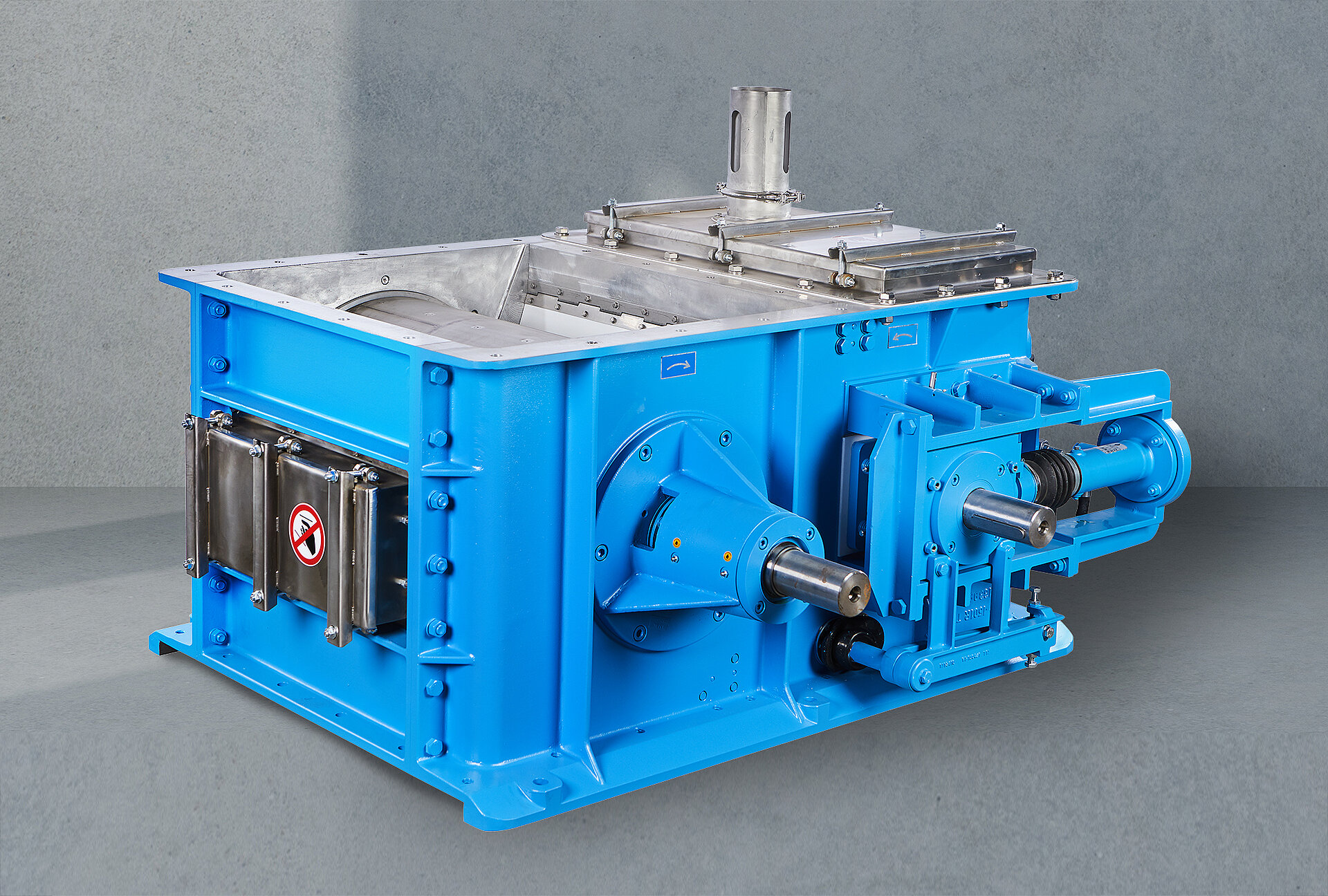

BAD HERSFELD, STRASSFURT/Germany. Grenzebach BSH, located in Bad Hersfeld, has delivered another sectional cooler for producing petroleum coke (also known as petcoke), a valuable fuel used in electric power stations and cement kilns, to a refinery in northwest Germany. The drum left the factory on an oversize load truck in September. The sectional cooler is to replace its predecessor, which had been running continuously for nine years. Among the items included in the Grenzebach BSH scope of supply for this job were the project planning, installation, and on-site commissioning of the drum.

High throughput and optimum cooling performance

“We have sized the sectional cooler precisely to match the refinery's current requirements and today's demands for sustainable energy generation. Our customer appreciates, in particular, the optimum cooling performance and the high availability of the system.”

Moreover, the drum does not need additional dust removal systems, which keeps capital costs low. "Apart from the superior cooling performance, that is another plus factor in the customer's view," adds Meyer. The new sectional cooler was completed and delivered within just seven months.

Essential in thermal process technology

In thermal process technology applications, products are heated to more than 1,000°C in kilns or calciners. To reduce the product temperatures, so-called sectional coolers are installed downstream from the kilns. Essentially, these are indirect heat exchangers designed as rotary drums. The drums weigh several hundred tonnes and often exceed 20 meters in length. Grenzebach sectional coolers stand out for their higher cooling capacity than other systems, which is reflected in the drum size.

The sectional cooler delivered recently operates at throughput rates of up to 25 tonnes of calcined petcoke per hour. The product is cooled down from 1,250 C to a maximum of 85 C in an indirect. parallel-flow process using cooling water supplied at 370 cubic meters per hour and a maximum temperature of 49 C. During the cooling process, the water temperature increases up to 75 °C by the time it leaves the cooler.

Petroleum coke: a highly stable, solid fuel

Cooled petroleum coke is a highly stable, solid fuel used worldwide in electricity generation and production processes. It is a rock-like residue from the oil refining process and consists of a complex mix of, mostly elemental, carbon and inorganic and organic compounds. Petcoke supplies valuable energy; some 80 percent is used as fuel for electric power stations and cement kilns. The remaining 20 percent goes into the production of anodes, which in turn are used to produce aluminum or recycle scrap steel. As a stable bulk solid, petcoke is ideally suited for transportation by ocean freight, inland waterways, railroad, and truck haulage.

Application-oriented process expertise and many years of know-how

With more than 300 sectional coolers supplied for processing various products and more than 270 employees, Grenzebach BSH stands for many years of experience and process technology know-how. The Grenzebach specialists use their in-house software solutions, which have proven their worth in numerous large-scale projects worldwide. In addition, the Grenzebach GBSH team is constantly thinking ahead to improve solutions and make processes even more energy efficient and sustainable for its customers.